- Introduction

- People

- Research Areas

- Projects

- Services

- Facilities

- Achievements

- Gallery

- Contact

India is developing at a mind-boggling pace, with its strategic place as one of the world’s largest economies, it is in dire need of reliance on indigenous technologies.

CMTI’s Centre for additive and special manufacturing (C-ASMP) is a cluster of teams with a specific focus on Prototyping, product and testing technologies which cater to the very need as discussed.

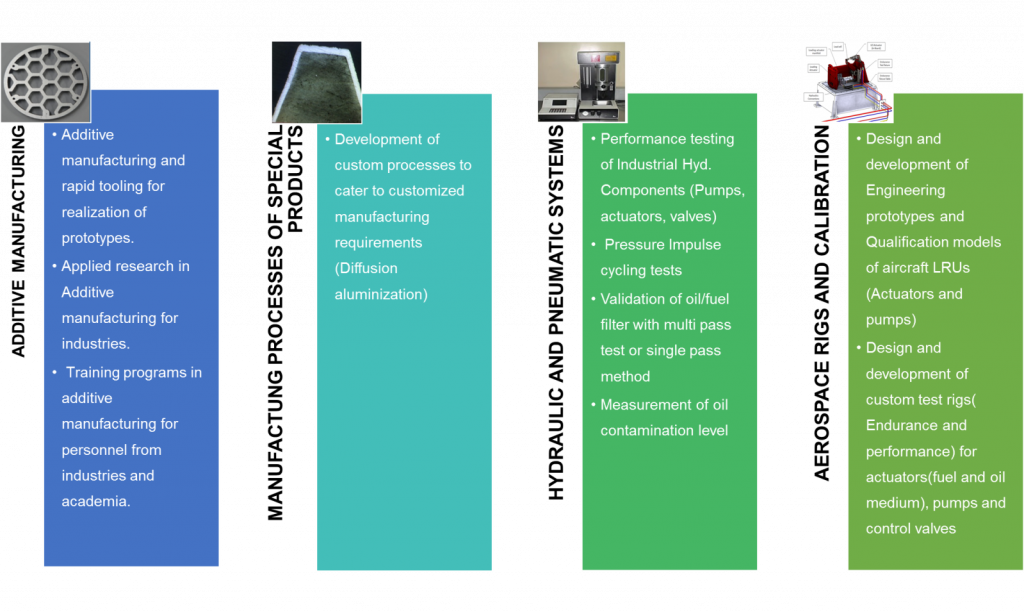

Core Competencies of C-ASMP are,

- Additive manufacturing

- Manufacturing processes of special products

- Hydraulic and Pneumatic systems

- Aerospace test rig and calibration

| Centre Head | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

|

Mr. Shanmugaraj V | Joint Director | View Profile |

| Group Head | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

|

Mr. Tom Thampy | Scientist - E | View Profile |

| Scientists | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

|

Mr. Anil Kumar K | Scientist - D | View Profile |

|

Mr. Vijet Bhandiwad | Scientist - D | View Profile |

|

Mr. Deepak Singh D | Scientist - C | View Profile |

|

Mr. Dattatreya | Scientist - C | View Profile |

|

Mrs. Shruthi G | Scientist - D | View Profile |

|

Mr. Emmanuel Gospel Raj R. | Scientist - B | View Profile |

|

Dr. Tapas Debnath | Scientist - C | View Profile |

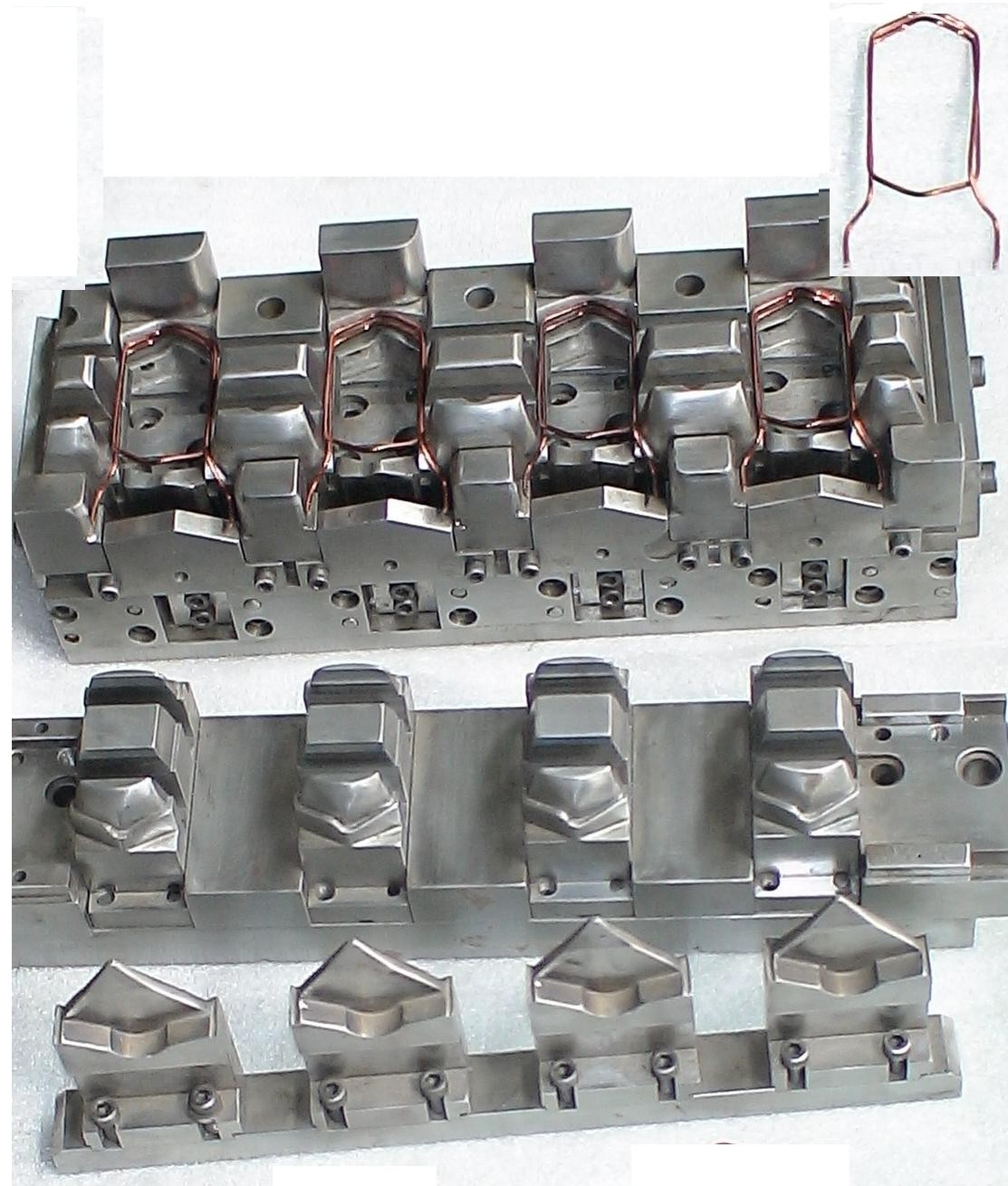

| Technical Staff | |||

| Photo | Name | Designation | Phone (Office) |

|---|---|---|---|

|

Mr. Bishnu Prasad Sahu | Senior Technical Assistant - II | 080-22188266 |

|

Mrs. Anitha Devi S | Senior Technical Assistant - I | 080-22188215 |

|

Mr. Manju M | Senior Technical Assistant - I | 080-22188352 |

|

Mr. Girisha C V | Technical Assistant | 080-22188239 |

|

Mr. Sandeepa K R | Technical Assistant | 080-22188215 |

|

Mr. Prakash V S | Technician III | 080-22188318 |

|

Mr. Tharanatha P | Technician III | 080-22188239 |

| Administration | |||

| Photo | Name | Designation | Phone (Office) |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

