- Introduction

- Services

- Facilities

- Contact Us

- Gallery

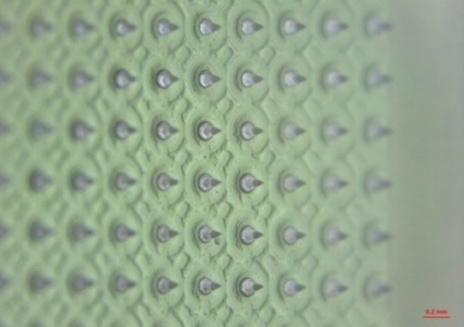

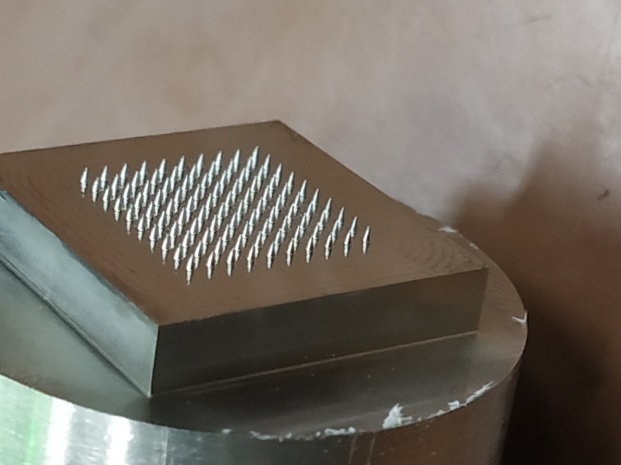

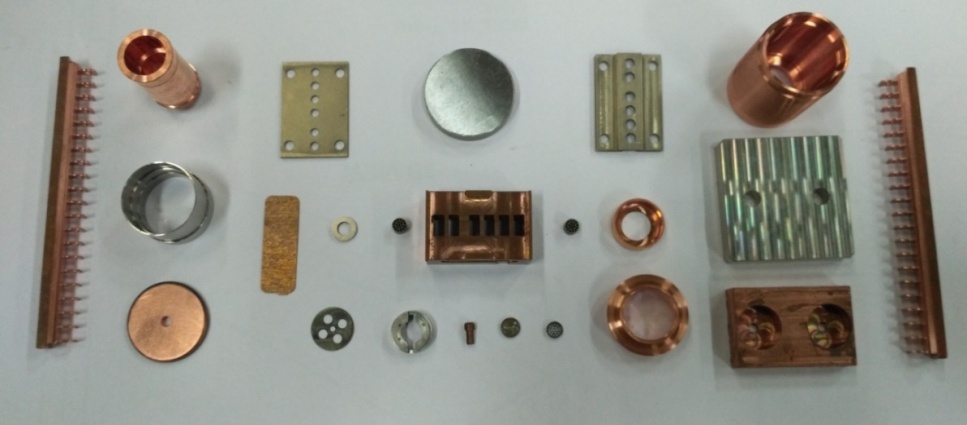

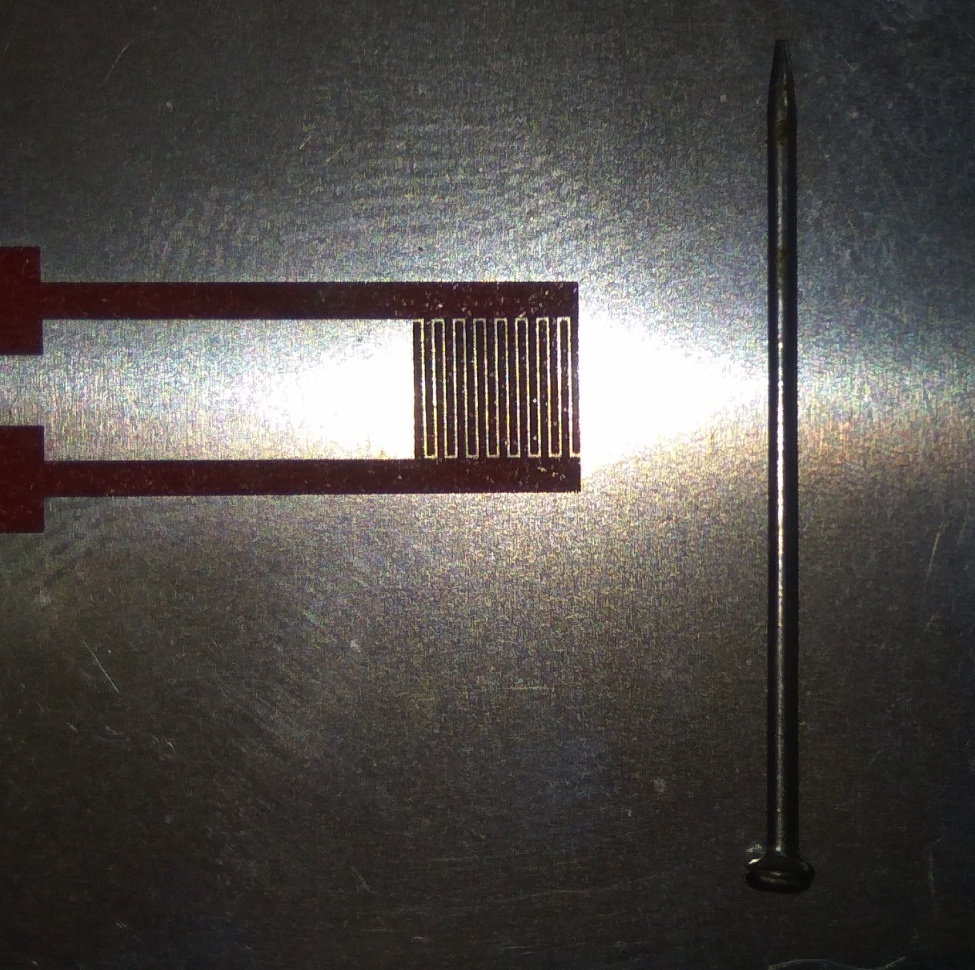

Micromachining facility at CMTI with its state of the art infrastructure and expertise promotes the benefit of micromachining and ultra-precision technology for manufacture of micro-components to the Indian industries through consultancy, services and training. Precision Manufacturing & Process Engineering group focuses particularly in development of products indigenisation and fabrication services of high precision parts.

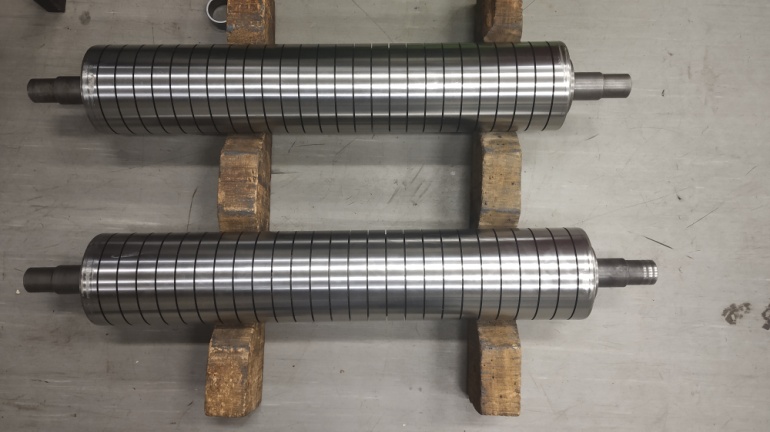

PMPE group has executed many service projects towards development of micro components indigenously. Developed high precision components for Aerospace, Defence, Biomedical and Automobile parts that require precision manufacturing technologies comprising micro feature sizes and dimensional tolerances less than 5µm.Micro components and features ranging from 5 microns to 2-3 mm and dimensional accuracies from 1 micron to 10 microns have been developed for many applications for the components like micro needles, micro channels, micro fuel injection parts, sensors, biomedical