- Introduction

- People

- Services

- Facilities

- Gallery

- Contact

Regional Centre, Rajkot has been relocated at 1st Floor, Centre of Excellence Building, Plot no.G-105 / A-1, Almighty Gate Road, GIDC Lodhika, Kalawad Road, Metoda , Rajkot – Gujarat in year 2023. Regional Centre has been established in year 2002 by CMTI, Bengaluru as a part of its outreach programmes and earlier was located in NSIC campus, Rajkot. Regional Centre provides Dimensional Metrology, Material Characterization Services, Training &Consultancy services.

CMTI established this Regional Centre in the year 2002, with an objective to support the industries in the Rajkot region in the field of Dimensional Metrology and Material Testing. Regional Centre Rajkot is supporting to various MSMEs in the region of Rajkot, Jamnagar, Bhavnagar, Morbi, Surendranagar, Jungadh, Gandhinagar, Ahmedabad other part of Gujarat & western region of India in the area of Material Testing, Metallurgical Analysis and Dimensional Metrology (Inspection & Calibration services). Centre provides the test/ calibration facilities with sophisticated Metrological Equipments and Material Testing Equipments.

| Centre Head | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

| Group Head | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

| Scientists | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

|

Mr. Abhishek Suchak | Scientist - C | View Profile |

| Technical Staff | |||

| Photo | Name | Designation | Phone (Office) |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

| Administration | |||

| Photo | Name | Designation | Phone (Office) |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

CALIBRATION CHARGES

A. MEASURING INSTRUMENTS

| Sl. No. | Name of the Instrument | Range | Charge ( Rs.) |

| 1. | Outside micrometer | 0-100 mm 101-200 mm 201-300 mm 301-500 mm |

250/- 325/- 375/- 550/- |

| 2. | Inside micrometer | 0-100 mm 101-200 mm 201-300 mm 301-500 mm |

250/- 325/- 375/- 550/- |

| 3. | Depth Micrometer | 0-25 mm 0-150 mm |

275/- 300/- |

| 4. | Setting Rods(For micrometer) | 50/- per rod | |

| 5. | Passameter | 25-150 mm | 350/- |

| 6. | Vernier Caliper | 0-150 mm 0-200 mm 0-300 mm 0-450 mm 0-600 mm 0-1000 mm |

