- Introduction

- People

- Research Area

- Projects

- Services

- Facilities

- Achievements

- Gallery

- Contact

India is developing at a mind-boggling pace, with its strategic place as one of the world’s largest economies, it is in dire need of reliance on indigenous technologies.

CMTI’s Centre for additive and special manufacturing (C-ASMP) is a cluster of teams with a specific focus on Prototyping, product and testing technologies which cater to the very need as discussed.

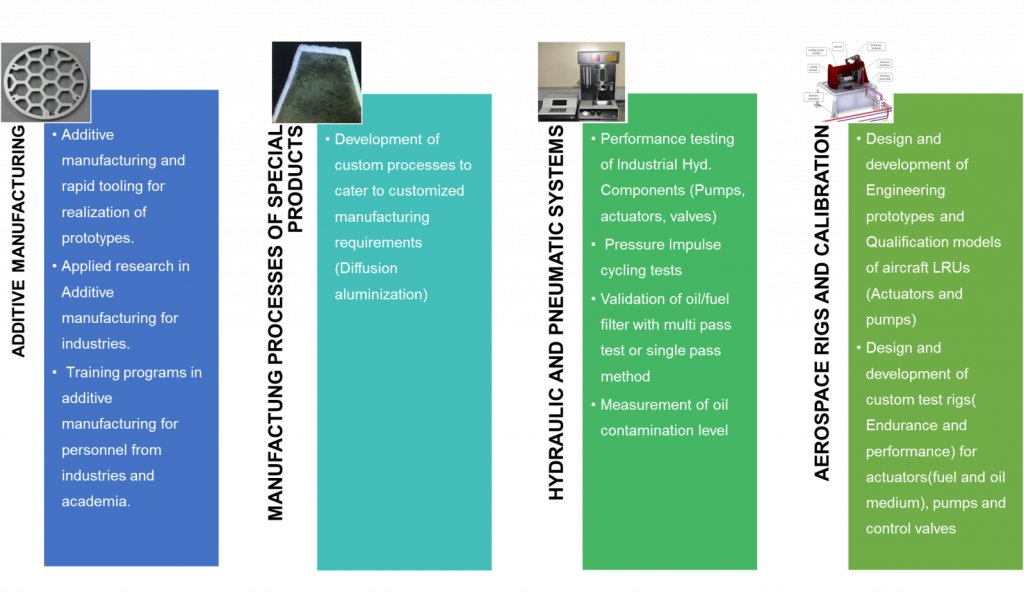

Core Competencies of C-ASMP are,

- Additive manufacturing

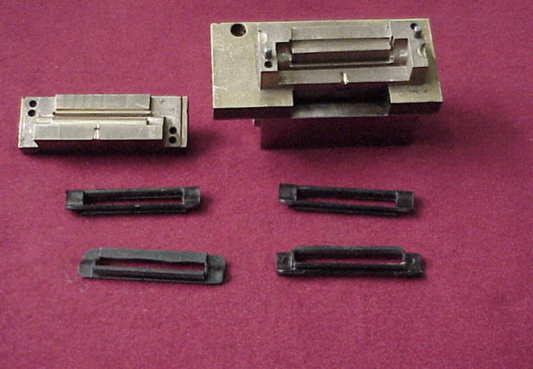

- Manufacturing processes of special products

- Hydraulic and Pneumatic systems

- Aerospace test rig and calibration

| Centre Head | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

|

Mr. Shanmugaraj V | Joint Director | View Profile |

| Group Head | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

|

Mr. Vinod A R | Scientist-D | View Profile |

| Scientists | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

|

Mr. Manjunath B N | Scientist - C | View Profile |

|

Dr. Anusha Epparla | Scientist - C | View Profile |

| Technical Staff | |||

| Photo | Name | Designation | Phone (Office) |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

| Administration | |||

| Photo | Name | Designation | Phone (Office) |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

- Laser material processing using metal Additive Manufacturing

- Remanufacturing / refurbishment

- Bimetallic Parts

- Functionally Graded Materials (FGM)

- Metal Matrix Composites

- Hardfacing / Coatings for wear resistance, corrosion resistance, oxidation resistance, scratch resistance etc.

