The Laser Processing provides leading-edge laser micromachining solutions to industry and research. Using its own experienced staff and dedicated state-of-the-art femtosecond & UV-laser micromachining systems, and offers a complete flexible, cost-effective laser processing service by high precision, micro and nano-machining of components made of metals, polymers and semiconductors etc.

- Services

- Facilities

- Contact

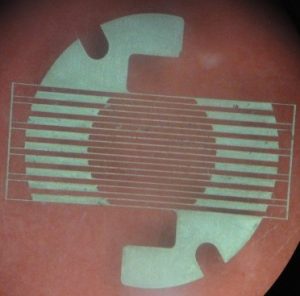

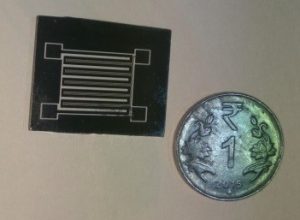

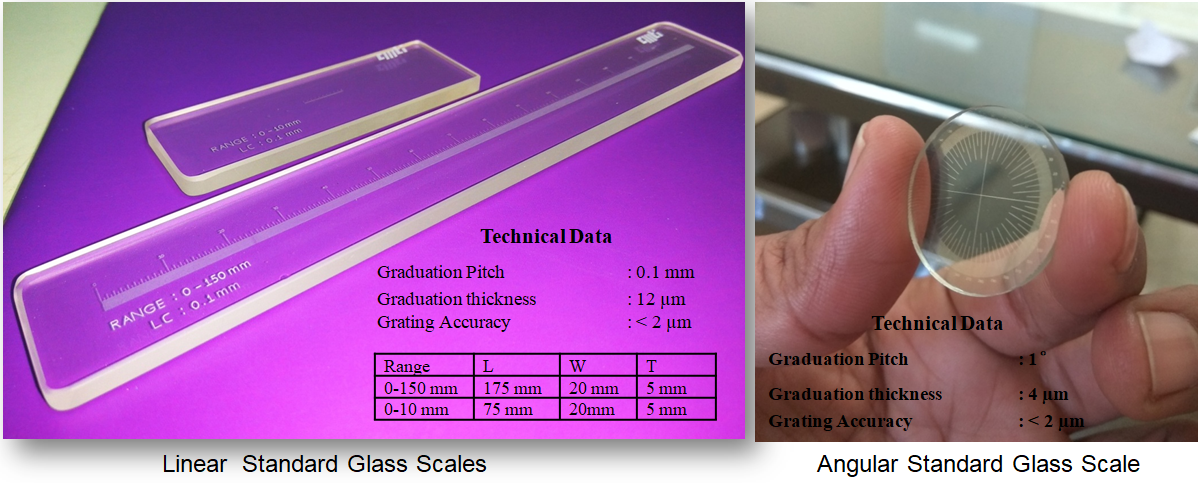

Metrology Artefacts Fabrication

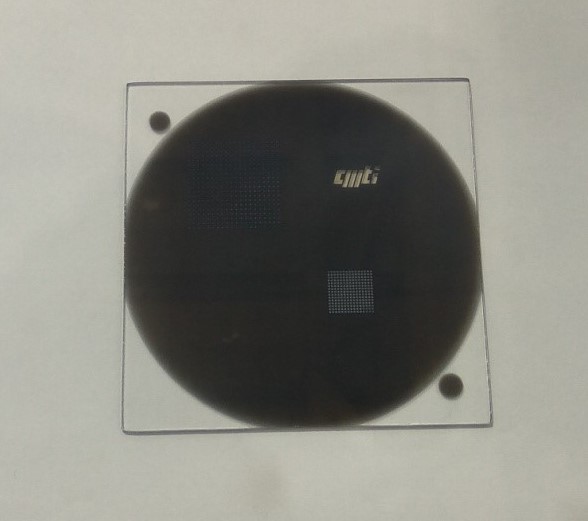

High precision optical standard glass scales

CMTI has developed high precision optical standard glass scales by using state of the art facility available in the Institute. These artefacts are used for the measurement, inspection, calibration and positioning in Imaging Equipments, Microscopy, Scanning etc. The Grating straightness & pitch accuracy of the developed artefacts is within 1 µm.