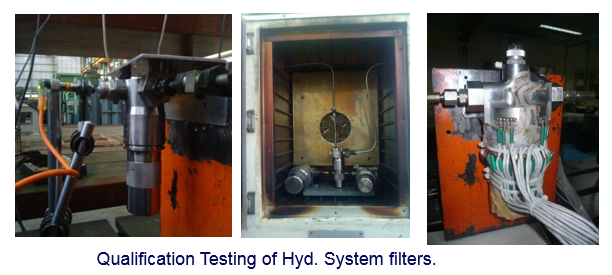

- Qualification Testing of Aerospace Hydraulic Components as per Military Standards.

| Sl. No. | Name & Description | Photo |

|---|---|---|

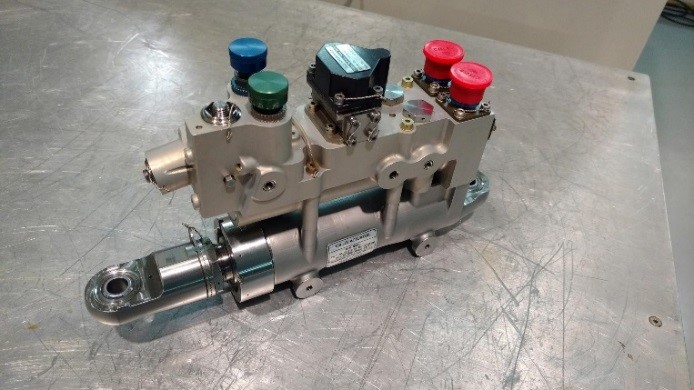

| 1 | LEADING EDGE SLAT ACTUATORS FOR INDIGENOUS LCA PROGRAMME

|

|

| 2 | FACILITY FOR DIFFUSION ALUMINIZATION PROCESS ON ALLOY STEEL SPECIMEN

|

|

| 3 | BATTERY OPERATED HYDRAULIC POWER PACK TO CHARGE LCA BRAKE ACCUMULATOR

|

|

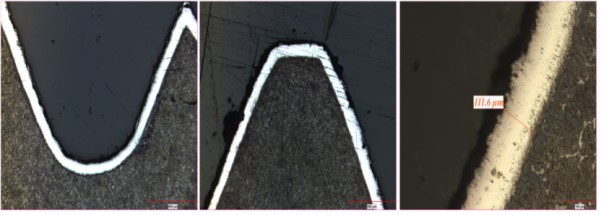

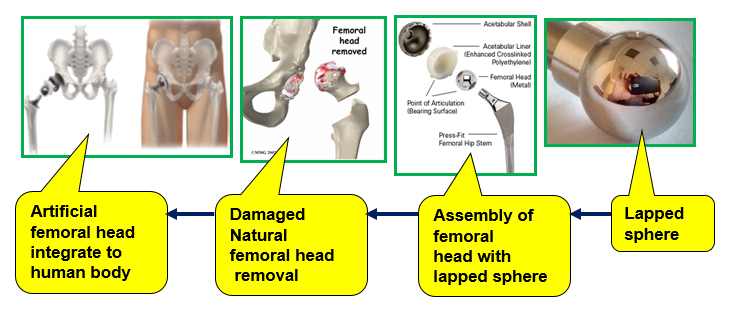

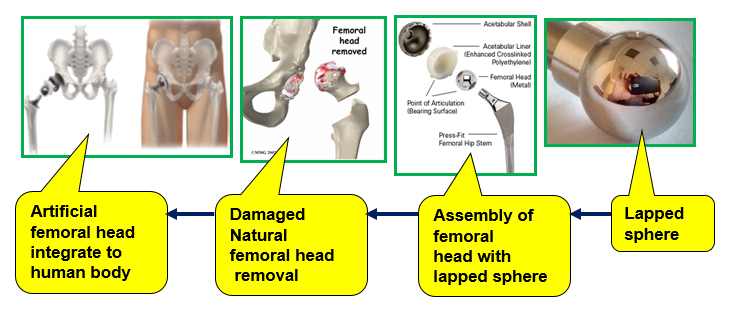

| 4 | DESIGN AND DEVELOPMENT OF SPHERE LAPPING ATTACHMENT

|

|

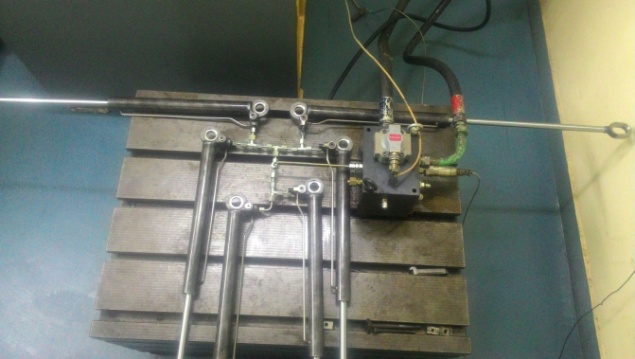

| 5 | QUALIFICATION TESTING OF LEADING EDGE SLAT ACTUATOR Completed Airworthiness qualification testing of LES Actuators with the following tests

|

|

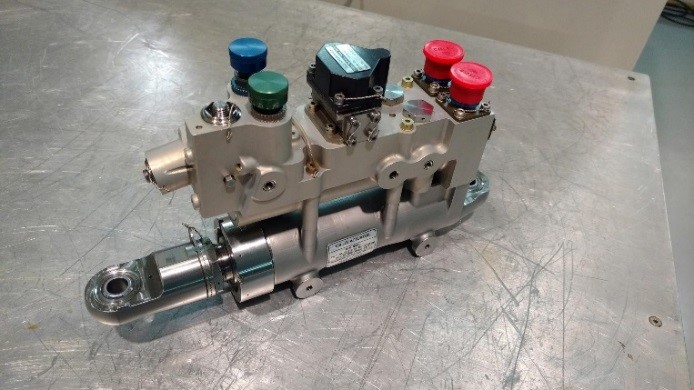

| 6 | Qualification testing of Airbrake actuator servo valve

|

|

| 7 | Development of Endurance Tester for MEMS Pneumatic pressure transducer

|

|

| 8 | Pressure Cycling, Thermal Shock, Proof Pressure And Burst Pressure Test of CCLAH and ACLC

