- Introduction

- People

- Research area

- Projects

- Services

- Facilities

- Achievements

- Gallery

- Contact

The Centre for Micro - Nano Manufacturing and Metrology focuses on services and research &development of high precision components for industrial requirements. In CMTI, work on precision engineering started in the year 1992 and in 1997 an underground building was constructed specifically for the purpose to promote the Precision engineering in the country. The building is one of its kind which had a class 1,00,000 for precision machining and an underground metrology lab with class 10,000 housed 6m below the ground with monolithic anti vibration concrete blocks maintained at 20°±0.5°C and vibration level < 0.2 µm. The department includes metrology laboratory for dimensional metrology with state of art equipments and accredited by NABL.

Presently, the C-MNTM takes up projects sponsored by Indian Industries, Industry consortiums and Government funded R&D and fabrication of high precision miniaturized micro and nano components having feature sizes in the order of lessthan one milli meter. Micro manufacturing is one of the emerging areas and CMTI has well established the facility to meet the requirement of Indian Industry.

Precision Manufacturing & Process Engineering

Precision Manufacturing & Process Engineering group is a part of the Department of Centre for Micro-Nano Manufacturing and Metrology (C-MNTM) at CMTI. Micromachining facility at CMTI with its state of the art infrastructure and expertise promotes the benefit of micromachining and ultra-precision technology for manufacture of micro-components to the Indian industries through consultancy, services and training. Precision Manufacturing & Process Engineering group focuses particularly in development of products indigenisation and fabrication services of high precision parts.

Objectives:

- To offer micro machining services to the industries.

- Develop indigenous machining technology for Micro Parts machining.

- Research and Development to achieve excellence in micro machining technology.

- Human Resource development in the field of micro machining.

- Development of machining technology for import substitution components of various sectors/industries like automobile , aerospace , bio medical, defence etc.

| Centre Head | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

|

Mr. Niranjanreddy K | Joint Director | View Profile |

| Group Head | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

| Scientists | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

| Technical Staff | |||

| Photo | Name | Designation | Phone (Office) |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

| Administration | |||

| Photo | Name | Designation | Phone (Office) |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

- Precision manufacturing and micro machining.

- Indigenous Machining Technology development for newer materials and difficult to cut materials (super alloys)