250/- 300/- 350/- 400/- 550/- 850/- |

| 7. | Depth Vernier | 0-200 mm 0-300 mm 0-400 mm 0-500 mm 0-600 mm |

300/- 300/- 550/- 650/- 1000/- |

| 8. | Dial Caliper Gauge | 10-35 mm 30-55 mm 50-75 mm |

350/- 375/- 400/- |

| 9. | Pistol Type Caliper |

0 - 50 mm |

325/- |

| 10. | Vernier Height Gauge (Mech.) | 0 - 450 mm 0 - 600 mm 0 - 1000 mm |

600/- 600/- 1200/- |

| 11. | Vernier Height Gauge (Digital) |

0 - 300 mm 0 - 600 mm 0 - 1000 mm |

600/- 900/- 1500/- |

| 12. | Electronic Height gauge |

0 - 300 mm 0 - 600 mm 0 - 600 mm |

750/- 1200/- 1000/- |

| 13. | Plunger Type Dial Gauge |

0 - 10 mm 0 - 12.5 mm 0 - 20 mm 0 – 30 mm |

225/- 250/- 250/- 275/- |

| 14. | Lever Type Dial Indicator |

L.C.: 0.01 mm L.C.: 0.001 mm L.C.: 0.002 mm |

300/- 375/- 375/- |

| 15. | Dial Thickness Gauge |

0 - 10 mm | 400/- |

| 16. | Bevel Protractor |

0 - 360° | 600/- |

| 17. | Sine Bar |

100 mm 200 mm 300 mm |

350/- 450/- 600/- |

| 18. | Steel Scale | 0 - 300 mm 0 - 600 mm 0 - 1000 mm |

175/- 250/- 500/- |

| 19. | Steel Tape | 3 mtr. 5 mtr. 15 mtr. |

150/- 175/- 500/- |

| 20. | V-Block | - | 600/- |

| 21. | Spirit Level | 0.02 mm/m | 600/- |

| 22. | Frame Type Spirit Level (Box type) | 0.02 mm/m | 900/- |

| 23. | Bore Gauge | Up to 150 mm 150 - 400 mm 400 - 800 mm |

600/- 750/- 1000/- |

CALIBRATION CHARGES

GAUGES

AND GAUGING ELEMENTS

| Sl. No. | Name of the Gauge | Range |

Charge (in Rs.) |

| 1. | Plain Plug Gauge |

0 - 100 mm Dia. 101 - 200 mm Dia. 201 - 300 mm Dia. |

125/- 200/- 300/- |

| 2. | Plain Ring Gauge |

0 - 100 mm Dia. 101 - 200 mm Dia. |

200/- 450/- |

| 3. | Taper Plug/Ring Gauge | Any Range | 450/- |

| 4. | Snap Gauge |

0 - 100 mm 101 - 200 mm |

125/- 200/- |

| 5. | Feeler Gauge | - | 25/- per leaf |

| 6. | Slip Gauge |

Any Grade |

50/- per slip |

| 7. | Angle Gauge Block | - | 500/- per block |

| 8. | Thread Plug Gauge | 0 - 100 mm Dia. | 225/- per end |

| 9. | Thread Ring Gauge | 0 - 75 mm Dia. | 400/- per end |

| 10. | Straight Edge |

Upto 500 mm 500-1000 mm 1000-1500 mm |

800/- 1400/- 2000/- |

| 11. | Engineer Square |

Upto 500mm 500-900 mm |

1000/- 1500/- |

| 12. | Granite Square |

Upto 300 mm 300-500 mm 500-900 mm |

1800/- 2100/- 3500/- |

INSPECTION CHARGES/ MACHINE HOUR RATE

| Sl. No. | Name of the Instrument | Charge (in Rs.) |

| 1 | Co-ordinate Measuring Machine | Point Measurement: Rs. 825/- per hour Scanning Measurement: Rs. 950/- per hour |

| 2 | Roundness tester | Roundness Parameter: Rs.300/- Cylindricity Parameter: Rs.425/- Straightness Parameter: Rs.300/- |

| 3 | Spectrometer | Ferrous Materials: Rs. 250/- per Sample Non Ferrous Materials: Rs. 300/- per Sample |

