- Introduction

- People

- Research Areas

- Projects

- Services

- Facilities

- Achievements

- Gallery

- Contact

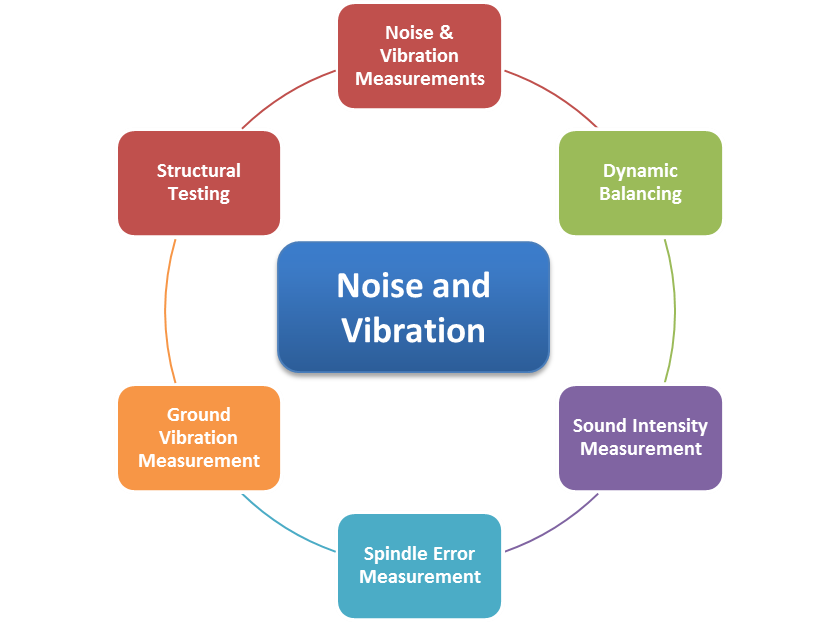

Noise and Vibration Laboratory, caters to the measurement of parameters like Force, Displacement, stress and strain in machine tools and components. The laboratory is equipped with qualified, trained and experienced Technical Staff and state of the art facility for measurement and analysis of various parameters such as Sound, Vibration, Temperature, Spindle Error Measurement, Dynamic balancing, Structural Testing etc.

Noise and Vibration laboratory at CMTI:

- Is capable of investigating one off problems from fundamentals and offer technology solutions

- Equipped with qualified and trained man power in noise and vibration and instrumentation.

- Equipped with measuring and analysis equipment which are configured on a case-to case basis in tune with the needs of the situation/problem being investigated.

- Partnered and added value to the efforts of customers in enhancing their productivity, product quality and improving environmental conditions.

- Has design and development capability for modernizing testing equipment and systems

- Has trained customers in noise and vibration aspects.

Download : Noise & Vibration Lab Service Brochure

| Centre Head | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

|

Mr. Prakash Vinod | Joint Director | View Profile |

| Group Head | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

| Scientists | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

|

Mr. Girish Kumar M | Scientist - E | View Profile |

| Technical Staff | |||

| Photo | Name | Designation | Phone (Office) |

|---|---|---|---|

|

Mr. Mukunda M | Senior Technical Assistant - I | 080-22188246 |

| Administration | |||

| Photo | Name | Designation | Phone (Office) |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

- Problem investigation, analysis and mitigation - both Immission and Emission aspects of Noise and Vibration

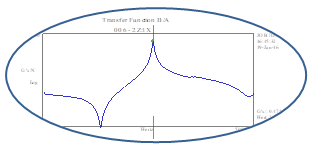

- Dynamic behaviour studies (Transfer Function (FRF), Compliance Frequency and Dynamic Stiffness Measurements), Modal Analysis of Structures & Machinery & Operation Deflection Shapes (ODS) Analysis.

- Dynamic Balancing of Rotors: In-Situ using portable equipment and on Balancing Machines -- special ultra-precision balancing tasks.

- Assisting industries to adapt Predictive Maintenance practices through Vibration Monitoring.