Completed Projects

- Development of Steel on Aluminium Bronze bimetallic parts by Direct Metal Deposition (DMD) process

- Development of Bronze on Steel bimetallic parts by DMD process

- Development of Steel-Carbon Nano Tube Metal Matrix Composites through Additive Manufacturing

- Laser Sintering of Rare-Earth Metals by Direct Metal Laser Sintering (DMLS) process

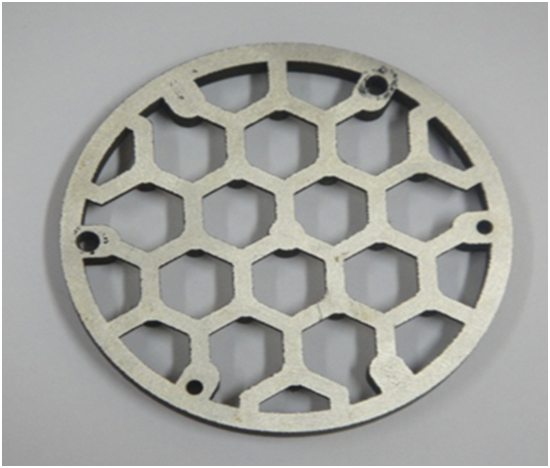

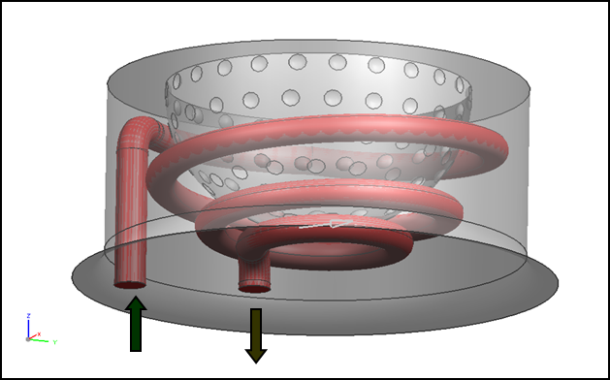

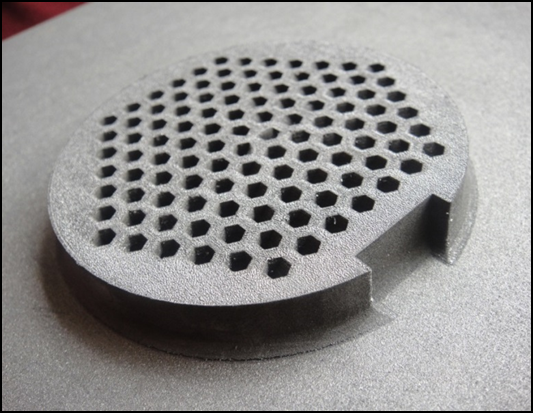

- Fabrication of Honey Comb Heat Exchanger by DMLS

- Synthesis and Characterization of Chromium on Stainless Steel by DMD process

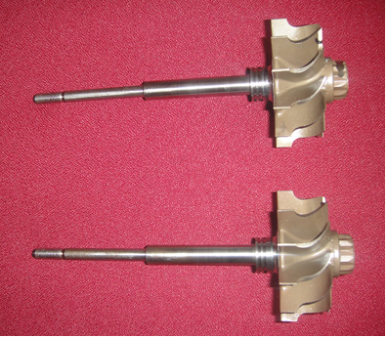

- Research & Development for Remanufacturing of Turbocharger Shaft & Wheel seal groove using Laser Cladding

