- services

- Facilities

- Contact Us

=> NABL Certificate of Accrediation METROLOGY LABORATORY, CMTI

=> NABL Scope of Accrediation METROLOGY LABORATORY, CMTI

The Metrology Laboratory is a part of the Centre for Micro and Nano Manufacturing at CMTI. Metrology activities comprises of services to industry in measurement, calibration and testing and development of artefacts in metrology.

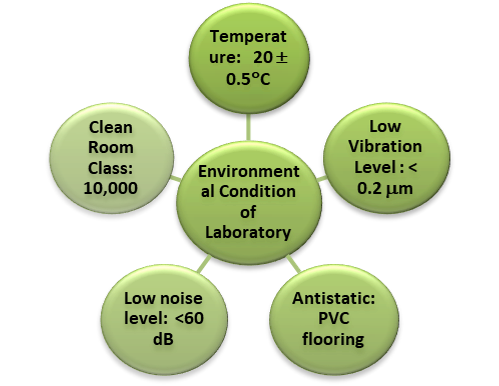

The Laboratory is housed in an environmentally controlled underground laboratory built to meet International standards, for high level metrology and calibration.

The Metrology Laboratory has been accredited in the field of dimensional

metrology by the National Accreditation Board for Testing and Calibration Laboratories (NABL) in accordance with ISO/ IEC 17025.

Amongst the services offered extensively by this laboratory are the following:

Calibration Services

Calibration of Reference Masters

Calibration of Reference Masters includes the calibration of Grade ‘K’ Gauge Blocks, Glass Hemisphere, Flick Standard, Master Cylinder, Optical Flat, Step Gauge, Roughness Masters, Master Sphere etc

Calibration of Gauges / Instruments:

Calibration of gauges includes setting Ring Gauges, Dial Gauges, Plug gauge, etc. and instruments include Verniers, Micrometers, Electronic Levels, etc.

Calibration of Measuring Equipment:

Calibration of Measuring Instrument at permanent facility as well as at site includes calibration of Coordinate Measuring Machine, Profile Projector, Universal Length Measuring Machine / Metroscope, Universal Measuring Microscope, Length Measuring Machine, Gear Testing Machine, Gauge Block Comparator, etc.

Inspection Services

The laboratory caters to precision measurement requirements of linear and angular dimensions, form, position, gear parameters and surface texture with traceability to national/international standards. Laboratory also takes up the on-site inspection of large parts using Portable Arm CMM and Laser Tracker system.

Laser Measurement Services

CMTI has been calibrating machine tools from the past three decades. We offer on-site calibration of conventional as well as CNC machinery and measuring equipment. Services include alignment of large machines like Roll Grinding Machines, Plano Millers and Floor type Boring Machines and Structures like Rails, Guide Tracks, etc. Our calibration and measurements are traceable to national and international standards. The services are accredited by NABL for on-site calibration of Machine Tools, CMMs and other measuring machines. Calibration can be carried out as per ISO, NMTBA, VDI-DGQ, JIS & CMMA standards

Dynamic Measurements and Analysis Using Laser Measurement System

Dynamic measurement and analysis is a solution for testing precision machine tools and measuring machines. The Laser laboratory is equipped with Laser Measurement Systems having higher data capture speeds (up to 5000 Hz), which are used for dynamic measurements like velocity and acceleration of slides, which reveal drive errors and stick slip motion. These systems can also be used for monitoring various machines elements for their performance.

Laser Measurement System for Alignment

The Laser Laboratory also offers services in the activity of Alignment using Laser Measurement/ Alignment System. Alignment of the machine prior to calibration is necessary before starting the calibration exercise. The services include alignment of guide ways, guide rails, bores, guide tracks, etc. CMTI has developed the expertise to monitor various parameters during and after levelling and alignment exercise. The laboratory possesses Laser Measuring Systems, Laser Alignment System, Electronic Levels, Auto Collimators, Rotary Calibrator, Alignment Telescope, etc. to assist in the above work.

Calibration of Laser Measuring System

The Laser Laboratory maintains a Reference Laser Measurement System with traceability to International Standards as a Master. Using this system, other Laser Measurement Systems are calibrated by comparison. The calibration covers the overall accuracy of the system along with accuracies of Laser head and Sensors.

Ball Bar System

Ball Bar System with its software is used to measure geometrical errors present in the CNC machines and detect inaccuracies induced by its controller and servo drive systems. It can measure the inaccuracies like reversal error, straight-ness of slides movement, relative squareness of axes, lateral play in the axis, positioning accuracy, reversal spike, servo system lag and lead error, etc.