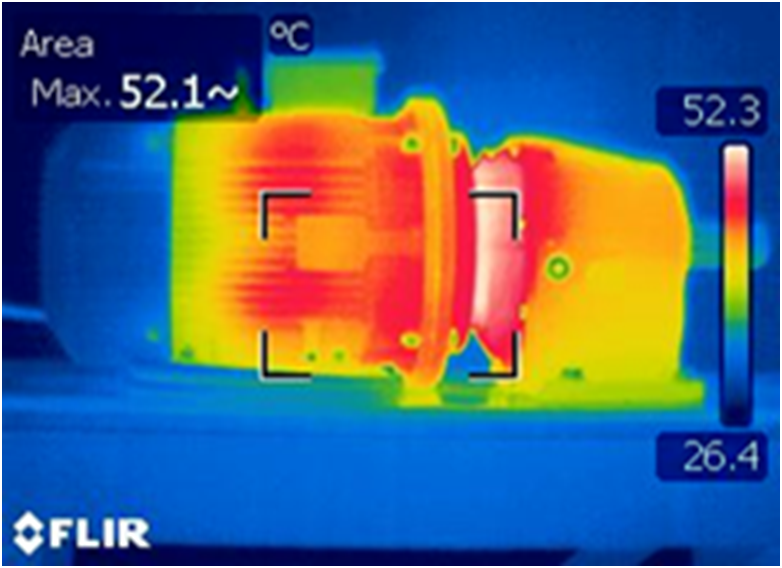

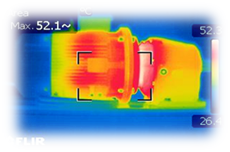

- Condition Monitoring of Machine Tools, Machines, Transformers, Circuit Breakers, Motors, Control Panels, Furnaces etc., through Infrared Thermography.

- Thermal Mapping, Investigation and Condition Monitoring: Improving the machine design by experimentally evaluating heat zones, heat flow pattern, thermally induced stresses and in investigating the thermo elastic behavior of machines, condition monitoring of machines, structures, Electrical Panels, etc….

- Structure Borne and Air Borne noise measurement on Structures, Machinery and Electro Mechanical Systems.

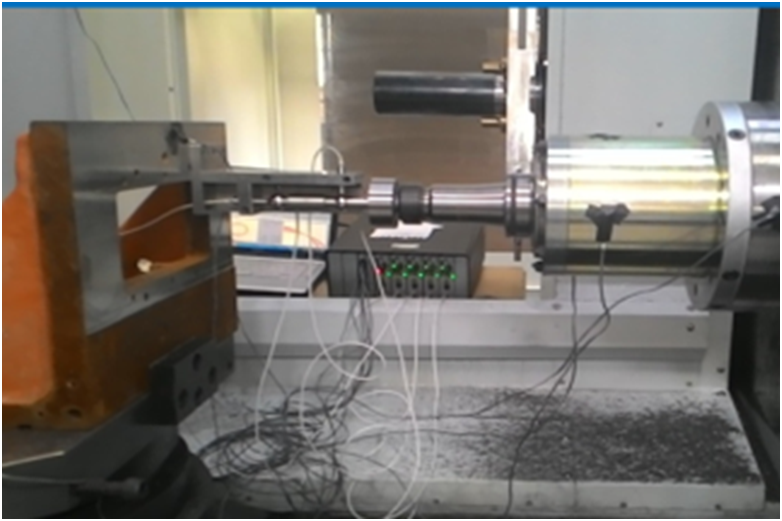

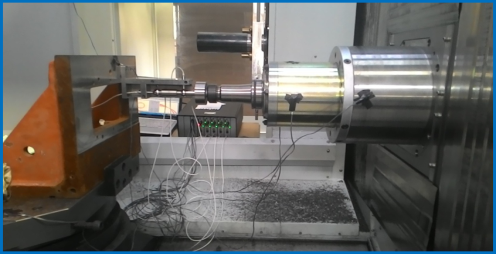

- Spindle Error Measurement of High Precision Spindles.

- Environmental Noise & Vibration Assessment (Ground Vibration Measurement and Analysis)

- Sound Intensity Analysis for Sound Power Measurement, Noise Mapping, Noise source Identification and Ranking

- Training and Consultancy in Noise and Vibration and Condition Monitoring.

Initially the vibration measurement was carried out on the engine in decoupled condition to know the existing vibrations, when it is supported on jacks. The abnormal vibrations of the order of 69.3 mm/sec was noticed in this condition and the detailed analysis was carried out and the analysis results depicts, the problem was due to 1.2mm run out in the engine stub shaft.

This engine stub shaft run out was resulting into higher unbalance induced vibration. Finally the stub shaft run out problem was corrected. The existing vibration level came down to 20mm/sec. Further analysis was pointing out to lesser structural rigidity of the based frame. The structural rigidity of the base frame was modified by the OEM to increase the stiffness and rigidity of the structure. Finally, the vibration level came down to less than 5mm/sec.

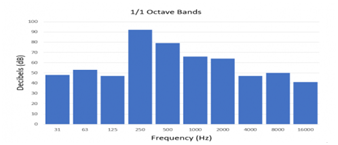

Task: Noise and Vibration Analysis of Motor Cycles by Time Event Analysis, FFT Analysis, 1/3 octave analysis, Order Tracking & waterfall Analysis, Transfer Function Analysis of Motor Cycle Elements to identify the resonant frequencies. All these techniques are used simultaneously to identify improvement areas in the motor cycle.

