- Facilities

- Project

- Temperature Range: -40 to 1850C

- Humidity Range: 10 to 95% Rh

- Chamber Volume: 50 Lts

- Sample Load Capacity: 20 Kg

- Access Port: 4 inch opening with Silicone cork

- Temperature Range: -40 to 1850C

- Humidity Range: 10 to 95% Rh

- Chamber Volume: 50 Lts

- Sample Load Capacity: 20 Kg

- Access Port: 4 inch opening with Silicone cork

- Geometric Magnification = 2000x

- Can be detect down to 500nm

- Non destructive test of MEMS Packages

- Inspection of defects in Dies, Wafers

- Inspection of PCB defects and casting parts

- Smallest detectable leak rate of 5 x 10-12 mbar l/s.

- Automatic calibration of leak detector with standard fine leak (NIST certified)

- Fine leak inspection of hermetic sealing and qualification of seal.

- Bombing and vacuum inspection of sealed device, to qualify for MIL-STD-883 method 1014 for military and aero space applications.

- Sniffer inspection for fine leak detection

- Pull, push (10 kgf) and shear tests (100 kgf)

- Supports 80x magnification and fine pitch analysis

- Mechanical characterization of die attach process

- Mechanical characterization of wire bonding process

- 6” wafer inspection

- High resolution Micromanipulators – XYZ resolutions ≥ 80TPI

- Electrical inspection of 6” wafer – KGD and quality inspection

- Failure analysis of devices

- Probing of I/O pads on devices from Front End Of Line (FEOL) and Mid End Of Line (MEOL)

- Various reflected light options like Bright field, dark field, Polarization, Differential Interference Contrast (DIC) and Fluorescence.

- Transmitted light options like bright field and polarization for inspection of transparent specimen like glass and certain polymers

- Inspection, process control and defect analysis in MEMS packaging process

- Structural analysis of materials

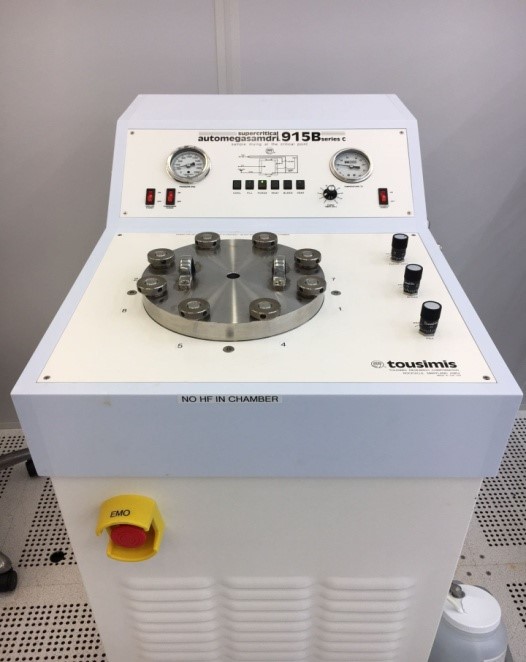

- Liquid CO2 based

- Suitable for wafer sizes upto 6” and small dies.

- Drying of MEMS released structures.

- Drying of high aspect ratio micro structures.Sample preparation for SEM

- 6kW, 60kV electron beam gun.

- Twin gun configuration with horizontal gun to avoid sagging of long cylindrical jobs during welding

- Vacuum hermetic sealing of microelectronic components.

- Military and aerospace applications where reliability of the system is important, Hermetic sealed micro electronics is essential.

- Micro joining and macro joining of dissimilar materials

- Resistive welding of different package size ranges from 3mm to 150mm.

- Multiple packages seam sealing in one fixture

- N2 based hermetic seam sealing of micro electronics.

- Military and aerospace applications where reliability of the system is important, Hermetic sealed micro electronics is essential

- Semi-automatic wire bonder

- Performs Ball-wedge, wedge-wedge and deep access bonding

- Capable of Copper bonding

- Au, Al, Cu wire bonding for MEMS

- Gold ball bumping

- Copper bonding

- Wafer bonding of two or more wafers of size

- upto 6” and small dies.