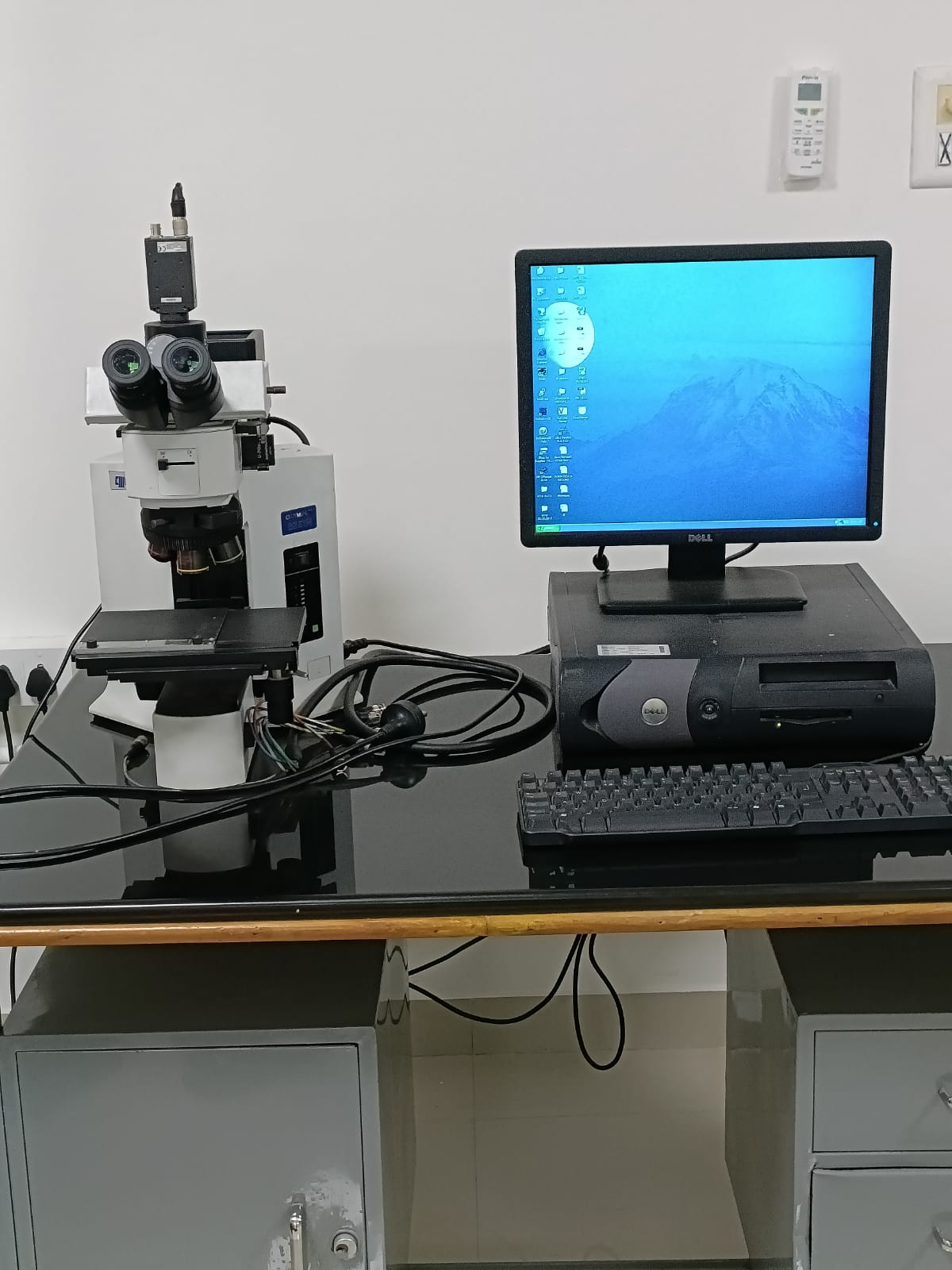

| 4 | Metallurgical Microscope | Rs. 300/- per Sample |

| 5. | Surface Roughness Tester | Rs. 250/- per Sample |

| 6. | Surface Plate (On-site Calibration) | Rs. 3,000/- per Half Day

Rs. 5,000/- per Full Day |

| 7. | Hardness Testing | Rs.250/- per Sample |

| 8. | Digital Height Gauge | Rs.600/-per hour |

| 9. | Length Measuring Machine | Rs.800/-per hour |

| 10. | Vision Measuring System | Rs.950/- per hour |

| 11. | Step Gauge (420mm) | Rs.12,000/- |

| 12. | Step Gauge(620mm) | Rs.18,000/- |

| 13. | Laser for Linear Measurement Local Outstation | 7500/- per day 13,500/- per day |

| 14. | Laser for Linear + Ball Bar Local Outstation | 9500/- per day 15,500/- per day |

| 15. | Laser for Rotary Axis Measurement Local Outstation | 8750/- per day 15,000/- per day |

| 16. | Ball Bar Testing Local Outstation | 5750/- per day 15,500/- per day |

| 17. | Laser for Linear+Geometric+Rotary axis Measurement Local Outstation |

11,250/- per day 17,500/- per day |

| 18. | Laser for Linear+Geometric Measurement Local Outstation |

9,500/- per day 15,500/-per day |

| 19. | CMM Calibration | 20,000/- per day |

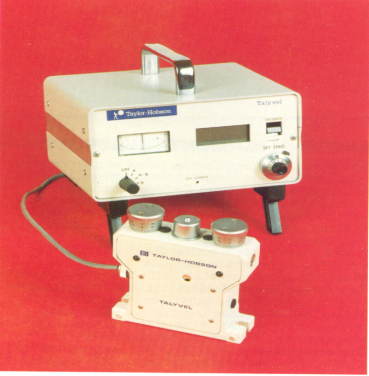

- Make: Taylor Hobson

- Measuring Range : 1000 arc sec

- Resolution :0.1 arc sec.