Results: – We identified major improvement points for reduction of noise emitted from the engine for the customer. In the first instance engine noise level was brought down by 8 dBA

Task: The task involved the noise and vibration measurement of load haul dumper used in underground mining. The noise and vibration measurement of the load haul dumper was carried out as per the test conditions mentioned in the standards (ISO2631-1, ISO6394, and SAE J88).

Result: – Improved design of seat isolators effected with a better understanding of the customer perception in respect of conflicting requirements arising for vibration isolation and damping during dumping operation and vehicle movement on plain ground.

Task: This task pertains to the noise and vibration measurement of transformer under full load condition. The vibration acceleration (ref. 1E-05 m/s2) was measured in 1/3rd octave bands (25Hz to 8kHz) at 4 mounts of the transformer, when the transformer was operating under full load condition. The mean vibration acceleration values are compared with the allowable limit values specified by the NES 537.

Result: – Improved design of transformer base and selection of appropriate low cost vibration isolators based on the measurement results and to meet the compliance of the standards.

Task: The logarithmic decrement & FRF measurements of mild steel solid and riveted beams were carried out in order to find out the natural frequencies & damping coefficient factor of the beams. The measurements were carried out on mild steel beams in cantilever condition.

Result: – Improve the of riveting process while joining the two mild steel beams and maintain the equal space between the joints to achieve the good damping value. The higher damping and stiffness values are noticed in composite material.

Task: This task pertains to the Noise, Vibration and Thermography measurements carried out on intaglio printing machines. The measurements were carried out during printing and impression cylinder off condition to assess bearing condition of the plate cylinder and impression cylinder bearings.

Result: – Improved the life of bearing of printing drum by measuring the temperature and vibration on the printing drum during maximum printing condition (10000 sheet per Hour).

Task: The task involved dynamic balancing of the USUPTM Spindle assembly. The vibration measurements were carried out on spindle to know the magnitude of unbalance-induced vibration. The vibration severity level was measured in the frequency band of 0-1kHz.

Result: – To achieve the surface roughness of less than 1 nanometer, we balancing the spindle to less than G0.4 grade. We achieved the balancing grade less than the G0.1 grade.

Task: Identification and ranking of different noise sources of Tractor

Technique: Measurement of sound intensity over a surface of a complex and multiple noise sources.

Result: The investigation led to redesign of engine and transmission element assembly features. Predominant noise source components in the tractor are identified and ranked to help in product development to reduce the noise level further in order to meet the Environmental Norms.

Task: The task involved measurement of structure borne noise and sound intensity measurement of Kochi HVAC Unit. The measurement was carried out at different operating condition as per customer requirement and the results are given below. The sound intensity measurement were carried out as per ISO 9614-2, when the VAC Unit running in full cooling mode (all the elements are running)

Result: The investigation led to know the maximum noise generated by the HVAC unit element. Predominant noise source components in the HVAC are identified and ranked to help in product development to reduce the noise level further in order to meet the Environmental Norms.