|

|

| 9 | Assembly and Acceptance testing of CTTC filters

|

|

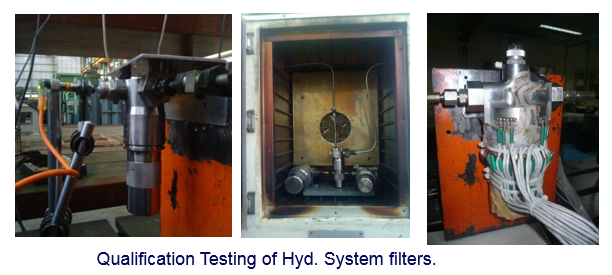

| 10 | Additional Qualification testing of Low pressure and case drain hydraulic system filters

|

|

| 11 | Qualification testing of NRV Dia 25mm and QDC Dia 10mm

|

|

| 12 | Development of Electro-Hydraulic Force Exciter Force Exciter Hydraulic Power supply |

|

| Sl. No. | Name & Specifications | Photo |

|---|---|---|

| 1 | High Speed Shuttleless Rapier Loom (LR-450) |  |

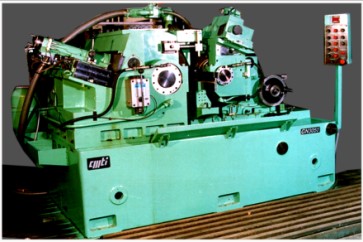

| 2 | Single Head Centreless Bar Turning Machine (TBC – 36) |  |

| 3 | Twin Head Centre-less Bar Turning Machine (TBCDH – 36) |  |

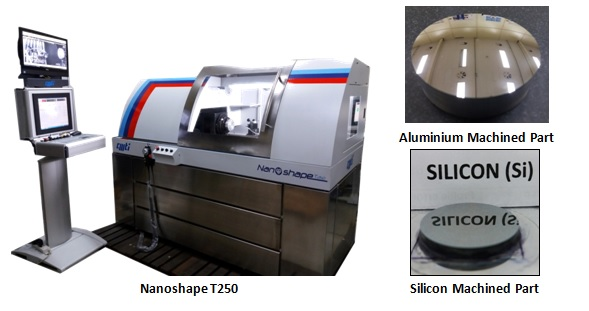

| 4 | Diamond Turning Machine |  |

| 5 | Multi Gauging System |  |

| 6 | Centre less Grinding Machine (GN-3050) |  |

| 7 | Engraving Machine |  |

| 8 | Goliath Facing & Taper Boring Machine |  |

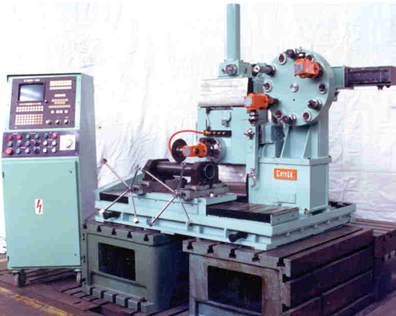

| 9 | CNC Piston Ring Finish Turning and Grooving Machine |  |

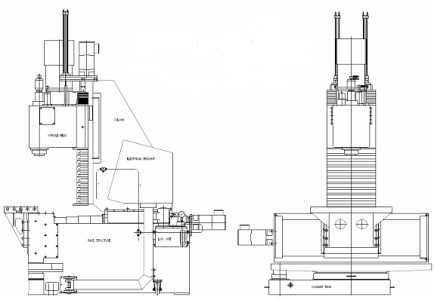

| 10 | Facing and Boring Machine (FB-50) |  |

| 11 | Line Boring Machine (LBM) |  |

| 12 | CNC Keystone Piston Ring Grinding Machine (GKPR-CNC) |  |

| 13 | CNC Vertical Milling Machine |  |

| 14 | CNC Specimen Cutting Machine |  |

| 15 | Universal Cylindrical Grinding Machine (UGC-260) | |

| 16 | VIBRATION MEASUREMENT OF CENTRIFUGAL PUMP AND ENGINE ASSEBLY Initially the vibration measurement was carried out on the engine in decoupled condition to know the existing vibrations, when it is supported on jacks. The abnormal vibrations of the order of 69.3 mm/sec was noticed in this condition and the detailed analysis was carried out and the analysis results depicts, the problem was due to 1.2mm run out in the engine stub shaft. This engine stub shaft run out was resulting into higher unbalance induced vibration. Finally the stub shaft run out problem was corrected. The existing vibration level came down to 20mm/sec. Further analysis was pointing out to lesser structural rigidity of the based frame. The structural rigidity of the base frame was modified by the OEM to increase the stiffness and rigidity of the structure. Finally, the vibration level came down to less than 5mm/sec. |

|

| 17 | NOISE & VIBRATION ANALYSIS & MITIGATION OF MOTOR CYCLES Task: Noise and Vibration Analysis of Motor Cycles by Time Event Analysis, FFT Analysis, 1/3 octave analysis, Order Tracking & waterfall Analysis, Transfer Function Analysis of Motor Cycle Elements to identify the resonant frequencies. All these techniques are used simultaneously to identify improvement areas in the motor cycle. Results: – We identified major improvement points for reduction of noise emitted from the engine for the customer. In the first instance engine noise level was brought down by 8 dBA |

|

| 18 | OPERATOR COMFORT EVALUATION IN AN EARTH MOVING EQUIPMENT Task: The task involved the noise and vibration measurement of load haul dumper used in underground mining. The noise and vibration measurement of the load haul dumper was carried out as per the test conditions mentioned in the standards (ISO2631-1, ISO6394, and SAE J88). Result: – Improved design of seat isolators effected with a better understanding of the customer perception in respect of conflicting requirements arising for vibration isolation and damping during dumping operation and vehicle movement on plain ground. |

|

| 19 | Noise and Vibration Measurement of Transformer Task: This task pertains to the noise and vibration measurement of transformer under full load condition. The vibration acceleration (ref. 1E-05 m/s2) was measured in 1/3rd octave bands (25Hz to 8kHz) at 4 mounts of the transformer, when the transformer was operating under full load condition. The mean vibration acceleration values are compared with the allowable limit values specified by the NES 537. Result: – Improved design of transformer base and selection of appropriate low cost vibration isolators based on the measurement results and to meet the compliance of the standards. |

|

| 20 | Logarithmic Decrement Measurement of Mild Steel Beams Task: The logarithmic decrement & FRF measurements of mild steel solid and riveted beams were carried out in order to find out the natural frequencies & damping coefficient factor of the beams. The measurements were carried out on mild steel beams in cantilever condition. Result: – Improve the of riveting process while joining the two mild steel beams and maintain the equal space between the joints to achieve the good damping value. The higher damping and stiffness values are noticed in composite material. |