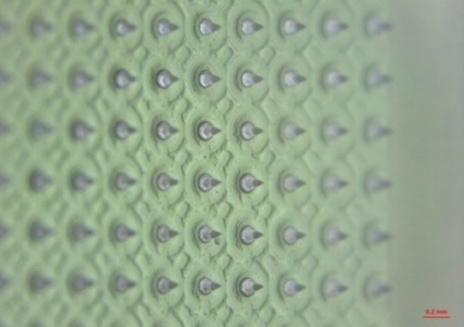

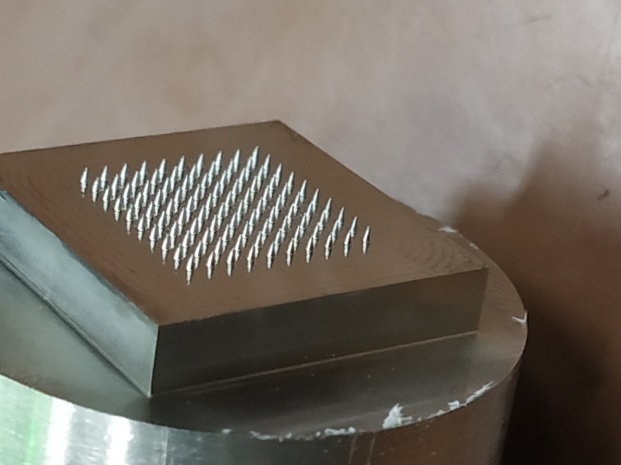

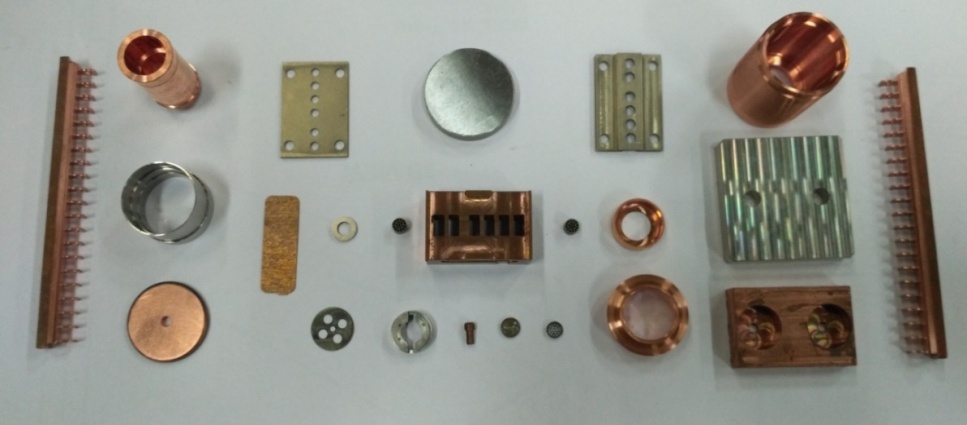

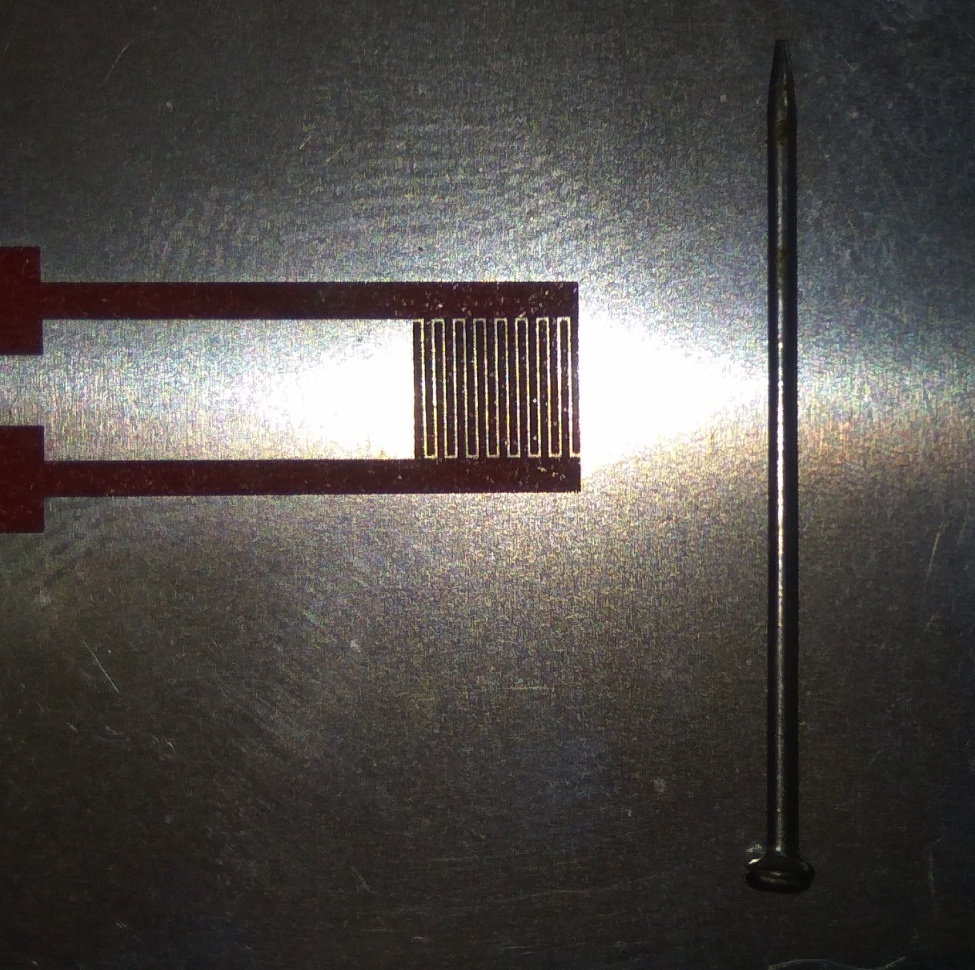

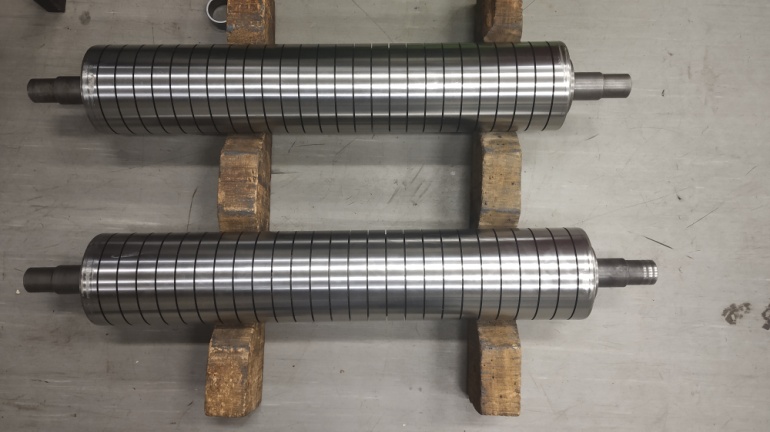

PMPE group has executed many projects towards development of micro components indigenously. Developed high precision components for Aerospace, Defence, Biomedical and Automobile parts that require precision manufacturing technologies comprising micro feature sizes and tight dimensional tolerances less than 5µm.Micro components and features ranging from 5 microns to 2-3 mm and dimensional accuracies from 1 micron to 10 microns have been developed for many applications for the components like micro needles, micro channels, micro fuel injection parts, sensors, biomedical parts etc,. Components like Hyperbolic Feed Rollers for automobile industries, breathing regulators components having low feature sizes and 100% quality acceptance criterion for bio medical application, fuel injector components and gyroscopic flexural components for aerospace industries are being manufactured and supplied to the user industries.

| Sl. No. | Facility | Industry Charges (Rs) | Academia Charges (Rs) |

| 01 | Ultra precision 5 Axes Micro Machining Centre – KERN EVO |

2600 | 1800 |

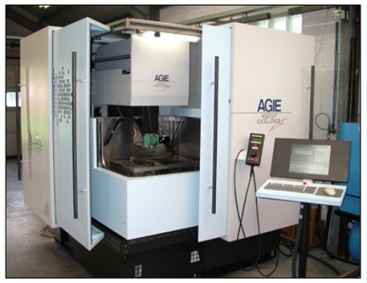

| 02 | Micro Wire Electro Discharge Machine (µ-WEDM) - AGIE EXCELLENCE 2F | 3000 | 2000 |

| 03 | Hard Turn- mill centre - HARDINGE | 2400 | 1600 |

| 04 | Multipurpose µ-EDM Machine – DT 110MICROTOOLS | 2400 | 1600 |

| 05 | Universal Tool and Cutter Grinder Machine - EWAG |

2400 | 1600 |

| 06 | Precision CNC Lathe - Schaublin125 CNC |

1000 | 600 |

| 07 | Universal cylindrical grinding machine- Kellenberger 1000 U -175 |

1200 | 800 |

| 08 | Precision Surface grinding machine–Tripet S.A. |

1200 | 800 |

Precision Manufacturing & Process Engineering group is equipped with micro machining facilities with state-of-the art equipment / machines for manufacture of components with miniature features and accuracies in the order of few microns.