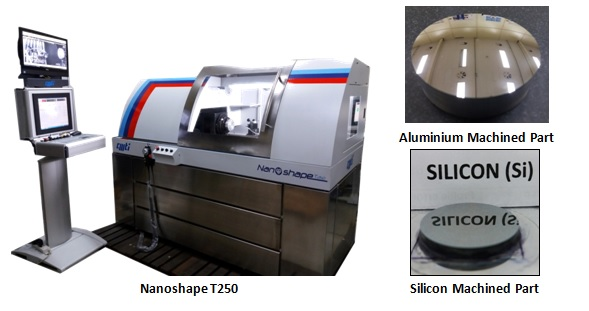

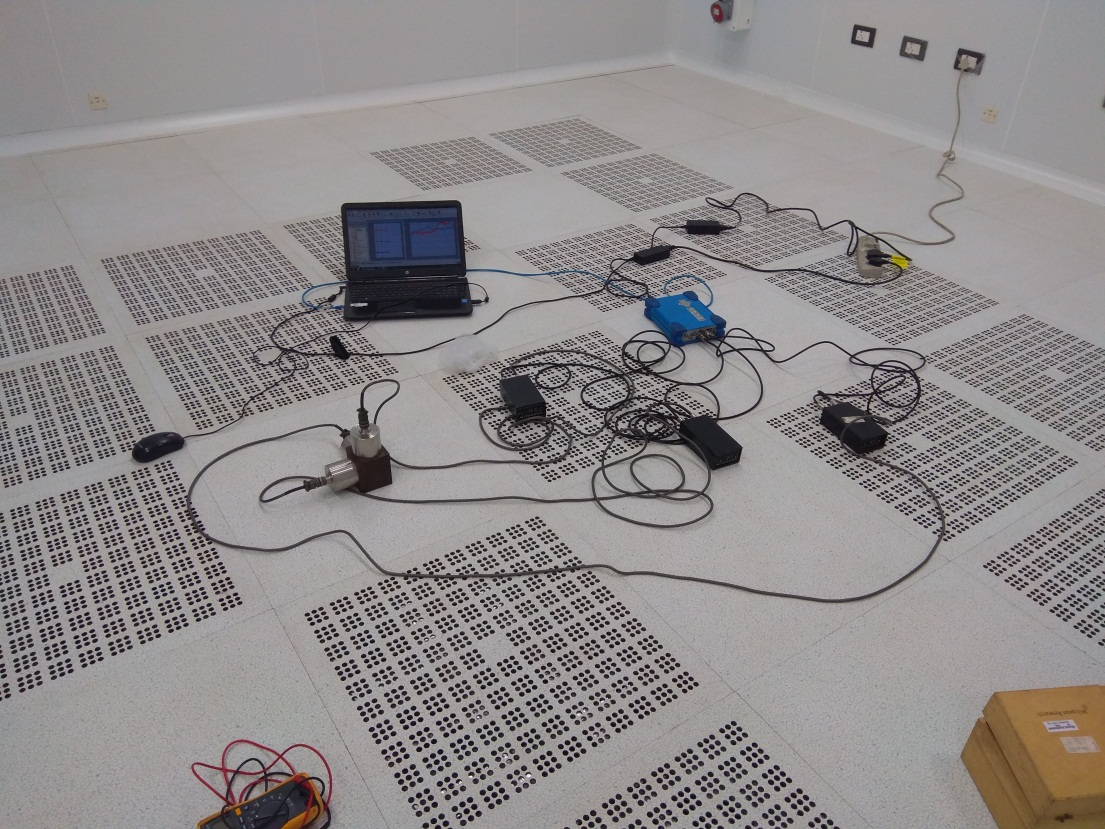

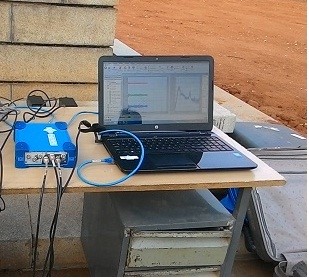

Task: The task involved measurement of ground vibration at inside the underground clean room lab area. The ground vibration due to movement of traffic, men, machine and other environmental activities were measured to know the existing ground vibration levels.

Result: The ground vibration measurement values give the selection of isolators for the machined to be installed at the particular area. Before installing any high precision machine like CMM, Diamond Turning and any Metrology equipment we should measure the existing ground vibration levels to select proper isolators

Task: The task involved the structure borne noise tests of a HVAC Unit for Kochi Metro. The structure borne noise carried out on the seat supports and handle for passenger support to know the vibration level experienced due to the running of HVAC unit inside the coach.

Result: The ground vibration measurement values give the selection of isolators for the machined to be installed at the particular area. Before installing any high precision machine like CMM, Diamond Turning and any Metrology equipment we should measure the existing ground vibration levels to select proper isolators

Task: Balancing of the propellers was carried out on SCHENCK R2BU Dynamic Balancing Machine. The Propeller was mounted on the mandrel made for the purpose of balancing. The Mandrels were first balanced to a quality grade of better than G0.4 (as per ISO-1940). The propeller was then mounted on the mandrel and balanced to a quality grade of better than G1 grade.

Result: The dynamic balancing of propeller to less than G1 grade for the better performance during the application.

- OROS Dynamic Real Time Signal Analyser

- Meggitt-Seismic Accelerometer

Make & Model: OR-34 and 731A

- Scientist = Rs. 1430 per hour + GST

- Technician = Rs. 715 per hour + GST

2. Charges towards utilization of

Equipment’s/Instruments will be based on cost of Equipment’s/Instruments.

