- project

Completed Projects

IOT Enabled “SMART” Metal Cutting Machine -empowering a Legacy Machine @CMTI

Smart features

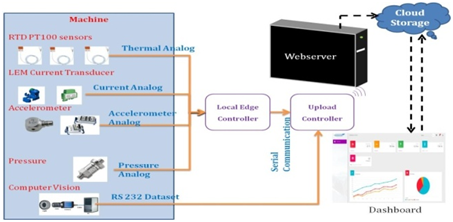

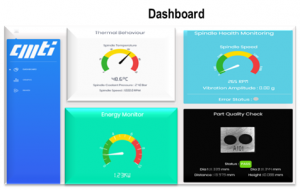

Sensor modules

- Temperature : Machine thermal plot

- Vibration : Machine health

- Evaluate TcP(tool center point) drift

- Pressure : Spindle coolant pressure

- Energy : Downtime of the machine

- Vision : In-situ inspection / Quality

Outcome

- Generate diagnosis reports / action plan

- Classify reports based on severity

- Enable deep dive information for better process understanding

- Establish data base for further analytics

Outputs

- IOT enabled connected machine

- Remote access of machine health and process data

- Real time Machine health monitoring

- Energy monitoring

- Better process monitoring

- Reduced machine down time

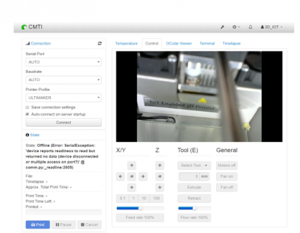

Implementation: For the Demonstration of IOT Enabled Additive Manufacturing

A IOT enabled Control GUI has been developed to control the 3D printer in a closed loop. The following features have been implemented.

- Cloud based 3D printing by uploading G-code via Any internet connected device, i.e Mobile Phones & Tablets.

- Cloud based closed loop monitoring of process parameters & Temperature signatures of subsystems of 3D printer.

- A complete live fabrication process can be viewed online via IOT process monitoring camera.

Ongoing Projects

Development of indigenous IIoT Solutions

Objective:

- Development of Production monitoring, Diagnostics and Condition

- Development of a Dashboard for Overall Equipment Efficiency

- Development of Low Cost Energy Monitoring IIOT Solution for Smart Factory

- Development of a compressive machine tool health condition monitoring module

- Development of Supervisor login and OEE dashboard

Outcome:

- Low cost IIoT Solutions for MSME’s

Smart Factory Demonstration

Objective:

- Establishment of Smart Factory Demonstration Cell at CMTI

Deliverables:

- Smart Factory Demonstration Cell at CMTI

Development of Production monitoring, Diagnostics and Condition Monitoring modules for machine tools

Objective:

- Development of IIOT solutions for Production Monitoring and OEE for Machine tool centric industries.

- Development of Diagnostics and Condition Monitoring module for machine tools.

Deliverables:

- IoT enabled vibration, temperature, force and pressure monitoring.

- Live Health Monitoring of Machines/Machine Tool Subsystem/Machine elements.

- Machine Health Trending and Analytics

- Technology Development, IP Creation

- Indigenous development of smart OEE & diagnostics module. Zero Breakdown, productivity improvement Prediction of impending problems.

Design and Development of Smart Precision Integrated Motor Spindle

Objective:

- Design and development of integrated motor spindle with in-built industry 4.0 features for machine tool application like HMC, VMC, ultra-precision machines

Deliverables:

- Smart spindles for High Precision HMC and VMC Machines.

- Integrated motor spindle with built in intelligent feature for building future smart machines.

- Technology Development, IP Creation

- Indigenous development and marketing

- Import Substitution

Digital Twin based Availability prediction for Spindle & Feed drive system of Machine tools

Objective:

- Development of Digital Twin based Availability Prediction for Spindle and Feed Drive systems of Machine Tools.

Outcome:

- Technology Development, IP Creation

- Smart Diagnosis and Prognosis Module of spindle and feed drive systems,

- Smart Inventory Management, Digital Twin based Production Availability Module, Production analytics Module

Establishment & Demonstration of Smart Factory with Digital Twin

Objective:

- To Establish and Demonstrate Smart factory and its digital twin for manufacturing industries

- To offer smart manufacturing solutions to industries

Outcome:

- To encourage SME’s. MSME’s to implement smart manufacturing technologies.

- Hands on experience and demonstration of smart manufacturing technology.

- Training of SME’s and MSME’s workforce.