- Min Drilling Capability : Ø 30 µm

- Min Milling Capability : Ø 50 µm

- Maximum Spindle speed : 50000 Rpm

- Positional Accuracy : 2 µm

- Manufacturing of micro components.

- Drilling of very small/fine holes.

- Micro channels, micro needles.

- Medical implants, Dental implants.

- Micro dies and micro molds.

- Minimum wire diameter : 30 µm

- Profile Accuracy : 4 µm

- Surface Finish (Ra) : 0.1 µm

- Dies & punchers Micro surgical tools & bio medical devices.

- Thin walled structural parts for Aerospace application.

- Micro channels, Micro dies and molds.

- Machining of Hard Materials up to: 68 HRc

- Maximum turning length : 610 mm

- Maximum Spindle speed : 4200 RPM

- Maximum swing over bed : 519 mm

- Roundness : 0.5µm

- Surface Finish (Ra) : 0.2 µm

- Positional Accuracy : 5 µm

- Machining of hard material upto 68HRc

- Machining of bearing steels

- Machining of hot and cold work tool steels

- Machining of high speed steels

- Machining of die steels

- Working range: X: 200mm, Y: 100, Z: 100mm.

- Spindle speed : 1 – 300 RPM

- Min micro hole drill size : 10 µm

- Micro EDM Sinking min feature size: 50 µm

- Micro shafts & pins

- Micro gears

- Micro filters

- Miniature surgical tools

- Medical implants

- Work head swivel axis, A : -135°/+30°

- Work head inclination axis ,C : ±15°

- In process Measurement capability

- Form tool grinding

- Cutting tools re sharpening

- Customized tools grinding

- Height of centers: 125m

- Maximum distance between centre : 500mm

- Permissible diameter above bed : 270 mm

- Permissible diameter above slide : 130 mm

- Permissible diameter in spindle bore: 28mm

- Permissible diameter in collet B32 :24mm

- Maximum diameter of chuck : 150mm

- Spindle speed ,step less :0-5000 rpm

- Traverse travel,X-axis : 180mm

- Longitudinal travel,Z-axis : 410 mm

Machining of cylindrical parts with high precision.