3. Reporting Charges: Varies from Case to Case basis

Mr. Girish Kumar M (Scientist-D)

Email: girishkumar[at]cmti[dot]res[dot]in

Land Line: +91-80-22188390

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

OROS Dynamic Real Time Signal Analyser

Make & Model: OR-34

- Scientist = Rs. 1430 per hour + GST

- Technician = Rs. 715 per hour + GST

2. Charges towards utilization of Equipment’s/Instruments will be based on cost of Equipment’s/Instruments.

3. Reporting Charges: Varies from Case to Case basis

Mr. Girish Kumar M (Scientist-D)

Email: girishkumar[at]cmti[dot]res[dot]in

Land Line: +91-80-22188390

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

Scheck Horizontal Balancing Machine Make & Model: Scheck – CAB 690

- Scientist = Rs. 1430 per hour + GST

- Technician = Rs. 715 per hour + GST

2. Charges towards utilization of Equipment’s/Instruments will be based on cost of Equipment’s/Instruments.

3. Reporting Charges: Varies from Case to Case basis

Mr. Girish Kumar M (Scientist-D)

Email: girishkumar[at]cmti[dot]res[dot]in

Land Line: +91-80-22188390

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

Machinery Health Analyser, Accelerometer and Tachometer.

Make& Model: CSI , B& K and Monarch

- Scientist = Rs. 1430 per hour + GST

- Technician = Rs. 715 per hour + GST

2. Charges towards utilization of Equipment’s/Instruments will be based on cost of Equipment’s/Instruments.

3. Reporting Charges: Varies from Case to Case basis

Mr. Girish Kumar M (Scientist-D)

Email: girishkumar[at]cmti[dot]res[dot]in

Land Line: +91-80-22188390

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

Data Acquisition System ,Impulse Hammer and Accelerometer

Make& Model: OROS, CSI and B& K

- Scientist = Rs. 1430 per hour + GST

- Technician = Rs. 715 per hour + GST

2. Charges towards utilization of Equipment’s/Instruments will be based on cost of Equipment’s/Instruments.

3. Reporting Charges: Varies from Case to Case basis

Mr. Girish Kumar M (Scientist-D)

Email: girishkumar[at]cmti[dot]res[dot]in

Land Line: +91-80-22188390

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

Sound Intensity System

Make & Model: GRAS-50AI-D

- Scientist = Rs. 1430 per hour + GST

- Technician = Rs. 715 per hour + GST

2. Charges towards utilization of Equipment’s/Instruments will be based on cost of Equipment’s/Instruments.

3. Reporting Charges: Varies from Case to Case basis

Mr. Girish Kumar M (Scientist-D)

Email: girishkumar[at]cmti[dot]res[dot]in

Land Line: +91-80-22188390

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

FLIR

Make& Model: T350

- Scientist = Rs. 1430 per hour + GST

- Technician = Rs. 715 per hour + GST

2. Charges towards utilization of Equipment’s/Instruments will be based on cost of Equipment’s/Instruments.

3. Reporting Charges: Varies from Case to Case basis

Mr. Girish Kumar M (Scientist-D)

Email: girishkumar[at]cmti[dot]res[dot]in

Land Line: +91-80-22188390

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

Spindle Error Analyser

Make& Model: Lion Precision,USA

- Scientist = Rs. 1430 per hour + GST

- Technician = Rs. 715 per hour + GST

2. Charges towards utilization of Equipment’s/Instruments will be based on cost of Equipment’s/Instruments.

3. Reporting Charges: Varies from Case to Case basis

Mr. Girish Kumar M (Scientist-D)

Email: girishkumar[at]cmti[dot]res[dot]in

Land Line: +91-80-22188390

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

Noise and Vibration Sensors

| Vibration and Noise Measurements Sensors | Type and manufacturer | Specification |

| Accelerometers | Uni-Axial B & K- Denmark |

Frequency Range: 1Hz to 10kHz Sensitivity: 99.43mV/g Dynamic Range:+/- 50g Peak Working Temperature Range: Application: Vibration Measurement on non-Rotating Elements. |

| Tri-Axial Kistler-Switzerland |

Frequency Range: 20Hz to 10kHz Sensitivity: 10mV/g and 1000mV/g Dynamic Range: +/-500g and +/- 5g Working Temperature Range:-540C to 1200C Application: Vibration Measurement on non-Rotating Elements for a Lower Frequency Range, Like ground Vibration Measurement( |

|

| Uni-Axial CSI-USA |

Frequency Range: 1Hz to 10kHz Sensitivity:100 mV/g Dynamic Range:+/- 50g Peak Working Temperature Range: Application: Vibration Measurement on non-Rotating Elements |

|

| Uni-Axial Meggitt-UK |

Frequency Range: 0.1Hz to 320Hz Sensitivity:10.4 V/g Dynamic Range: 0.5g Peak Working Temperature Range:

|

|

| Moicrophones (IEC 61672 Class 1) |

PCB-USA | Frequency Range: 3.75 Hz to 20kHz Sensitivity: 47.53mv/Pa Dynamic Range: 137dB Working Temperature Range: -400c to 1500C Application: Sound Pressure Level Measurement of Rotating Elements. |