- Fabrication of Inconel & Inconel-SiC Metal Matrix Composites by AM Process

- Development and Supply of Honey Comb type Orifice by DMLS Technology

- Direct Metal Laser Sintering of Mounting Bracket for Aerospace applications

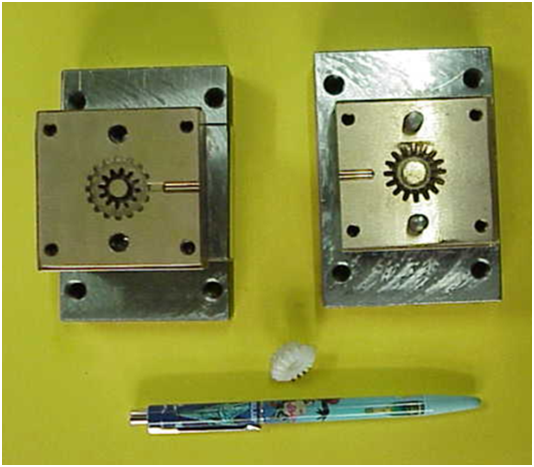

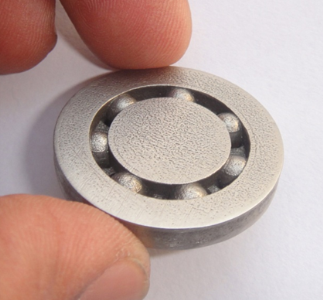

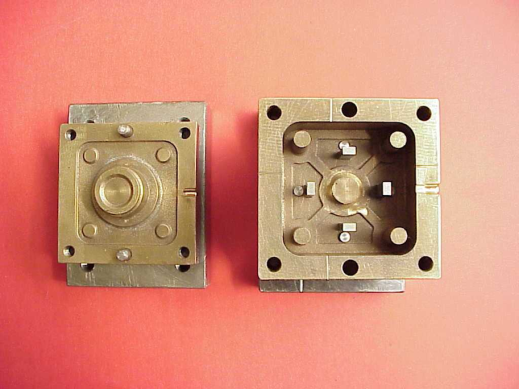

- Fabrication of Ball Bearing Retainer Ring Mould by DMLS

- Laser Sintering of H20 Steel-SiC Metal Matrix Composites by DMLS

- Direct Metal Laser Sintering of EDM Electrodes

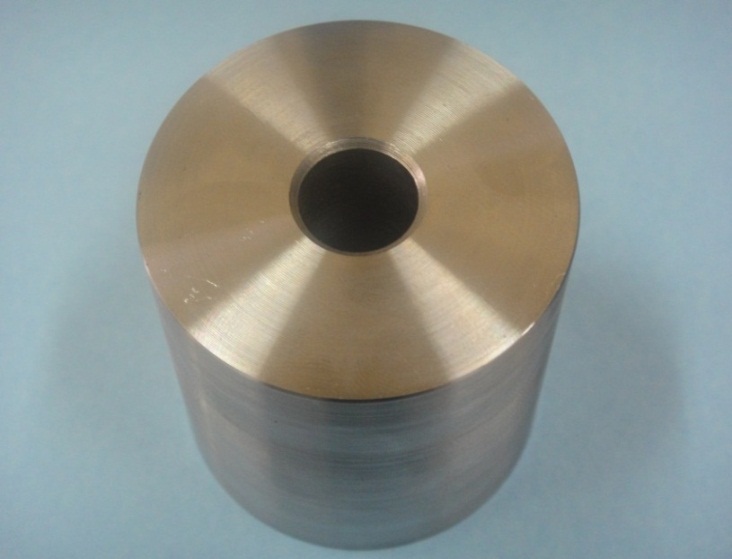

- Development of Technology for Remanufacturing of Oil Pump Drive Shaft by DMD Process for Aerospace applications

- Fabrication of Bronze nickel and Bronze nickel-Graphene test specimens by DMLS process