|

| 21 | Noise, Vibration and Thermography measurements on Intaglio Printing Machines Task: This task pertains to the Noise, Vibration and Thermography measurements carried out on intaglio printing machines. The measurements were carried out during printing and impression cylinder off condition to assess bearing condition of the plate cylinder and impression cylinder bearings. Result: – Improved the life of bearing of printing drum by measuring the temperature and vibration on the printing drum during maximum printing condition (10000 sheet per Hour). |

|

| 22 | Dynamic Balancing of Ultra Stiff Ultra Precision Turning Machine Task: The task involved dynamic balancing of the USUPTM Spindle assembly. The vibration measurements were carried out on spindle to know the magnitude of unbalance-induced vibration. The vibration severity level was measured in the frequency band of 0-1kHz. Result: – To achieve the surface roughness of less than 1 nanometer, we balancing the spindle to less than G0.4 grade. We achieved the balancing grade less than the G0.1 grade. |

|

| 23 | NOISE SOURCE IDENTIFICATION AND RANKING OF TRACTORS Task: Identification and ranking of different noise sources of Tractor Technique: Measurement of sound intensity over a surface of a complex and multiple noise sources. Result: The investigation led to redesign of engine and transmission element assembly features. Predominant noise source components in the tractor are identified and ranked to help in product development to reduce the noise level further in order to meet the Environmental Norms. |

|

| 24 | SOUND INTENSITY MEASUREMENT OF KOCHI METRO HVAC UNIT Task: The task involved measurement of structure borne noise and sound intensity measurement of Kochi HVAC Unit. The measurement was carried out at different operating condition as per customer requirement and the results are given below. The sound intensity measurement were carried out as per ISO 9614-2, when the VAC Unit running in full cooling mode (all the elements are running) Result: The investigation led to know the maximum noise generated by the HVAC unit element. Predominant noise source components in the HVAC are identified and ranked to help in product development to reduce the noise level further in order to meet the Environmental Norms. |

|

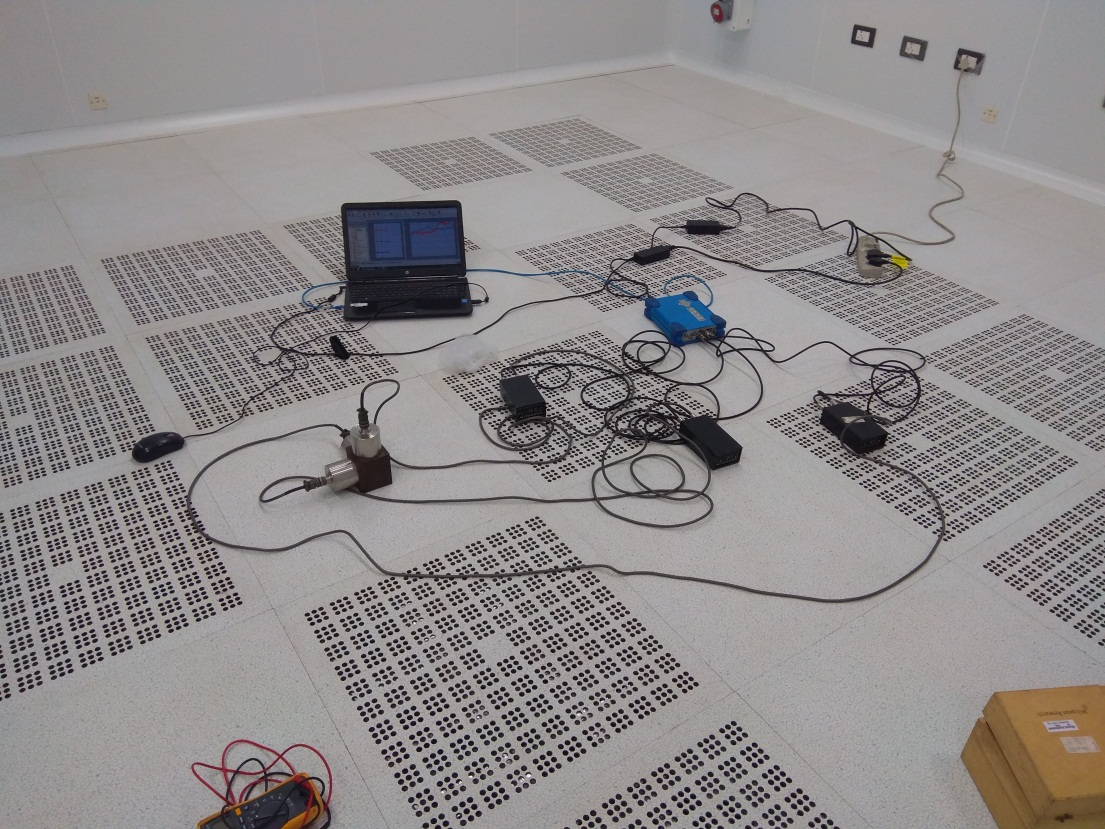

| 25 | GROUND VIBRATION MEASUREMENT AT UNDER GROUND CLEAN ROOM FACILITIES Task: The task involved measurement of ground vibration at inside the underground clean room lab area. The ground vibration due to movement of traffic, men, machine and other environmental activities were measured to know the existing ground vibration levels. Result: The ground vibration measurement values give the selection of isolators for the machined to be installed at the particular area. Before installing any high precision machine like CMM, Diamond Turning and any Metrology equipment we should measure the existing ground vibration levels to select proper isolators |

|

| 26 | STRUCTURE BORNE NOISE MEASUREMENT OF KOCHI METRO Task: The task involved the structure borne noise tests of a HVAC Unit for Kochi Metro. The structure borne noise carried out on the seat supports and handle for passenger support to know the vibration level experienced due to the running of HVAC unit inside the coach. Result: The ground vibration measurement values give the selection of isolators for the machined to be installed at the particular area. Before installing any high precision machine like CMM, Diamond Turning and any Metrology equipment we should measure the existing ground vibration levels to select proper isolators |

|

| 27 | DYNAMIC BALANCING OF PROPELLARS USED IN SUBMARINE Task: Balancing of the propellers was carried out on SCHENCK R2BU Dynamic Balancing Machine. The Propeller was mounted on the mandrel made for the purpose of balancing. The Mandrels were first balanced to a quality grade of better than G0.4 (as per ISO-1940). The propeller was then mounted on the mandrel and balanced to a quality grade of better than G1 grade. Result: The dynamic balancing of propeller to less than G1 grade for the better performance during the application. |

|

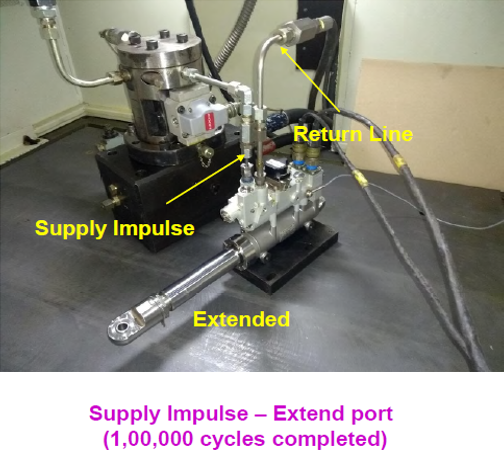

| 28 | Impulse Pressure Test of Retraction Actuator (RA PT-01) for Rustom II – UAV i. Testing as per MIL-PRF-5503F. |