| Impulse force Hammer | A034703 and A034701 CSI-USA |

Frequency Range: 0 Hz to 8kHz Sensitivity: 0.23mV/N and 2.3mV/N Dynamic Range: 22200N and 2200N Application: Find the natural frequencies of components |

| Sound Level Meter | 2130 B& K- Denmark |

Frequency Range: 20Hz to 20kHz Dynamic Range: 130dB Application: Overall Sound Pressure Level Measurement of Rotating Elements. |

| Sound Level Calibrator | Type 42AB GRAS-France |

Precision Integrating Sound Level meters Type-0 and Type-1 as per IEC Generates 114 dB at 1000Hz |

| Vibration Calibrator | Type | · Portable Handheld accelerometer calibration exciter for field calibration check of transducers · Generates 1g at 159.6Hz |

Data Acquisition System

| DAQ System |

Type and manufacturer | Specification |

| OROS 4 Channel Data Acquisition System |

OR-34, OROS-France |

Frequency Range: 0 Hz to 40kHz Features: 24 bit, 4 Channel Real Time Analyser ,1/3rd octave band Measurement, Data Recording and Analysing Application: Noise and Vibration Related Measurements , |

| Data Physics 8 Channel Data Acquisition System |

DATA PHYSICS -USA | Frequency Range: 0 Hz to 40kHz Features: Portable, Battery operated 8 Channel with advanced noise and vibration analysis software like FFT, Waterfall, Octave, Order Tracking, Modal Analysis Software, Data Recording, Multi Analysis software. Application: Noise and Vibration Related Measurements, Modal Analysis, Operational Deflection shape and Experimental Modal Analysis. |

Sound Intensity System

| SI System | Type and manufacturer |

Specification |

| Sound Intensity System | OR-34, OROS-France |

Frequency Range: 0Hz to 10kHz Features: PC based Sound intensity measurement & Analysis system for Noise source Identification and ranking, Noise level contour mapping and sound power measurement Application: Sound Power Level Measurement. |

Spindle Error Analyser

| SEA System |

Type and manufacturer | Features |

| Spindle Error Analyser system |

CPL290 Lion Precision-USA |

Measure Spindle running accuracy and Thermal growth of Spindle at any time instant. |

Thermography System

| SEA System |

Type and manufacturer | Features |

| Thermography system |

FLIR | Portable, Battery Operated used in improving the machine design by experimentally evaluating heat zones, heat flow pattern and thermally induced stresses. The system should help in investigating the thermo elastic behaviour of machines. Condition monitoring of machine tools, machines, transformers, circuit breakers, motors, control panels, furnaces etc., The temperature range of camera is from 00C to 6500C. |

Dynamic Balancing Machine

| SEA System |

Type and manufacturer | Features |

| Dynamic Balancing Machine |

CAB 690 | Dynamic Balancing of Armatures, Spindles, Mandrel, Rotors, Propellers upto G0.4 Grades as per ISO 1940. Max Diameter |

| Machinery health Analyser | 2130 CSI-USA |

CSI 2130A2 with Machinery health manager, Advanced vibration analysis, Advanced cross channel analysis, ODS (Operation Deflection shape) & Modal analysis software’s |

- Non-contact vibration measurement in the field or in the lab

- Measurement range (mm/s/V): 5, 25 and 125

- Full scale output (peak, mm/s): 20, 100 and 500

- Velocity resolution1 (μm s-1/√Hz): <0.02

- Portable, robust and reliable sensor with laser precision

- Versatile measurements from up to 22 kHz

- Variable stand-off distances from 0.09 to ca. 30 m

- Eye-safe, visible laser for easy positioning and adjustment

- Laser Type: Helium Neon (HeNe)

- Laser wavelength 633 nm, visible red laser beam

- Stand-off distance3 90 mm … ~ 30 m

Fulfils ISO 3741, ISO 3744, ISO 3745, ISO 3747 and ISO 6926 for calibrated sound power sources.

Frequency Range from 50Hz to 20kHz.

Sound Power Output 91dB re 1pW (A-weighted, 50Hz line frequency)

Comparison method for determination of sound power of noise sources according to ISO 3741.

Measurement of environmental correction, K2 according to ISO 3744.

Sound absorption measurements

Sound insulation measurements.

Low Frequency Ground Vibration Measurement, Ground Vibration Survey, Ground Vibration Measurement for Precision Metrology Equipment’s before and after the installation.