- Development of Inconel-625 on Stainless Steel bimetallic parts by DMD Process

- Fabrication of Diesel Particulate Filters (DPF) by DMLS process for Automotive applications

- Direct Metal Deposition of Steel-Inconel Functionally Graded Material

- Coating of Colmonoy 5 on Stainless Steel by DMD process

- 3D Printing of SS-316L Parts through DMD process

- Coating of CoNiCrAlY alloy on Stellite by DMD process for Space applications

- 3D Printing of Ni-Ti Shape Memory Alloys through DMD process

- Repair of S45C steel fixtures by DMD process for Automotive applications

On-going Projects

- Development of Hybrid Material Air Sensors through DMD process for Aerospace applications

- Repair of Steel alloy Castings through DED process for Space applications

- DST Funded Project titled “Multi Material Deposition Technology Development for complex geometries of Aircraft Engine Components by Additive Manufacturing”

- SERB Funded Project titled “High strain rate characterization of additive manufactured materials for ballistic loading applications”

- MHI Funded Project titled “Development of Laser-based Directed Energy Deposition Additive Manufacturing Machine”

- SERB Funded Project titled “Multi functional Additive and Ablative Materials Processing via Quasi-Continuous Wave Fiber Laser for Novel Industrial Applications”

- Process development using Additive Manufacturing

- Development of Multi-material parts through Additive Manufacturing

- Remanufacturing of expensive engineering components

- Development of Hardfacing / coatings for improved life and performance of parts by enhancing wear resistance, corrosion resistance, oxidation resistance, scratch resistance etc.

- Development of customized Additive Manufacturing Machines

- Laser : Diode, 1 kW

- Build Size : 300 x 300 x 300 mm

- No. of Axes : 5

- Materials : Tool Steel, Stainless Steel, Inconel, Titanium alloys, Nickel Super alloys, Iron Super alloys etc.

- Remanufacturing

- Multi-material part development – Bimetallic Parts, Functionally Graded Materials (FGM), Metal Matrix Composites etc.

- Hardfacing / Coatings for wear resistance, corrosion resistance, oxidation resistance, scratch resistance etc.

- Near-net shape components

- Adding new features to existing components

Mr. Vinod A R

Group Head for Additive Manufacturing

Centre for Aerospace and Additive Manufacturing (C-ASMP)

Phone (Office): +91-80-22188324

Mobile : +91-9743196855

Fax: +91-80-23370428

Email Id: vinodar[at]cmti[dot]res[dot]in

Mr. Shanmugaraj V

Centre Head for Aerospace and Additive Manufacturing (C-ASMP)

Phone (Office): +91-80-22188349

Mobile: +91-9449842688

Fax: +91-80-23370428

E-mail: shanmugaraj[at]cmti[dot]res[dot]in

Technologies Developed

- Remanufacturing of Turbocharger Shafts for Automotive applications

- Remanufacturing of Oil Pump Drive Shaft for Aerospaceapplications

- Development of Steel on Aluminium Bronze BimetallicParts

- Development of Bronze on Steel Bimetallic Parts

- Development of Inconel on Stainless Steel Bimetallic Parts

- Development of Surface Coating of Colmonoy 5 alloy on Stainless Steel

- Development of Surface coating of CoNiCrAlY alloy on Stellite for Space applications

Publications

- Vinod, A.R., Sameer Warghane, Murugan, A., Balashanmugam, N., Venkaiah, N., “Microstructure and interfacial characteristics of Inconel 625-Ti-6Al-4V bimetallic structure produced by directed energy deposition”, Journal of Materials Engineering and Performance (Published online on 22 May 2023: https://doi.org/10.1007/s11665-023-08250-4)

- Mohsin Khan K, Thella Babu Rao, Manjunath B.N., K. Abhinav, A.R. Vinod, Raffi Mohammed, “Studies on the effect of substrate preheating, interlayer dwell, and heat treatment on microstructure, residual stress, and mechanical properties of IN625 superalloy built by direct metal deposition”, Journal of Engineering Materials and Technology, 2023, Vol. 145, No.4, 041004-1-12.