- Suitable for Thermo-compression, Anodic,

- Fusion, Glass frit and Adhesive bonding

- Bonding force: upto 20 kN

- Temperature: upto 500°C with ± 2%

- Uniformity

- Manufacturing of MEMS sensors

- Wafer level Packaging of MEMS sensors

- 3D packaging of MEMS+ASIC

-

- Thermo compression, reflow, eutectic, epoxy and Thermo sonic bonding capability

- Formic acid vapor tool configuration

- Autocollimator & Advanced Laser leveling system

- Fragile material compatibility

- Temperature up to 450 degree C

- Force range up to 100 kg

- Fine pitch bonding of 15 µm achieved

- Multi chip modules

- Wireless multi stack chip bonding

- Sub-merged dicing for released structures

- Can dice 6 inch wafer

- Dicing of released MEMS sensors

- Dicing of wafers and smaller dies

- Programmable process control 0 to 300 W,

- wide range RF power supply

- Surface preparation for wire bonding and die attach process

- Contamination removal in the MEMS packaging process

- NPP and SS perforated top with Laminar flow

- Cleaning of Wafers/ die/ samples using different process.

- Etching of different materials.

- Photo-resist coating and its development

- Wafer cleaning and chemical processing

- 10 kW and 6 kW Twin gun configuration for co-evaporation.

- Chamber vacuum of up to 3×10-7 mbar

- Suitable for single wafer handling up to 6“

- Equipped with a grid less ion source and effusion cell

- Load lock and variable source to substrate distance from 500-700 mm

- Substrate heating up to 600 oC and max 30 rpm substrate rotation

- Intermediate metal layer deposition in 3D packaging

- Optical coatings

- Insulating dielectrics deposition in fabrication and stacking approach

- 6″ Wafer Processing

- Manual Wafer Loading, Automated Robot Transfer To Load-lock Chamber

- ESC With Active Wafer Temperature Control (Helium Backside Cooling)

- High-speed Gas Line System For Improved Response And Smoother Sidewalls

- Notch Prevention Package For SOI Applications

- TSV formation for Advanced Micro-system Packaging

- High Aspect Ratio Micro-structures

- Electroplating Station designed for MEMS/NANO and High density Interconnects.

- Dedicated Cu & Gold Plating Tanks. Suitable

to deposit any metal or alloy from aqueous solution. - Suitable for deposition on small sized dies (20mm X 20mm) and wafers upto 6″ Wafers

- Deposition Uniformity :>5% across the wafer

- Gold, Copper Electroplating for MEMS devices

- Electrodes metallization

- Individually temperature controlled heaters with max 450oC.

- 20 KN force achieved with high degree of uniformity of pressure distribution.

- Pattern size up to 50nm

- Polymer Micro needle array

- Polymer Micro fluidic channel

- Polymer Micro lens array

- Wafer thickness ranging from 0.1 to 10mm can be handled upto to 6″ diameter.

- Can achieve feature size up to 50nm.

- Polymer Micro Optics

- Polymer Micro fluidic channel

- Polymer Micro lens array

- Wafer handling capacity: upto 6 inch

- Spin coating of Photo resists, Polymers, Anti sticking coatings (ASL), Adhesives, Promoters

- Handles wafers upto 6 inch

- Alignment accuracy = ± 1µm

- Performs bond alignment

- photolithography for fabrication of MEMS devices

- Master mold creation for Nano Imprint Lithography

1. Development of 3D Scanning Technologies by Digital Fringe Projection and Laser Scanning technologies

CMTI has experience in developing 3D scanners working on Digital Fringe Projection (DFP) and laser scanning technologies. The fringe projection based scanning technology is able to 3D scan the components to an accuracy of 30 µm. It is a tripod mounted scanner with various options for view combining like marker based, optical tracker (Developed by CMTI) based, robot mounted etc. The laser based scanner developed in-house is designed for hand-held laser scanning. The device is capable of 3D scanning of intricate features by easily manoeuvring the device over the object and is suitable for dark components scanning. These 3D scanners generate 3D model of a given component which is used in applications like 3D measurements, design evaluation, reverse engineering etc. 3D measurement technologies are highly in demand from industries and in various application domains.