CMTI’s Customer Profile

Presently over 100 machines are calibrated annually at sites and services spread all over India. The customer profile is very vast and includes machine tool manufacturers, suppliers and user industries including automobile and earth moving machine manufacturing industry, aircraft manufacturers, paper industry and electronic product manufacturers. With a team of calibration experts and support of state of the art instruments, CMTI can offer these services to overseas clients also.

CMTI has state of art facilities in Precision Metrology Laboratory. To know more about the facilities please contact us.

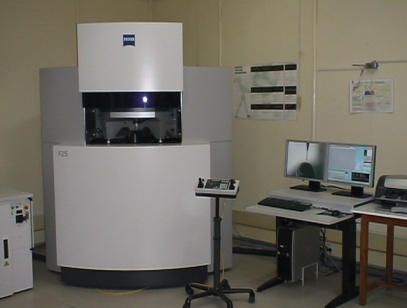

Range: X: 850 mm, Y: 1200 mm, Z:600 mm

Resolution : 0.1 µm

Size Measuring uncertainty MPEE : (1.7+ L/300) µm

Measurement of the dimensions of 3D components & Surfaces

Range: X: 130 mm, Y: 130 mm, Z:100 mm

Resolution : 1 nm

Size Measuring uncertainty MPEE : (0.5+ L/666) µm

Measurement of the dimensions of 3D micro-components & micro-features

Range: up to 300mm

Resolution: 1 nm

Repeatability : 5 nm

Calibration of Grade ‘K’ Slip Gauges

Sample size :100 mm

Resolution : λ/8000 mm

Laser wavelength: λ = 632.8 nm

Sample reflectivity: 0.1-100%

Calibration of flatness of the surface, Optical Flats, Parallels

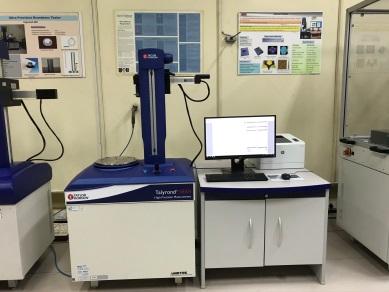

Measuring Range:Length : 500 mm,

Diameter : 400 mm

Resolution : 0.3 nm

Spindle rotational accuracy : 10 nm

Straightness of arm: 0.3 mm

Measurement of form features like Straightness, Circularity, Cylindricity etc, Calibration of Form Masters

Pickup Range- 15 mm

Traverse Length: 200mm

Resolution: 0.3 nm

Measurement of Roughness Parameters like Ra, Rt etc, Calibration of Surface Roughness, Depth Masters etc.

Range- 680 mm

Resolution : 10 nm

Calibration of Gauges

Measurement Range- 100 mm

Resolution: 1 nm

Repeatability: 5 nm

Calibration of Gauge Blocks

Measurement Range- Diameter: 640mm

Resolution : 1µm

Module: 0.1 to 20

Outside Dia : 4-640 mm

Base circle diameter: 3-600 mm

Base helix angle: 0-65°

Calibration of Profile & Lead Masters, Master Gears and Inspection of Gears

Measurement Range- Diameter: 2.5 m

Resolution : 0.1µm

No. of Axes: 6 + 1

Maximum Permissible Error EUni, MPE : 0.031 µm

Inspection of Large Components and Reverse Enginnering

Measurement Range: 80 m

Resolution : 1nm

Accuracy : ± 1 ppm

Calibration of CNC Machine Tools, CMMs, Measuring Equipment etc.

Measurement Range: 360 deg

Resolution : 0.04 arc sec

Accuracy : ± 1 arc sec

Applications:

Calibration of Rotary/ Index Tables

Measuring range : ± 1 mm

Resolution : 0.1 μm

Accuracy : ± (0.7 + 0.3% L) μm

(L is Measured Length in mm)

Applications

Calibration of CNC Machine Tools for Circular Test

Working Volume (ø): 320 m

Resolution: 1µm

Accuracy : ± (15 μm + 6 μm/m)

Inspection of Large Parts, Alignment of Fixtures

Joint Director & Centre Head (C-MNTM)

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru-560022

Phone (office): +91-80-22188379

Mobile: +91-9449842672

Fax: +91-80-23370428

E-mail: niranjan[at]cmti[dot]res[dot]in

Mrs. Khushboo/ Mr. Shashi Kumar

metrologylab[at]cmti[dot]res[dot]in

Phone: +91-80-22188392

Inspection Services

Mrs. Khushboo/ Mr. Siddaraju

inspectionlab[at]cmti[dot]res[dot]in

Phone: +91-80-22188258, 392

Laser Measurement Services

Mrs. Khushboo/ Mr. Rammohan

laserlab[at]cmti[dot]res[dot]in

Phone: +91-80-22188381

Precision Metrology Group

Centre for Micro-Nano Manufacturing and Metrology (C-MNTM)

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru – 560022