|

| 29 | Performance test on centrifuge for Alfa laval

|

|

| 30 | Pressure Impulse Test on Ti Tubes Pressure impulse testing of indigenous Ti-Tubes as per SAE ARP 1383. |

|

| 31 | Pressure Impulse test on Hydraulic cylinders (Pricol) i. No of Cylinders: 6 nos. |

|

| 32 | LEADING EDGE SLAT ACTUATORS FOR INDIGENOUS LCA PROGRAMME

|

|

| 33 | FACILITY FOR DIFFUSION ALUMINIZATION PROCESS ON ALLOY STEEL SPECIMEN

|

|

| 34 | BATTERY OPERATED HYDRAULIC POWER PACK TO CHARGE LCA BRAKE ACCUMULATOR

|

|

| 35 | DESIGN AND DEVELOPMENT OF SPHERE LAPPING ATTACHMENT

|

|

| 36 | QUALIFICATION TESTING OF LEADING EDGE SLAT ACTUATOR Completed Airworthiness qualification testing of LES Actuators with the following tests

|

|

| 37 | Qualification testing of Airbrake actuator servo valve

|

|

| 38 | Development of Endurance Tester for MEMS Pneumatic pressure transducer

|

|

| 39 | Pressure Cycling, Thermal Shock, Proof Pressure And Burst Pressure Test of CCLAH and ACLC

|

|

| 40 | Assembly and Acceptance testing of CTTC filters

|

|

| 41 | Additional Qualification testing of Low pressure and case drain hydraulic system filters

|

|

| 42 | Qualification testing of NRV Dia 25mm and QDC Dia 10mm

|

|

| 43 | Manufacturing and development of Armature coil Die set |  |

| 44 | Hydraulic Filter components (Aerospace applications) | |

| 45 | Precision Ball Screws (AeroSpace applications) |  |

| 46 | Manufacturing of Turbo blowers and Propellers (Aerospace applications) |  |

| 47 | Agitators |  |

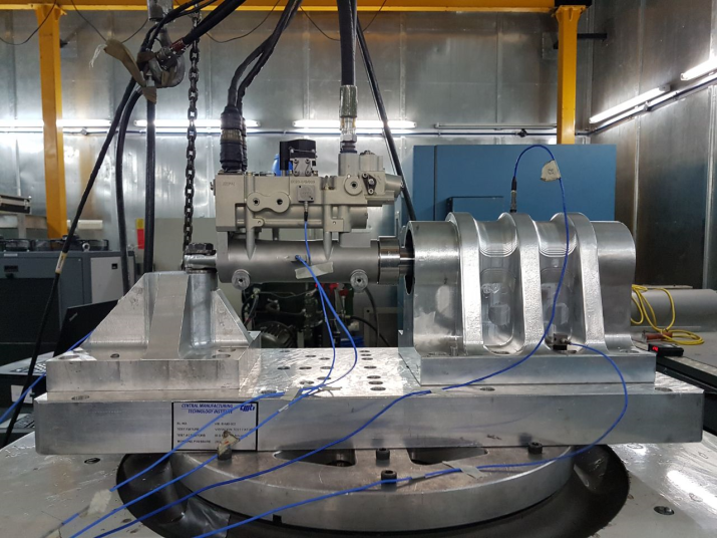

| 48 | Development of Electro-Hydraulic Force Exciter Force Exciter Hydraulic Power supply |

|

Other Misc. Testing

- Onsite performance testing of the centrifugal separator developed by M/s Alfa Laval India Pvt. Ltd, Pune, and M/s GEA Westphalia Separators India Pvt. Ltd., Bangalore.

- Test setup for pressure cycling of the parker filters at 40°C and 80°C, and filter assembly for its fatigue strength test. Pressure cycling tests on hydraulic filters were carried out for 0-8 bar at 5Hz for Parker Hannifin.

- Hot soak and Cold soak of hydraulic cylinders for 24 hrs and performance test on hydraulic cylinders for Wipro Ltd.

- Drum Top Filtration unit was tested by the portable particle counter for its performance for Tri-Millennial Design and Service Engineers Pvt. Ltd.

- Flow Fatigue test of the Hydraulic filters was carried out for 9 bar differential pressure at 1Hz for Micro Precision

- Burst pressure testing of Welded D-Tube and Pressure drop and thermal efficiency test of a cold plate for RangsonsDefense Solution Pvt. Ltd, Bangalore

- Static Pressure testing (pneumatic) of 105 nos. fire extinguisher cylinders of Southern Electronics Pvt. Ltd., Bangalore Pressure drop test and burst pressure testing of Direction control valves, Dynamatic Technologies Ltd, Bangalore

- Performance test on Avionic cold plate was carried out with test fluid, Poly Alfa Olephin (PAO) at 60 °C and flow rate 0.7 GPM for Ranson defence solutions.

- Single-pass performance testing on Filter elements for Gopani Product Systems.

- Filtration efficiency test and dirt holding capacity test on Spin-on filters were taken up and completed for BEML Mysore, Parker Hannifin, Ind Auto filters, Sany Heavy Industries India Pvt. Ltd., Ultrafilter (India) Pvt. Ltd., Micro Precision, Micropore.

