- project

- service

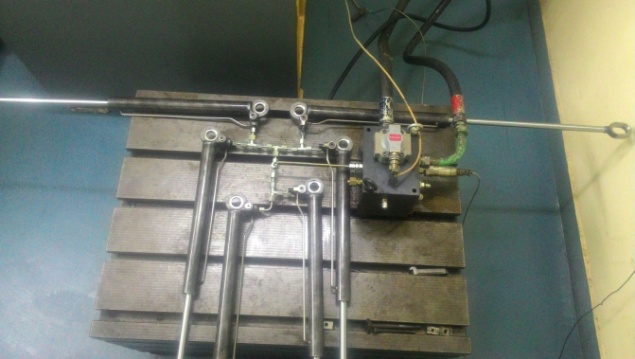

Testing of Hydraulic elements

| Sl. No. | Name & Specifications | Photo |

|---|---|---|

| 1 | Impulse Pressure Test of Retraction Actuator (RA PT-01) for Rustom II – UAV i. Testing as per MIL-PRF-5503F. |

|

| 2 | Performance test on centrifuge for Alfa laval

|

|

| 3 | Pressure Impulse Test on Ti Tubes Pressure impulse testing of indigenous Ti-Tubes as per SAE ARP 1383. |

|

| 4 | Pressure Impulse test on Hydraulic cylinders (Pricol) i. No of Cylinders: 6 nos. |

|

Other Misc. Testing

- Onsite performance testing of the centrifugal separator developed by M/s Alfa Laval India Pvt. Ltd, Pune, and M/s GEA Westphalia Separators India Pvt. Ltd., Bangalore.

- Test setup for pressure cycling of the parker filters at 40°C and 80°C, and filter assembly for its fatigue strength test. Pressure cycling tests on hydraulic filters were carried out for 0-8 bar at 5Hz for Parker Hannifin.

- Hot soak and Cold soak of hydraulic cylinders for 24 hrs and performance test on hydraulic cylinders for Wipro Ltd.

- Drum Top Filtration unit was tested by the portable particle counter for its performance for Tri-Millennial Design and Service Engineers Pvt. Ltd.

- Flow Fatigue test of the Hydraulic filters was carried out for 9 bar differential pressure at 1Hz for Micro Precision

- Burst pressure testing of Welded D-Tube and Pressure drop and thermal efficiency test of a cold plate for RangsonsDefense Solution Pvt. Ltd, Bangalore

- Static Pressure testing (pneumatic) of 105 nos. fire extinguisher cylinders of Southern Electronics Pvt. Ltd., Bangalore Pressure drop test and burst pressure testing of Direction control valves, Dynamatic Technologies Ltd, Bangalore

- Performance test on Avionic cold plate was carried out with test fluid, Poly Alfa Olephin (PAO) at 60 °C and flow rate 0.7 GPM for Ranson defence solutions.

- Single-pass performance testing on Filter elements for Gopani Product Systems.

- Filtration efficiency test and dirt holding capacity test on Spin-on filters were taken up and completed for BEML Mysore, Parker Hannifin, Ind Auto filters, Sany Heavy Industries India Pvt. Ltd., Ultrafilter (India) Pvt. Ltd., Micro Precision, Micropore.

- Total no of filters tested for efficiency: 112nos

- Total no of filters tested for pressure cycling: 11nos

- Testing services in the field of Industrial Hydraulic Elements.

- Performance Test of Industrial pumps, control valves, cylinders etc

- Thermal Performance test, Endurance test, ageing test, thermal shock test etc.

- Characterization of Industrial hydraulic elements.

- Hydrostatic pressure testing.

- Pressure cycling test on hydraulic elements.

- Cold / hot soak and performance test on hydraulic elements.

- Validation of oil/fuel filter performance by Multi-pass or single pass method, dirt holding capacity, collapse rating etc.

- Laboratory services.

- Measurement of oil contamination level by particle count (ISO 4406 & NAS 1638)

- Component cleanliness level checking

- Calibration of Pressure gauges.

- Supply of calibration fluid

- Supply of ultra-clean bottles