parts etc,. Components like Hyperbolic Feed Rollers for automobile industries, breathing regulators components having low feature sizes and 100% quality acceptance criterion for bio medical application, fuel injector components and gyroscopic flexural components for aerospace industries are being manufactured and supplied to the user industries.

Service Charges

|

SL. No. |

Facility |

Industry (Charges in Rs/Hour) |

Academia (Charges in Rs/Hour) |

| 01 |

Ultra precision 5 Axes Micro Machining Centre – KERN EVO |

2600 | 1800 |

| 02 |

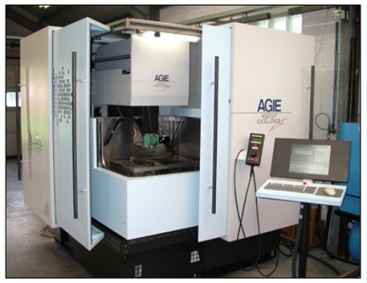

Micro Wire Electro Discharge Machine (µ-WEDM) - AGIE EXCELLENCE 2F |

3000 | 2000 |

| 03 | Hard Turn- mill centre - HARDINGE | 2400 | 1600 |

| 04 |

Multipurpose µ-EDM Machine – DT 110MICROTOOLS |

2400 | 1600 |

| 05 |

Universal Tool and Cutter Grinder Machine - EWAG |

2400 | 1600 |

| 06 |

Precision CNC Lathe - Schaublin125 CNC |

1000 | 600 |

| 07 |

Universal cylindrical grinding machine - Kellenberger 1000 U-175 |

1200 | 800 |

| 08 |

Precision Surface grinding machine–Tripet S.A. |

1200 | 800 |

*The rates of the services shall be changed periodically. Please contact us for exact prices. Cost of the equipment is based on the usage on a per hourly basis. 18% GST Extra.