- Total no of filters tested for efficiency: 112nos

- Total no of filters tested for pressure cycling: 11nos

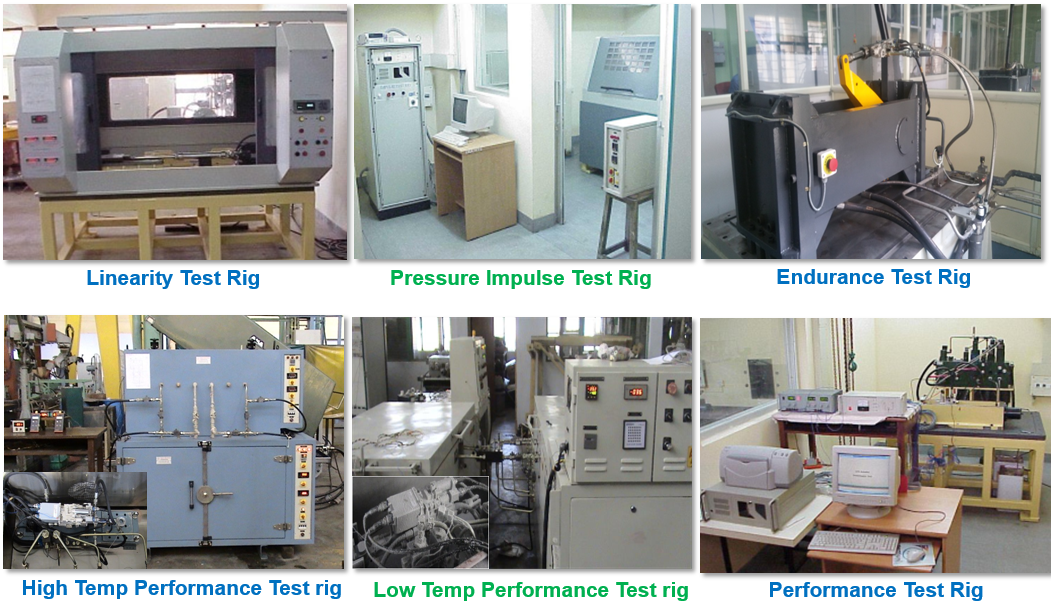

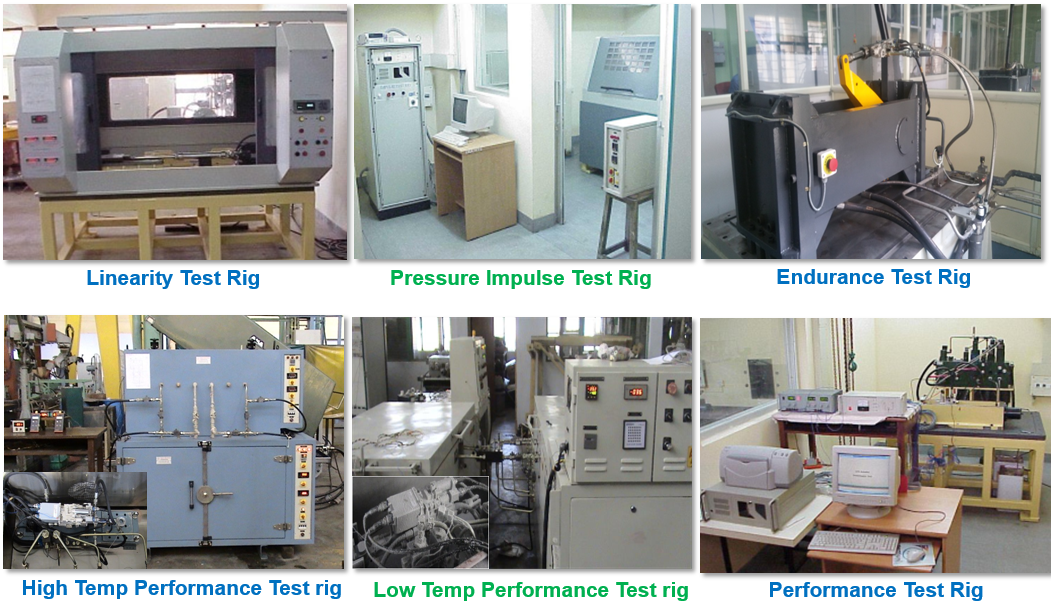

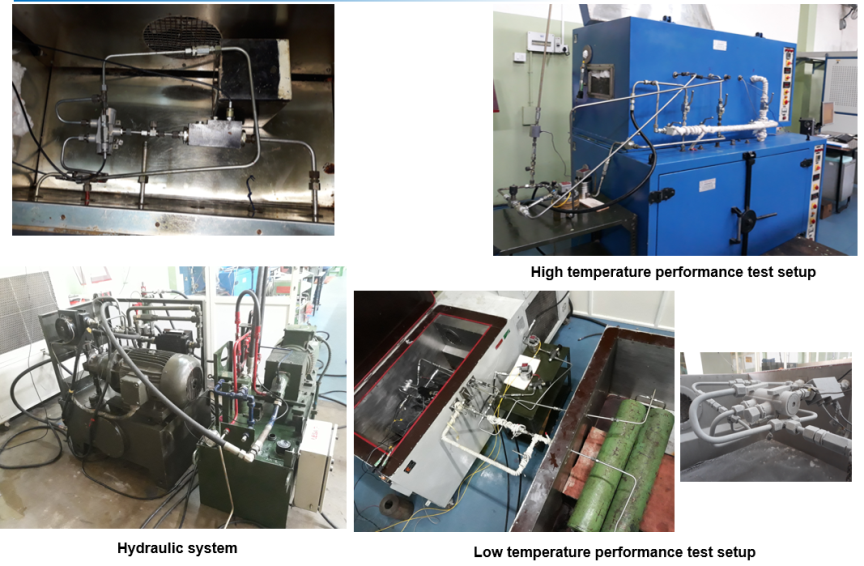

The Hydraulics and pneumatics lab provides testing services in the field of Hydraulics and pneumatics. We undertake specialized activities such as:

- Design and development of LRUs for aerospace applications with focus on pumps, actuators and filters.

- Design & Development of Test Facilities for Qualification Testing of Aerospace Hydraulic Components as per Military Standards

- Qualification Testing of Aerospace Hydraulic Components as per Military Standards

- Consultancy in the field of Fluid Power

Testing services in the field of Industrial Hydraulic Elements.

- Performance Test of Industrial pumps, control valves, cylinders etc

- Thermal Performance test, Endurance test, ageing test, thermal shock test etc.

- Characterization of Industrial hydraulic elements.

- Hydrostatic pressure testing.

- Pressure cycling test on hydraulic elements.

- Cold / hot soak and performance test on hydraulic elements.

- Validation of oil/fuel filter performance by Multi-pass or single pass method, dirt holding capacity, collapse rating etc.

Laboratory services.

- Measurement of oil contamination level by particle count (ISO 4406 & NAS 1638)

- Component cleanliness level checking

- Calibration of Pressure gauges.