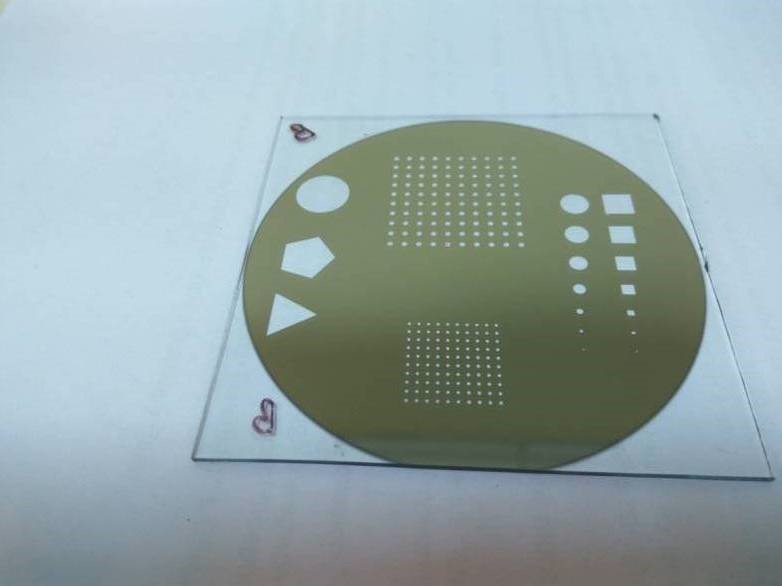

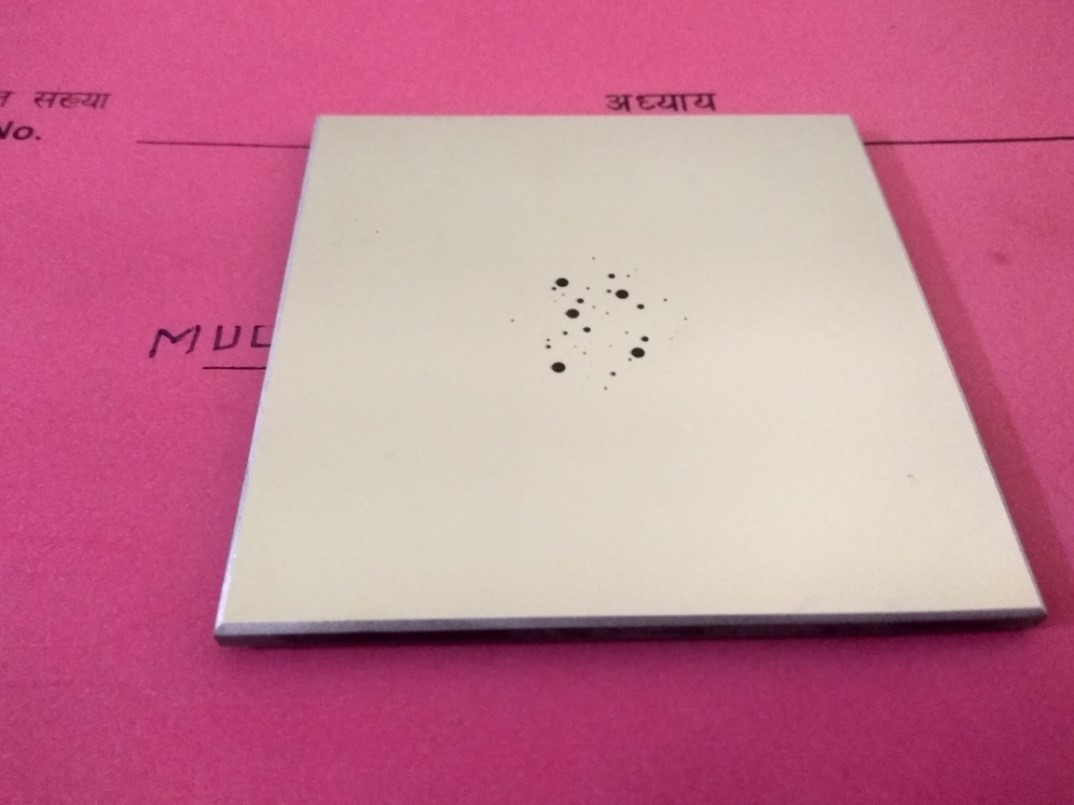

High precision optical standard calibration masks

CMTI has developed the high precision optical standard calibration masks for the calibration of Microscopy equipments.

Diamond Marking

We undertake the work regarding marking diamonds for their identification and tracking with well established laser process.

Fabrication of Microfluidic Channels and devices

With state of the art laser micromachining facilities, CMTI will fabricate and supply microfludic channels and devices made out of variety of materials.

Fabrication of micro-needles for bio-medical applications

CMTI has developed square and circular micro-needles on Stainless steel and PMMA materials for drug delivery applications.

Micromachining Services

CMTI will take up all types of micromachining works like fabrication of sputtering masks, micro-cantilevers, microheaters etc using all types of materials with highest possible accuracy.

Service Charges:

| Sl No. | Facility | Charges in Rupees/Hour | |

| Industry | Academia | ||

| 1 | Femto Second Laser Micromachining | 6100 | 4000 |

| 2 | Excimer Laser Micromachining | 6500 | 4100 |

*The rates of the services shall be changed periodically. Please contact us for exact prices. Cost of the equipment is based on the usage on a per hourly basis. 18% GST Extra.

Wave length : 193 nm (ArF) & 248 nm (KrF)

Pulse duration : 20 ns

Repetition rate : 1-50 Hz

Beam size : 24 x 10 mm

Minimum feature size : 1.5 µm

Traverse X, Y & Z Axis : 200 x 200 x 50 mm

Micromachining & Processing of Polymers, Thin Metal Films etc

Wave length : 775 nm

Pulse width : 10 ps to 150 fs

Repetition rate : 1 Hz to 2 KHz

Resolution : 1 nm

Minimum feature size : 1 µm

Traverse X, Y & Z Axis : 150 x 150 x 100 mm

Micromachining of Metals, Glasses, Ceramics, Semiconductors & Polymers etc

Mr. Sunil Magadum

Scientist-C,

E-Mail: sunilm[at]cmti[dot]res[dot]in

Phone: +91-80-22188361

Mr. K Niranjan Reddy

Joint Director & Centre Head (C-MNTM)

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru-560022

Phone (Office): +91-80-22188379

Mobile: +91-9449842672

Fax: +91-80-23370428

E-mail: niranjan[at]cmti[dot]res[dot]in

Laser Processing Group

Centre for Micro-Nano Manufacturing and Metrology (C-MNTM)

CMTI, Tumkur Road, Bangalore – 560022