- Susheel Pandey, Rajeev Srivastava, Rakesh Narain, Vinod, A.R., “Optimization of process parameters for direct energy deposition of 15Cr5Ni precipitation hardened stainless steel for aircraft parts repair and maintenance”, Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2022, Vol.236, No.24., pp. 11505-11520.

- Akash Aggarwal, Sushil Patel, A.R. Vinod, Arvind Kumar, “An integrated Eulerian-Lagrangian-Eulerian investigation of coaxial gas-powder flow and intensified particle-melt interaction in directed energy deposition process”, International Journal of Thermal Sciences, 166 (2021) 106963.

- AkashAggarwal, Arvind Chouhan, Sushil Patel, D.K.Yadav, Arvind Kumar, A.R.Vinod, K.G. Prashanth, N.P.Gurao, “Role of impinging powder particles on melt pool hydrodynamics, thermal behaviour and microstructure in laser-assisted DED process: A particle-scale DEM – CFD – CA approach”, International Journal of Heat and Mass Transfer, 2020, Vol.158, No. 119989, pp.1-19.

- Manjunath, B.N., Vinod, A.R., Abhinav, K., Verma, S.K., Ravi Sankar M., “Optimisation of process parameters for deposition of colmonoy using directed energy deposition process”, Materials Today: Proceedings, Vol. 26, Part 2, 2020, pp. 1108-1112.

- Manjunath, B.N., Vinod, A.R., Verma, S.K., Balashanmugam, N., “Challenges and research opportunities in metal additive manufacturing”, Manufacturing Technology Today, 2019, Vol. 18, No. 3, pp. 54-57.

- Manjunath, B.N., Prafullakumar Chaudhari, Hemant Pawar, Verma, S.K., Anasane, S.S., "Review on design guidelines for selective laser melting", Manufacturing Technology Today, 2019, Vol. 18, No. SP 3, pp. 10-18.

- Mahanthesha, P., Mohankumar, G.C., Vinod, A,R., “Microstructure evaluation of direct metal laser sintered SS316L – MWCNT composite”, Manufacturing Technology Today, 2017, Vol. 16, No. 8, pp. 3-9.

- Vinod, A.R., Srinivasa, C.K., Shashikumar, P.V., Keshavamurthy, R., “A Novel technique for reducing lead-time and energy consumption in fabrication of Inconel-625 parts by Laser-based metal deposition Process”, Rapid Prototyping Journal, 2016, Vol. 22, No. 2, pp. 269 – 280.

- Sateesh, N.H., Mohankumar, G.C., Krishna, P., Srinivasa, C.K., Vinod, A.R., “Microstructure and mechanical characterization of laser sintered inconel-625 superalloy”, Procedia Materials Science, 2014, Vol. 5, pp. 772 – 779.

- Vinod, A.R., Srinivasa, C.K., Keshavamurthy, R., Shashikumar, P.V., “Deposition of bronze-nickel on steel by laser-based metal deposition process”, Manufacturing Technology Today Journal, 2014, Vol.13, No.1, pp. 27-30.

- Vinod, A.R. and Srinivasa, C.K., “Studies on laser-sintering of copper by direct metal laser sintering process”, 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), IIT Guwahati, Assam, 2014, pp. 377-1 to 377-4.

- Mahanthesha, P., Srinivasa, C.K., Mohan Kumar, G.C., “Processing and characterization of carbon nanotubes decorated with pure electroless nickel and their magnetic properties”, International Conference on Advances in Manufacturing and Materials Engineering (ICAMME-2014), NITK Surathkal, 2014.

- Keshavamurthy, R., Padmanav Rashmirathi, Vinod, A.R., Srinivasa, C.K., Shashikumar, P.V., “Optimization of process parameters for direct metal deposition of H13 tool steel”, International Journal of Advanced Materials Manufacturing & Characterization, 2013, Vol. 3, No. 2, pp. 515-519.