- Supply of calibration fluid

- Supply of ultra-clean bottles

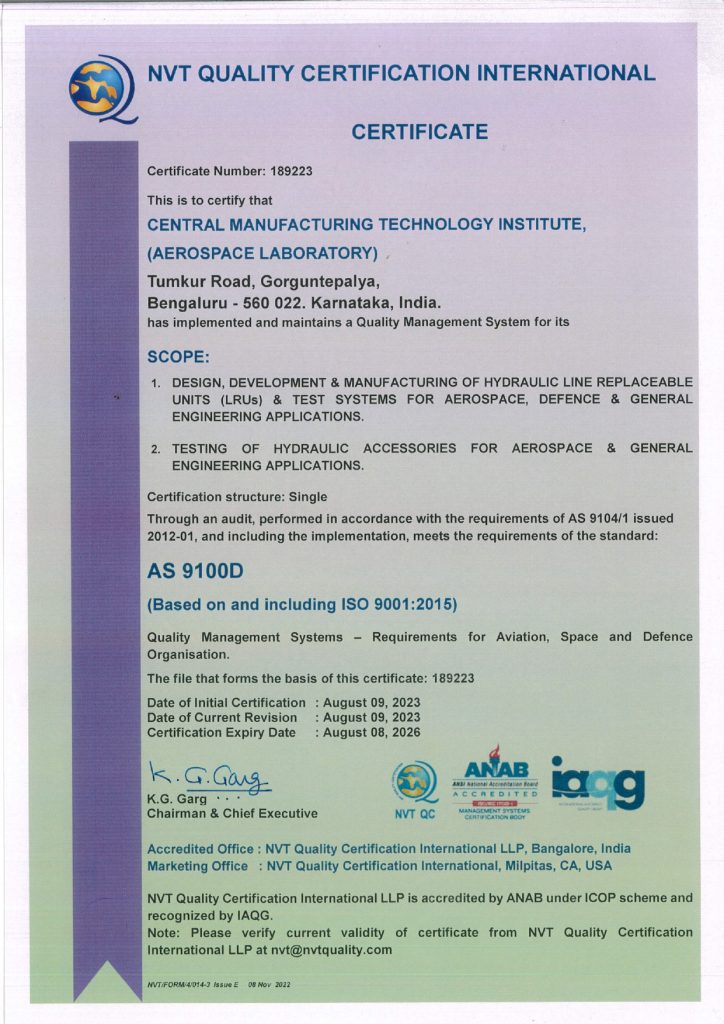

Aerospace test rigs and calibration group is under the purview of C- ASMP with the specific objective of catering to Aerospace design, development and testing requirements. Aerospace Test rigs group targets to augment the Aerospace development arena in India with design and developmental activities of both products and test rigs

Our Core Competencies are

- Design and Development of airworthy products (Actuators, filters and pumps)

- Design & Development of Test Facilities / Test rigs for Qualification Testing of Aerospace Hydraulic Components as per Military Standards.

- Assembly / Qualification Testing of airworthy products as per Military Standards

- Consultancy in the field of Fluid Power

With multi-skilled manpower with experience in multi-domain activities and 30-year experience Aerospace test rig group has catered to a versatile clientele of Aerospace domain.

Facilities include

CAD

- Solidworks 2020 (With simulation premium)

- AutoCAD

20 - Unigraphics UGNX 7.5

FEA

- ANSYS 18.2 (With CFD and HFSS)

DESIGN SOFTWARES

- KISSSOFT and KISSSys2014

MATHEMATICAL MODELLING SOFTWARES

- MATLAB

Rotation speed : 16000 rpm

Operating pressure : 260 bar

Oil temperature layering : up to 125°C

Power : up to 26kW

Test Pump is run under varying operating conditions (Speed, Load, inlet oil temperature) for over 3000 hrs to check its performance.

Mr. Deepak Singh D (Scientist-B)

Email: deepak[at]cmti[dot]res[dot]in

Land Line: +91-80-22188215

Mr. S K Verma(Scientist-F & CH – (C-ASMP) & GH (ES))

Email: vermask[at]cmti[dot]res[dot]in

Land Line: +91-80-22188322

Impulse pressure : 420bar (peak)

Max oil temperature : 135 deg C

Frequency : 1Hz ( for lower pressures and smaller volume requirements, higher frequencies upto 2hz can be tried)

Pressure Increase rate : as per standard (1,00,000psi/sec to 2,00,000psi/sec)

Standard followed : SAE-ARP-1383-2013

Pressure Impulse test setup to determine the ability of the hydraulic component to withstand the repeated pressure pulses within the specified limits. This is an accelerated fatigue test.

Mr. Deepak Singh D (Scientist-B)

Email: deepak[at]cmti[dot]res[dot]in

Land Line: +91-80-22188215

Mr. S K Verma (Scientist-F & CH – (C-ASMP) & GH (ES))

Email: vermask[at]cmti[dot]res[dot]in

Land Line: +91-80-2218832

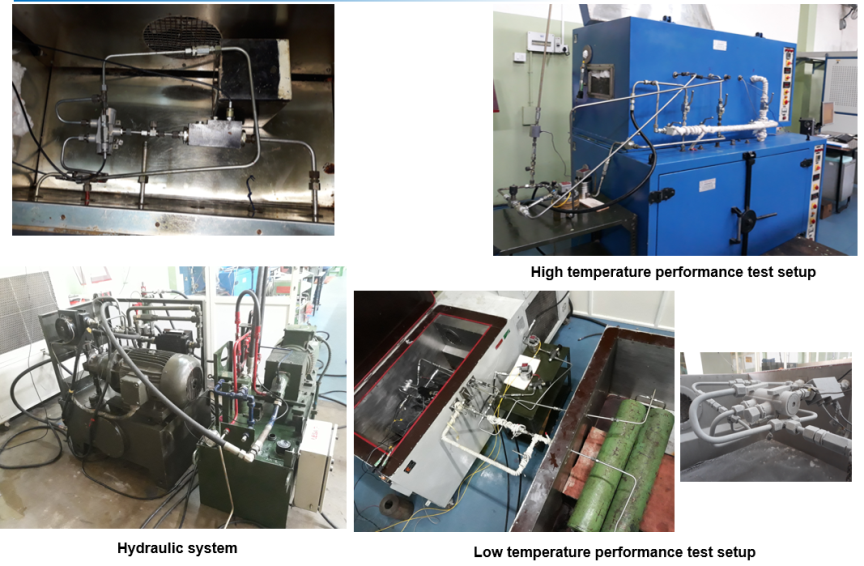

Rotation speed : 16000 rpm

Operating pressure : 260 bar

Oil temperature layering : up to 125°C

Test chamber temperatures

Pump chamber: : Ambient to -60 ˚C

Oil temperature layering :-60˚C to +115 ˚C

- low-temperature soak testing of pump

- low-temperature performance testing of pump

- Thermal shock testing of pump

Mr. Deepak Singh D (Scientist-B)

Email: deepak[at]cmti[dot]res[dot]in

Land Line: +91-80-22188215

Mr. S K Verma(Scientist-F & CH – (C-ASMP) & GH (ES))

Email: vermask[at]cmti[dot]res[dot]in

Land Line: +91-80-22188325

Rotation speed : 16000 rpm

Operating pressure : 260 bar

Oil temperature layering : up to 125°C

Power : up to 26k

- Break-in run test

- Load cycle test

- Response time test

- Calibration test

- Heat rejection test

- Pressure control and stability test

Mr. Deepak Singh D (Scientist-B)

Email: deepak[at]cmti[dot]res[dot]in

Land Line: +91-80-22188215

Mr. S K Verma (Scientist-F & CH – (C-ASMP) & GH (ES))

Email: vermask[at]cmti[dot]res[dot]in

Land Line: +91-80-22188325

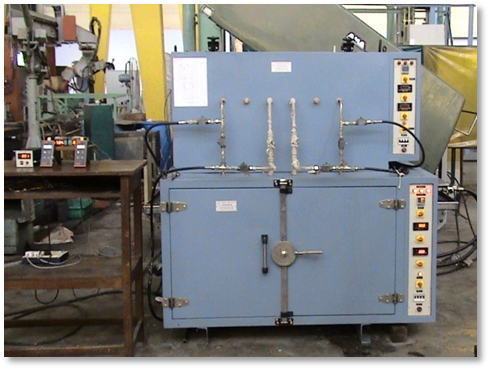

Temperature: Ambient temperature to -50 deg C

Workspace dimension : 1750 x 1000 x 800 mm(max)