Noise and Vibration Measurements, FFT Analysis, FRF Measurement (Natural Frequency Testing), Octave Analysis (1/1, 1/3rd, 1/nth), Data Recording, Multi-Channel Multi Analysis, Run-up and Rundown Measurement, Trend Analysis, 3D Waterfall Analysis and Frequency v/s Time Map, Time Domain Analysis, Synchronous Order Tracking/Analysis, FFT Diagnostics Module, Envelop Detection. Cepstrum Analysis.

Noise and Vibration Measurement, Frequency Response Function (Natural Frequency Testing), Dynamic Balancing, Route Based Data Collection and Analysis for Condition Monitoring, Time Domain Analysis, Advanced Cross Channel Analysis, In-Situ Balancing, Order Tracking, Waterfall Diagram

Sound Pressure Level Measurement, Environmental Noise Measurement, Industrial Noise Survey, Sound Power Level Measurement as per ISO 3744 & ISO 3746

Sound pressure level measurement, Environmental Noise Measurement, Industrial Noise Survey.

- Hand-Arm Vibration Measurement (ISO 5349).

- Whole-Body Vibration Measurement (ISO 2631).

- Low-Frequency Whole-Body Vibration Measurement (ISO 2631)

Mining Industry, Process Plants, Earth Moving Machinery’s, Automobile etc

Mining, Process Plants, Earth Moving Machinery’s etc.

ORBIGate Features the following graphics and displays.

- Tabular list: Gap Voltage, Overall, Orders amplitude and phase (0.5X, 1X, nX), Sub1X, Smax.

- Orbits (Overall and nX filtered)

- Full Shaft Motion: Shaft Centerline + Clearance Circle + Orbits

- Bode, Polar and Trend Plots

- Full and Half Spectrum, Cascade and Waterfall

- Gap Voltage Reference

- Slow Roll Vector Reference for Run Out Correction

- Journal Bearing Tools: Gap Voltage Reference, Run Out Compensation.

- Record and Playback.

Turbo Machinery Vibration Analysis (Steam and Gas Turbines, Compressors), Journal Bearing Analysis

- Frequency range Analyser: 10Hz to 80kHz

- Dynamic Range of Hammer:2200n to 22200N

- Features: Portable Analyser, Suitable for finding structural behavior small and larger Structure

- Testing of structural Behavior like Damping value and Natural Frequencies.

- Noise and Vibration Measurement and Analysis.

- Onsite dynamic balancing of spindles and motors.

- Bandwidth: 15000Hz

- Max Speed:10000rpm

- Sensitivity: 80 mV/ µm and 0.4 V/ µm

- Range: 250 µm and 50 µm

- High Precision Spindle Running Accuracy Measurement and Spindle Thermal Growth Measurement

- Frequency Range: 0 Hz to 40kHz

- Features: 24 bit, 4 Channel Real Time Analyser ,1/3rd octave band Measurement, Data Recording and Analyzing

- Marine propulsion certification and maintenance , Wind turbines, gearboxes and transmissions monitoring and maintenance.

- Object Temperature Range: -200C to 6500C

- Focus: Automatic or Manual

- Accuracy:+- 20C

- Emissivity Correction : 0.01 to 1

- Image Storage: JPEG

- Measurement of heat development electrical and mechanical devices, detect blocked pipe work and insulation defects.

- Frequency Range: 0Hz to 10kHz

- Octave Band : 1/3rd Octave

- PC based Sound intensity measurement & Analysis system for Noise source Identification and ranking, Noise level contour mapping and sound power measurement.

- Frequency Range: 20Hz to 20kHz

- Dynamic Range: 130dB

- Overall Sound Pressure Level Measurement of Rotating Elements

- Frequency Range: 0 Hz to 8kHz

- Sensitivity: 0.23mV/N and 2.3mV/N

- Dynamic Range: 22200N and 2200N

- The Measurement of Natural frequencies of spindles, Motor and other sheet metal components

- Frequency Range: 3.75 Hz to 20kHz

- Sensitivity: 47.53mv/Pa

- Dynamic Range: 137dB

- Working Temperature Range: -400c to 1500C

- Sound Pressure Level Measurement of Rotating Elements.

- Frequency Range: 1Hz to 10kHz

- Sensitivity: 1000 mV/g

- Dynamic Range:+/- 50g Peak

- Working Temperature Range: -200C to 1200C

- Vibration Measurement on non-Rotating Elements for a Lower Frequency Range, Like ground Vibration Measurement

Publications:

International / National Journal Publications

- M. Girish Kumar, Prakash Vinod, P V Shashikumar. “A comparative study on road traffic and metro train induced ground vibration at CMTI for establishment of Nano Manufacturing Technology Facilities”. Published in Applied Mechanics and Materials Vols. 592-594 (2014) pp 1991-1995

- M Girish Kumar. “Fault Diagnosis of welded joints through vibration signals using Naïve Bayes Algorithm” at International Conference on Advances in Manufacturing and Materials Engineering, , Published in Elsevier Procedia Materials Science.