- Distance b/w centers:1000mm

- Height of centers:175mm

- Max swing over table:349mm

- Max travel of table:1300mm

- Spindle speed:1500-2200rpm

- Precision cylinder grinding

- Surface grinding

- Internal grinding

- Face grinding

- Tool grinding & execution of special grinding operation

Specifications:

- Maximum slide movement: 530 X 220 mm

- Maximum grinding area : 500 X 200 mm

- Table working surface : 600 X 200 mm

- Variable speed drive : 1150 – 3300 Rpm

- Vertical & Transverse feed movement

- By hand wheel 1 division : 0.01 mm

- By micrometer adjustment : 0.001 mm

- Surface grinding with ultra-precision.

- Form grinding.

- Developed technology for precision componentsfor manufacturing with feature sizes in the range of <100 µm with stringent dimensional tolerances in the order of 5-10 µm on metallic and non-metallic parts indigenously. Such components have been regularly supplied to various capital goods and strategic sectors.

List of Relevant Publications

- K. Niranjan Reddy, and K. Chandran, “Development of Ultrasonic Standard Reference blocks of Aerospace Quality”, presented at QUEST-2001 conference, VSSC, Trivandrum.

- G. Jayaraman, V.K. Venkateswaran, and K. Niranjan Reddy, “An Analytical Approach for Precise Positioning of Tool in Diamond Turning”, European Society for Precision Engineering & Nanotechnology - euspen 2001 conference.

- K. Niranjan Reddy, and P.V. Shashi Kumar, “Micro-Drilling of Precision Flat Bottom Holes in Titanium”,presented atCOPEN 2003-04, CMTI, Bangalore.

- K. Niranjan Reddy, P.V. Shashi Kumar, and SomashekarRao, “Micro Finish & Micro EDM Applications in Precision manufacturing”,Manufacturing Technology Today Magazine January 2007 published by NICMAP, CMTI.

- K. Niranjan Reddy, and P.V. Shashi Kumar, “Centering of Tool in Diamond Turning”,presented at 21st AIMTDR, VIT, Vellore.

- V.R. Raju ,M.Chellamalai, P.V.Shashikumar “Study on surface quality and accuracy of hard turned axial feed rollers of honing machine”. - “Int. Journal of Precision Technology” by Inderscience Publishers, Vol. 3, No 1, 2012, 82-90.

- V.R. Raju , Srinivasa C.K ,Vinod A.R, “Study on micro-electrical discharge machining of Steel using copper Electrodes” -1st National Conference on Micro & Nano Fabrication” 2013, CMTI, Bangalore.

- Gopikrishna S, V. R. Raju ,Ankit K, Shashikumar P. V. , “Manufacture of micro sized thread for micro actuator of laser Grating mount”. - Int. Journal of Advanced manufacturing technology” by Springer Publishers, 09 May 2012.

- Karthik M S, Kuppuswamy Ramesh, Raju V.R., Manjunatha M A, Balashanmugam N, “Study on effect of abrasive flow polishing on wear characteristics of ball nose end mill” –COPEN 2019 @ IIT Indore.

- K. Niranjan Reddy*, T. Narendra Reddy, Shashi Kumar, V.R Raju, P.V Shashi Kumar , “Evaluation of Spiral Groove Depth on a Spherical Surface by usingCurve Fitting Algorithm” - International Colloquium on Material, Manufacturing and Metrology, ICMMM 2014 August 8-9, IIT Madras, Chennai, India.

- M.S. Karthik, V.R. Raju., K.Niranjan Reddy, N. Balashanmugam, M.R. Sankar, (2020) “Cutting parameters optimization for surface roughness during dry hard turning of EN 31 bearing steel using CBN Insert.” Materials today: proceedings; DOI:10.1016/j.matpr.2020.02.224

Technical Queries

Scientist - D

Centre for Micro-Nano Manufacturing and Metrology (C-MNTM)

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru – 560022

E-mail: rajuvr[at]cmti[dot]res[dot]in

Phone: +91-80-22188264

Scientist - C

Centre for Micro-Nano Manufacturing and Metrology (C-MNTM)

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru – 560022

E-Mail: karthik[at]cmti[dot]res[dot]in

Phone: +91-80-22188383

The Precision manufacturing and process engineering group develops machining technology indigenously in the area of micro machining and provides solutions for user industries. CMTI can also undertake feasibility studies or take up R&D for institutions working on technology development in the micromachining area.

For more details contact

Technology Transfer

Joint Director & Centre Head (C-MNTM)

Centre for Micro-Nano Manufacturing and Metrology (C-MNTM)

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru – 560022

Phone (Office): +91-80-22188379

Mobile: +91-9449842672

E-mail: niranjan[at]cmti[dot]res[dot]in

Precision Manufacturing & Process Engineering Group

Centre for Micro-Nano Manufacturing and Metrology (C-MNTM)

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru – 560022