- Accuracy : ±2 % of full scale

Calibration of Granite Surface Plates, Spirit Levels, Measurement of Straightness, Flatness etc.

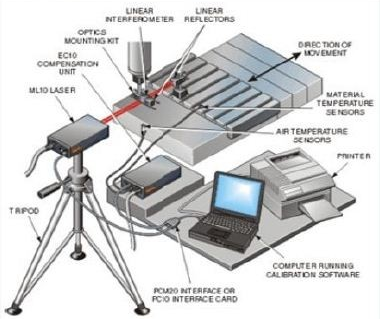

- Make: Renishaw

- Sensor resolution:- 1 µm

- Measurement Accuracy:- ± (0.7 + 0.3% L) µm

- Measuring Range:- ±1.0 mm

- Sensor stroke:- -1.25 mm to +1.25 mm

Calibration of CNC Machine Tools

- Make: Renishaw

- Laser Source :- Helium Neon laser tube (ClassII)

- Laser Power :- < 1 mW

- Vacuum Wavelength :- 632.990577nm

Calibration of CNC Machine Tools, CMM etc.

- Make: Ametek

- Channels:Fe, Zn, Al, Cu, Si

Meterial analysis

- Make: Octagone

- Range- 100 mm

- Resolution : 0.1 μm

Precision ID Measurements and Calibration of Ring Gauges

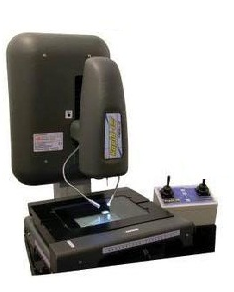

- Measurement Range- X-Axis – 200 mm, Y-Axis- 140 mm

- Scale Resolution: 0.5 μm

Micro Parts Inspection

- Make: Mitutoyo

- Traverse Length: 50mm

- Resolution: 0.125nm

Surface Roughness Measurement

- Make: Mitutoyo

- Range: X: 700 mm, Y: 1000 mm, Z:600 mm

- Resolution : 1 µm

- Size Measuring uncertainty MPEE :(1.9+ 3.0L/1000)µm

Inspection of components for Dimensional & Geometrical Parameters

- Make: Taylor Hobson

- Measuring Range:Length : 450 mm,

- Dia :290 mm

- Resolution : 1nm

- Spindle rotational accuracy : 11 nm

- Straightness of arm: 0.5mm

Form Measurements

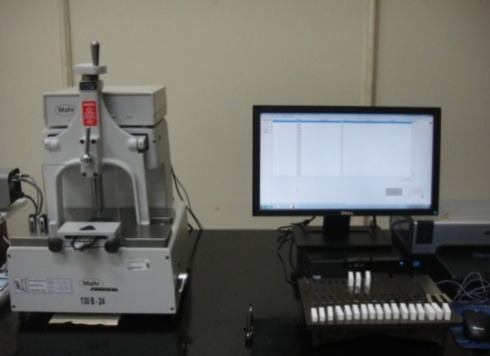

- Make: Mahr

- Measurement Range:100 mm

- Resolution: 1 nm

- Repeatability: 5 nm

Slip Gauge Calibration

Technical Queries

CMTI Regional Centre

1st Floor, Centre of Excellence Building, Plot no.G-105 / A-1, Almighty Gate Road, GIDC Lodhika, Kalawad Road, Metoda, Rajkot-360021 Gujarat

Phone: 02827-299485

E-mail: cmtirc[at]cmti[dot]res[dot]in

Scientist-C & Centre In-Charge

E-mail: abhishek[at]cmti[dot]res[dot]in

Phone: 02827-299485

Centre for Micro-Nano Manufacturing and Metrology (C-MNTM)

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru – 560022

Phone (Office): +91-80-22188379

Mobile: +91-9449842672

E-mail: niranjan[at]cmti[dot]res[dot]in