- Prakash Vinod, M. Girish Kumar, P V Shashikumar. “Addressing the environmental challenges of Nanometrology Laboratories” Published in MTT, Vol 13, No 4. April 2014

- M. Girish Kumar, Prakash Vinod and P V Shashikumar. “A Study on Ground Vibrations Induced by Metro Train Movement”. Published in MTT, Vol 13, No 7. July 2014

- MusalimaduguKartheek, M. Girish Kumar, Ananda BabuA“A New Approach Based on Wavelet Packet Transform, ANN and Genetic Algorithm Applied to End Milling of Mild Steel on Vertical Milling Machine” Published in MTT, Vol 15, Issue 6. June 2016.

- M. Girish Kumar, Prakash Vinod, P V Shashikumar“Development of an Analytical Method for Dynamic Balancing of Rotors”. Published in MTT Journal

International Conferences

- M. Girish Kumar, Prakash Vinod and P V Shashikumar .“Classification of Road and Metro Train Induced Ground Vibration using Naïve Bayes Algorithm”. Presented paper at International Colloquium on Materials, Manufacturing and Metrology from August 8 to 9, 2014.

- M. Girish Kumar, Prakash Vinod, P V Shashikumar. “Investigation and Analysis of Chatter Vibration in Centerless Bar turning Machine” by at AIMTDR 2014

- M. Girish Kumar, Prakash Vinod, P V Shashikumar. “Ground Vibration Investigation for Establishment of Nano Manufacturing Technology Facilities”. Proceedings of 7th International conference on Advances in Metrology (AdMet-2009), Feb.2009, NPL, New Delhi.

- M. Girish Kumar, Prakash Vinod, P V Shashikumar. “Condition Monitoring of Precision Machine Tool Spindles –Development of Decision Making Aids by Study of Vibration Level and Patterns”. Proceedings of International conference on emerging research and advances in mechanical engineering (ERA-2009), March 2009, VelammalEngg. College, Chennai.

- M. Girish Kumar, Prakash Vinod, P V Shashikumar. “Vibroacoustic Investigation and Mitigation of Noise from Transmission System of Tractors”. Proceedings of International conference on advanced manufacturing & automation (INCAMA-2009), March 2009,Kalasalingamuniversity, T.N.

National Conferences

- Mukunda M, Girish Kumar M, Prakash Vinod. “Prediction of Onset of Bearing Failures in Rotating Machines by Infrared Thermography-An Industrial Case Study”. Published in National Conference on Condition Monitoring proceedings.

- M. Girish Kumar, Prakash Vinod, P V Shashikumar, “Development of Simple Methodology for Dynamic Balancing of Rotors”. National Conference on Emerging Trends in Engineering Technology and Application (NCETETA –2009), April 2009,Shridi Sai Engg College, Bangalore.

- M. Girish Kumar, Prakash Vinod, P V Shashikumar. “A Study on Environmental Conditions for Nanometrology Labs”. 1stNational Conference in Advances in Metrology-AdMet-2011, February 2011, CMTI, Bangalore.

- (Authors) “Online and Real Time Health Monitoring of CNC Machine using MEMS Accelerometer and Wireless Data Acquisition Module” at National Conference (NCCM-2012), June 2012, R&DE, Pune.

- M. Girish Kumar, Prakash Vinod, P V Shashikumar. “A Study on metro train induced ground vibration for establishment of Nano Manufacturing Technology Facilities”

Patent:

- “A method and system for monitoring a machine tool” has been filed.Indian Patent Office Application No:4626/CHE/2015.

- “Low Frequency Portable Vibration Isolation System”.Indian Patent Office Application No:4626/CHE/2015.

- “An Acoustic Enclosure System”Indian Patent Office Application No: 201941032175 dated 08.08. 2019

Trademarks

- Scanning Tunneling Microscope, NanoAvalok STM (Word)

- Indian Patent Office Application No.:3863098, dated: 29.10.2018

- Scanning Tunneling Microscope, NanoAvalok STM (Logo)

- Indian Patent Office Application No.:3863099, dated: 29.10.2018

Mr. Prakash Vinod

Scientist-F & Centre Head –Smart Manufacturing,

Precision Machines Tools and Aggregates

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru - 560022

Phone (office): +91-80-22188243, 23371516

Mobile: +91-9449842680

Fax: +91-80-23370428

E-mail: prakashv[at]cmti[dot]res[dot]in