- Srinivasa, C.K., Vinod, A.R., Shashikumar, P.V., “Machinability studies on laser-sintered iron-silicon carbide metal matrix composites using wire electrical discharge machining”, International Journal of Materials and Product Technology, 2012, Vol. 43, No. 1/2/3/4, pp. 68-83.

- Mahanthesha, P., Srinivasa, C.K., Shashikumar, P.V., Mohan Kumar, G.C., “Characterization of carbon nanotubes”, In: Basu, S.K., Ahuja, B.B., Chikate, P.P., (Eds), Proceedings of 7th International Conference on Precision, Meso, Micro and Nano Engineering COPEN-7, College of Engineering, Pune, 2011, pp. 340-343.

- Vinod, A.R., Srinivasa, C.K., Shashikumar, P.V., “Effect of fillet radius on the warpage of parts produced by DMLS”, In: Satyanarayana, B., and Ramji, K., (Eds), Proceedings of 3rd International and 24th National AIMTDR Conference, Andhra University, Visakhapatnam, 2010, pp. 119-122.

- Srinivasa, C.K., Ramesh, C.S., Shashikumar, P.V., “Mechanical properties of iron-SiC composites produced by DMLS process”, In: Satyanarayana, B., and Ramji, K., (Eds), Proceedings of 3rd International and 24th National AIMTDR Conference, Andhra University, Visakhapatnam, 2010, pp. 259-261.

- Vinod, A.R., Srinivasa, C.K., Shashikumar, P.V., “Geometrical and dimensional accuracy of parts built by DMLS process”, International Conference on Advanced Materials, Manufacturing, Management and Thermal Sciences, Siddaganga Institute of Technology, Tumkur, 2010, MF-32.

- Srinivasa, C.K., Ramesh, C.S., Prabhakara, S.K., “Blending of iron and silicon carbide powders for producing metal matrix composites by laser sintering process”, Rapid Prototyping Journal, 2010, Vol. 16, No. 4, pp. 258-267.

- Srinivas, C.K., Ramesh, C.S., Avadhani, S.S., Prabhakar, S.K., “Corrosion behavior of iron and iron-SiC composites produced by DMLS process”, Manufacturing Technology Today Journal, 2010, Vol. 8, No. 9, pp. 3-7.

- Ramesh, C.S., Srinivas, C.K., Raju, V.R., Keshavamurthy, R., “A study on surface finish of laser-sintered iron-SiC composites”, STLE Conference, Las Vegas, USA, 2010.

- Ramesh, C.S., Srinivasa, C.K., “Friction and wear behavior of laser-sintered iron–silicon carbide composites”, J. Mater. Process. Technol., 2009, Vol. 209, No. 14, pp. 5429-5436.

- Ramesh, C.S., Srinivasa, C.K., Channabasappa, B.H., “Abrasive wear behaviour of laser sintered iron–SiC composites”, Wear, 2009, Vol. 267, No. 11, pp. 1777-1783.

- Ramesh, C.S., Srinivasa, C.K., Channabasappa, B.H., Keshavamurthy, R., “Abrasive wear behavior of laser sintered iron-SiC composites”, In: 1st International Conference on Abrasive Processes (ICAP 2008), Churchill College, Cambridge, U.K., September, 2008, pp. 21-25.

- Ramesh, C.S., Srinivasa, C.K., Srinivas, K., “Friction and wear behaviour of rapid prototype parts by direct metal laser sintering”, Tribology - Materials, Surfaces & Interfaces, 2007, Vol. 1, No. 2, pp. 73-79.