Precision Manufacturing & Process Engineering group is equipped with micro machining facilities with state-of-the art equipment / machines for manufacture of components with miniature features and accuracies in the order of few microns.

- Min Drilling Capability : Ø 30 µm

- Min Milling Capability : Ø 50 µm

- Maximum Spindle speed : 50000 Rpm

- Positional Accuracy : 2 µm

- Manufacturing of micro components.

- Drilling of very small/fine holes.

- Micro channels, micro needles.

- Medical implants, Dental implants.

- Micro dies and micro molds.

- Minimum wire diameter : 30 µm

- Profile Accuracy : 4 µm

- Surface Finish (Ra) : 0.1 µm

- Dies & punchers Micro surgical tools & bio medical devices.

- Thin walled structural parts for Aerospace application.

- Micro channels, Micro dies and molds.

- Machining of Hard Materials up to: 68 HRc

- Maximum turning length : 610 mm

- Maximum Spindle speed : 4200 RPM

- Maximum swing over bed : 519 mm

- Roundness : 0.5µm

- Surface Finish (Ra) : 0.2 µm

- Positional Accuracy : 5 µm

- Machining of hard material upto 68HRc

- Machining of bearing steels

- Machining of hot and cold work tool steels

- Machining of high speed steels

- Machining of die steels

- Working range: X: 200mm, Y: 100, Z: 100mm.

- Spindle speed : 1 – 300 RPM

- Min micro hole drill size : 10 µm

- Micro EDM Sinking min feature size: 50 µm

- Micro shafts & pins

- Micro gears

- Micro filters

- Miniature surgical tools

- Medical implants

- Work head swivel axis, A : -135°/+30°

- Work head inclination axis ,C : ±15°

- In process Measurement capability

- Form tool grinding

- Cutting tools re sharpening

- Customized tools grinding

- Height of centers: 125m

- Maximum distance between centre : 500mm

- Permissible diameter above bed : 270 mm

- Permissible diameter above slide : 130 mm

- Permissible diameter in spindle bore: 28mm

- Permissible diameter in collet B32 :24mm

- Maximum diameter of chuck : 150mm

- Spindle speed ,step less :0-5000 rpm

- Traverse travel,X-axis : 180mm

- Longitudinal travel,Z-axis : 410 mm

Machining of cylindrical parts with high precision.

- Distance b/w centers:1000mm

- Height of centers:175mm

- Max swing over table:349mm

- Max travel of table:1300mm

- Spindle speed:1500-2200rpm

- Precision cylinder grinding

- Surface grinding

- Internal grinding

- Face grinding

- Tool grinding & execution of special grinding operation

Specifications:

- Maximum slide movement: 530 X 220 mm

- Maximum grinding area : 500 X 200 mm

- Table working surface : 600 X 200 mm

- Variable speed drive : 1150 – 3300 Rpm

- Vertical & Transverse feed movement

- By hand wheel 1 division : 0.01 mm

- By micrometer adjustment : 0.001 mm

- Surface grinding with ultra-precision.

- Form grinding.

Mr. Sunil Magadum

Scientist – D

Group Head for Micro-Nano Manufacturing

Centre for Micro-Nano Manufacturing and Metrology (C-MNTM)

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru – 560022

Phone: +91-80-22188391

E-Mail: sunilm[at]cmti[dot]res[dot]in

Mr.Karthik M S

Scientist B

karthik[at]cmti[dot]res[dot]in

+91-80-22188383

Mr. K. Niranjan Reddy

Joint Director & Centre Head (C-MNTM)

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru-560022

Phone (Office): +91-80-22188379

Mobile: +91-9449842672

Fax: +91-80-23370428

E-mail: niranjan[at]cmti[dot]res[dot]in

Precision Manufacturing & Process Engineering Group

Centre for Micro-Nano Manufacturing and Metrology (C-MNTM)

CMTI, Tumkur Road, Bangalore – 560022