- Project

- Services

| S. No. | Name & Specifications | Photo |

|---|---|---|

| 1 |

High Speed Shuttleless Rapier Loom (LR-450)

|

|

| 2 |

Single Head Centreless Bar Turning Machine (TBC – 36)

|

|

| 3 |

Twin Head Centre-less Bar Turning Machine (TBCDH – 36)

|

|

| 4 |

Diamond Turning Machine

|

|

| 5 |

Multi Gauging System

|

|

| 6 |

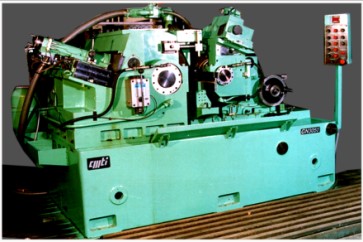

Centre less Grinding Machine (GN-3050)

|

|

| 7 |

Engraving Machine

|

|

| 8 |

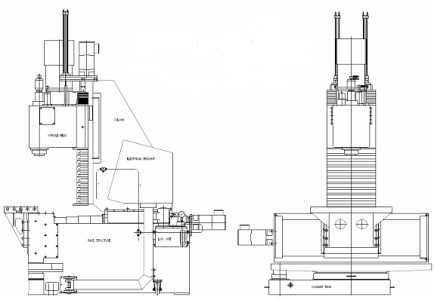

Goliath Facing & Taper Boring Machine

|

|

| 9 |

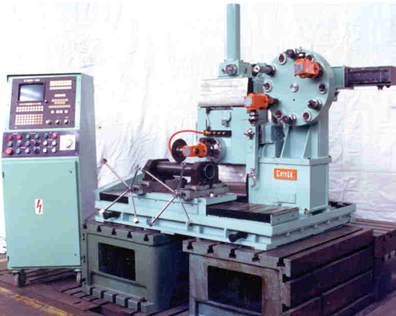

CNC Piston Ring Finish Turning and Grooving Machine

|

|

| 10 |

Facing and Boring Machine (FB-50)

|

|

| 11 |

Line Boring Machine (LBM)

|

|

| 12 |

CNC Keystone Piston Ring Grinding Machine (GKPR-CNC)

|

|

| 13 |

CNC Vertical Milling Machine

|

|

| 14 |

CNC Specimen Cutting Machine

|

|

| 15 |

Universal Cylindrical Grinding Machine (UGC-260)

|

|

Integrated Manufacturing Services

CAD/CAM

- CAD/CAM services in NX12/NX7.5 and Hypermill2019.2.

- CNC program generation for precision components and assemblies

- Interface between Process planning and CNC part programming

- Interface between process planning and operation Layout creation

- Jigs & Fixture design solutions

Manufacturing R&D

- Development of technology for novel materials etc.

- Solving complex manufacturing problems of Industry

- Methods Study

- Non-traditional machining like Die-sinking EDM and wire-cut EDM Laser machining

- Research streams from ongoing projects to facilitate PG projects for the academic fraternity.

- Re-conditioning of critical machine tool elements.

Manufacturing Planning Applications

- Selection of machine tools and manufacturing systems

- Technology Auditing and Productivity improvements

- Training programs in CAD/CAM NX-12 and NX-7.5 and training programs in manual part programming

- Preparation of Detailed Project report for product manufacture

- Process Planning and Time Estimation for Components

- Development of Machining Data Bank