- Ramesh, C.S., Srinivasa, C.K., Avadani, S.S., Channabasappa, B.H., “Electroless nickel plating on silicon carbide particles for MMC applications”, In: Kori, S.A., Claude, E., Mahadevappa, G., (Eds.), Proceedings of International Symposium on Advanced Materials and Processing (ISAMP), Bagalkot, India, 2007, pp. 150–154.

- Srinivasa, C.K., Ramesh, C.S., Prasad, S.V., An overview of rapid prototyping processes, Manufacturing Technology Today, 2006, Vol. 5, No. 6, pp. 26-29.

- Srinivasa, C.K., Ramesh, C.S., Somashekar, B.S., “Sintering processes in production of industrial components”, In: Proceedings of the National Conference on Emerging Trends in Mechanical Engineering (NCETM), BMS College of Engineering, Bangalore, (ETIME), 2006, pp. 23–25.

- Gajendran, C., Srinivasa, C.K., Gurumurthy, T., Murthy, J.R.K., “Application of direct metal laser sintering (DMLS) RP technology for injection moulding and investment cast tooling”, In: Proceedings of National Conference on Investment Casting (NCIC), Durgapur, India, 2003, pp. 137-142.

- Ramesh, C.S., Srinivasa, C.K., “Friction and wear behavior of laser-sintered iron–silicon carbide composites”, J. Mater. Process. Technol., 2009, Vol. 209, No. 14, pp. 5429-5436.

- Ramesh, C.S., Srinivasa, C.K., Channabasappa, B.H., “Abrasive wear behaviour of laser sintered iron–SiC composites”, Wear, 2009, Vol. 267, No. 11, pp. 1777-1783.

- Ramesh, C.S., Srinivasa, C.K., Channabasappa, B.H., Keshavamurthy, R., “Abrasive wear behavior of laser sintered iron-SiC composites”, In: 1st International Conference on Abrasive Processes (ICAP 2008), Churchill College, Cambridge, U.K., September, 2008, pp. 21-25.

- Ramesh, C.S., Srinivasa, C.K., Srinivas, K., “Friction and wear behaviour of rapid prototype parts by direct metal laser sintering”, Tribology - Materials, Surfaces & Interfaces, 2007, Vol. 1, No. 2, pp. 73-79.

- Ramesh, C.S., Srinivasa, C.K., Avadani, S.S., Channabasappa, B.H., “Electroless nickel plating on silicon carbide particles for MMC applications”, In: Kori, S.A., Claude, E., Mahadevappa, G., (Eds.), Proceedings of International Symposium on Advanced Materials and Processing (ISAMP), Bagalkot, India, 2007, pp. 150–154.

- Srinivasa, C.K., Ramesh, C.S., Prasad, S.V., An overview of rapid prototyping processes, Manufacturing Technology Today, 2006, Vol. 5, No. 6, pp. 26-29.

- Srinivasa, C.K., Ramesh, C.S., Somashekar, B.S., “Sintering processes in production of industrial components”, In: Proceedings of the National Conference on Emerging Trends in Mechanical Engineering (NCETM), BMS College of Engineering, Bangalore, (ETIME), 2006, pp. 23–25.

- Gajendran, C., Srinivasa, C.K., Gurumurthy, T., Murthy, J.R.K., “Application of direct metal laser sintering (DMLS) RP technology for injection moulding and investment cast tooling”, In: Proceedings of National Conference on Investment Casting (NCIC), Durgapur, India, 2003, pp. 137-142.

Mr. Shanmugaraj V

Centre Head for Aerospace and Additive Manufacturing (C-ASMP)

Phone (Office): +91-80-22188349

Mobile: +91-9449842688

Fax: +91-80-23370428

E-mail: shanmugaraj[at]cmti[dot]res[dot]in

Mr. Vinod A R

Group Head for Additive Manufacturing

Centre for Aerospace and Additive Manufacturing (C-ASMP)

Phone (Office): +91-80-22188324

Mobile : +91-9743196855

Fax: +91-80-23370428

Email Id: vinodar[at]cmti[dot]res[dot]in