- low-temperature soak testing

- low-temperature performance testing

- Low-temperature pressure cycling tests

- Thermal shock testing

Mr. Deepak Singh D (Scientist-B)

Email: deepak[at]cmti[dot]res[dot]in

Land Line: +91-80-22188215

Mr. S K Verma(Scientist-F & CH – (C-ASMP) & GH (ES))

Email: vermask[at]cmti[dot]res[dot]in

Land Line: +91-80-22188325

Temperature : ambient to 200 deg C

Workspace dimension : 1500 x 700 x 800 mm(max)

- High-temperature soak testing

- High-temperature performance testing

- High-temperature pressure cycling tests

- Thermal shock testing

Mr. Deepak Singh D (Scientist-B)

Email: deepak[at]cmti[dot]res[dot]in

Land Line: +91-80-22188215

Mr. S K Verma(Scientist-F & CH – (C-ASMP) & GH (ES))

Email: vermask[at]cmti[dot]res[dot]in

Land Line: +91-80-22188325

PUBLICATIONS

- Tom Thampy, Madhan Kumar. N, D.R Ragavendra, M Maanasan, Karthik Kumar “Design and Development of Electro Hydraulic Force Exciter” FPSI Technical Seminar (FPTS 2016) at Satish Dhawan Auditorium IISC Campus (17th to 18th June. 2016)

- S.Arumugasamy, S.K Verma, & Tom Thampy “Design & Development of Thermal Relief Valve for a Hydraulic Actuator’ FPSI Technical Seminar “Product Design & Manufacturing” at BIEC, Bangalore (10th to 13th Dec. 2008)

- Tom Thampy, Manju M, Prakask VS published a Technical paper on “Pressure Impulse Test at Extreme Temperatures”, FPSI Fluid power magazine

- Tom Thampy, Dattatreya, Sudha L, SachinNaik, Deepak Singh D Investigations on “Pressure Impulse Testing of Hyd. Elements For Air-Worthiness”. FPSI Technical Seminar (FPTS 2018) “Latest trends in Fluid power technology”, 19th & 20th June 2018 at Prof. MRD Auditorium, PES University, Bangalore

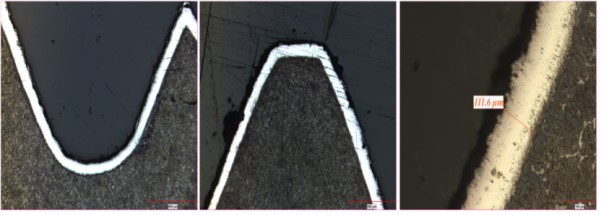

- B. Dattatreya, Anil Kumar K, R. Murali Krishna, V. A. P. Sarma, S. K. Verma, S. Arumugasamy, N. Balashanmugam, (2017), Development of Sphere lapping attachment or CNC Lathe, Manufacturing Technology Today (MTT), Vol.16 (Issue 12):page no 3-6.

- Srivastava E, Anil Kumar K, Design and analysis of Vibration test fixture for 6.2 KW Siemens motor, IJIRSET, Volume 9, Issue 5, May 2020

- Dr. Kavithaa S, Salvin George shaji, and Vijet Bhandiward “Electron beam welding of oxide dispersion strengthened 9 Cr martensitic steel-an experimental and theoretical perspective”, 2nd International Conference on Materials Manufacturing and Modelling, ICMMM – 2019, VIT University, Vellore, 29th - 31st March 2019 [Materials Today: Proceedings, DOI:10.1016/j.matpr.2020.03.379].

Achievements /recognition

- SKOCH Order-of-Merit among Top-30 transformational innovative projects in India and also with the SKOCH Gold Award in Dec 2017 for the innovation in the project “Battery Operated Hydraulic Rig for charging the Parking Brake Accumulator.

- Tom Thampy awarded "IEI Young Engineers Award 2019-20" in Aerospace Engineering Division.

- Tom Thampy, Vinod AR, Sunil magdum received “Innovation award” during MEDIC 2018, for successfully developing and presenting a novel medical device proof of concept as part of team project at Medical device innovation camp (MEDIC-2018) held during 28th Sept. to 2nd Oct 2018 at IIT Bombay, Mumbai.

- Best project award for "Process development of Diffusion Aluminization" during CMTI Foundation Day 2018

Technology development

- Development of Electro hydraulic pneumatic separator for Qualification testing of Pneumatic MEMS pressure sensors for its airworthiness

- Development of Battery Operated Hydraulic Rig for charging of Parking Brake Accumulator of LCA Tejas Aircraft

- Development of test setup for Pressure Impulse Testing of Aircraft hydraulic elements with hydraulic fluid at its elevated temperature +135ºC and -40ºC.

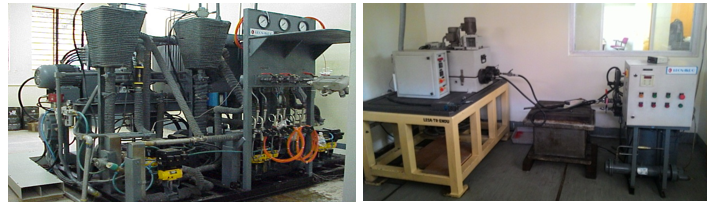

- Development of Electro hydraulic force exciter for modal analysis of machine tool structure.

- Development of Endurance test rig for LES actuator with Electro hydraulic Heating and control of hydraulic oil temperature to continuous supply of hydraulic fluid at 135 ± 2 ºC

- The test setup for pressure cycling of QDC with air as a media for pressure up to 0-15 bar at a frequency 0.5 hz

- Design and development of test setup for various testing as part of its qualification. Test setups were made and tested the indigenously developed hydraulic elements of LCA, Tejas aircraft for its 3000 flying hrs. Different hydraulic elements like actuators, servo valve, hydraulic system filters, up locks, Ti tubes, NRV, QDC, hydraulic release valve, FDCV, Heat exchanger etc tested for its qualification as part of indigenization.

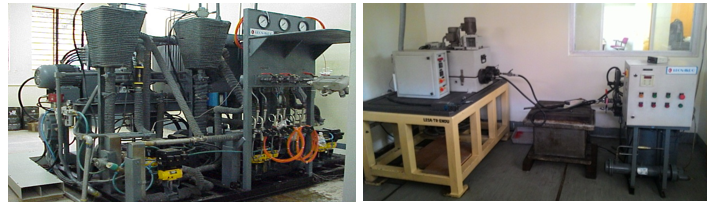

- Development of Universal test rig to test industrial pumps, valves, and hydraulic cylinders in a single test bench.

- Facility for Diffusion aluminization process on Alloy steel specimen

- Development of sphere lapping attachment for mill turn center to achieve spherecity of less than 5μm.

Mr. Shanmugaraj V

Centre Head for Aerospace System Group(AS) and Additive Manufacturing Group(AM)

Phone (Office): +91-80-22188349

Mobile: +91-9449842688

Fax: +91-80-23370428

E-mail: shanmugaraj[at]cmti[dot]res[dot]in