-

Trikon-2 Hand-Held Laser Scanner

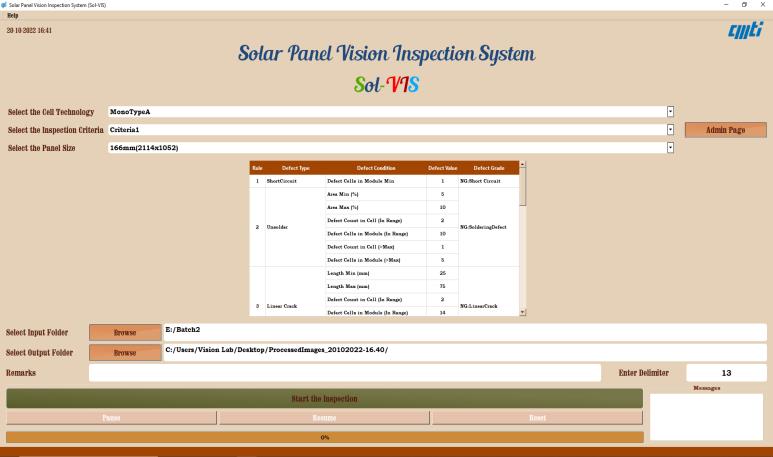

2. SolVIS: The AI Based Solar Panel Inspection Software

SolVIS is an inspection software for carrying out automated quality check on pre-captured EL images of onocrystallineand polycrystalline solar panel thereby providing characterization, reducing human error and stress and increasing efficiency of inspection.

Following are the distinctive features of the system:

- Defect detection and location marking.

- Defect characterization based on length and area.

- User defined dynamic inspection criteria.

- Inspection report with detailed defect statistics.

- Cycle time of 4 Secs/ panel.

- Option to train new panels.

3. Thread measurement system

- Non-contact and improved method of external thread form parameter measurement to check for dimensional tolerances.

- High speed thread parameter measurement system which can be used for automating the thread measurement process in the thread manufacturing lines.

- User friendly thread measurement system requiring minimum human intervention.

- Records measurement results for statistical analysis.

3. Fluted Roller Vision Inspection system for defects.

- The system is a vision based inspection system designed to inspect the fluted roller, used in textile machinery, for presence of chip-out and damages at before plating stage.

- The fluted roller vision inspection system consists of two sets of inspection units each unit consisting of a machine vision camera, optics and light sources.

- There are 8 variants in this component with variations in roller length, roller diameter, flute length and flute pitch.

- Various challenges like presence of oil on surface of the sample, reflective surface and variations in sizes and appearance are addressed in this project.

- The software has features like auto inspection cycle, manual inspection cycle, excel reporting eature, summary analysis report, model type detection, wrong loading detection in addition to the defect inspection feature.

4. Optical Tool Setter for USUPTM

- Optical tool setter is an accessory developed for performing the initial tool setting operation in the ultra precision turning machine, developed by CMTI. The system significantly reduce the tool setting time and also simplifies the process by providing accurate measurements of the tool tip offset and the tool nose radius.

5. Automated inspection of surgical screw

- The system is a non-contact inspection solution using machine

vision for Surgical Screws or Bone Screws. The inspection involves critical

dimensional measurement with very high accuracy for various parameters to be

inspected with different sizes and types of screws.

6. Automated inspection of drippers

- The system is a non-contact system for inspection of drippers.

Drippers are used in irrigation system. Different types of defects like hole blockage, flash on root and collar, cut on collar, short moulding and circularity of the drippers are inspected in this system.

7. Automated inspection of retaining bush.

- “Retaining bush” is a safety critical automotive plastic injection mould component.

- Able to identify all types of defects encountered in the component an inspection stations with 2 cameras

- Inspection rate of 3 components / sec

- Inspection also includes key dimensional measurements

- Automated Component feeding using a vibratory feeder.