- Services

- Facilities

- Contact Us

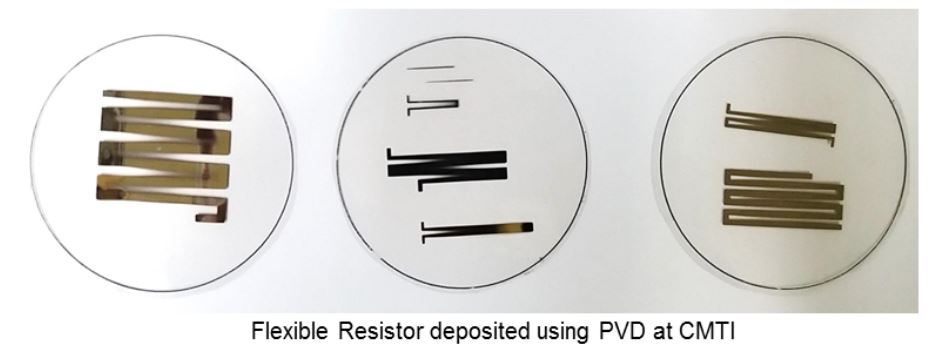

The Surface Engineering group focuses particularly in the development of thin films. The group provides deposition services for industries and academia

Deposition and R&D Services

The Surface Engineering group offers highly customised services which include not only deposition but also outsourced R&D for client applications. We can offer consultancy services based on the applications. Services that we offer in thin film coatings:

Service and Description

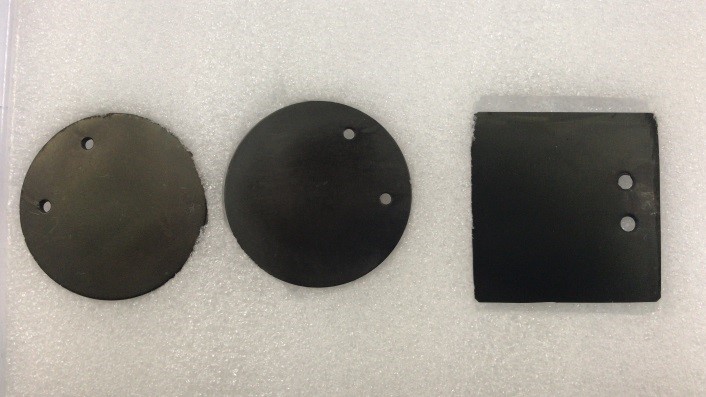

Deposition of Diamond Like Carbon on various substrates

We can deposit DLC films over a wide variety of substrates. We initially start with a feasibility of deposition with minor trial R&D on a substrate provided to us and provide deposition on client’s substrates. DLC films provide very hard coating and have anti scratch and anti wear properties. We can deposit DLC on plastics, metals, glass etc.

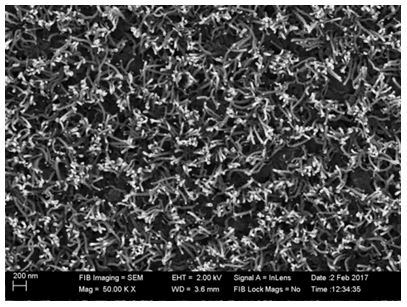

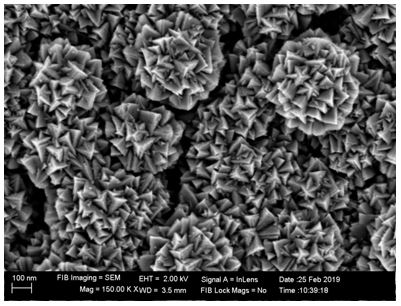

Deposition of Carbon Nano Tubes on substrates

We can deposit films of CNTs on Stainless Steels, Inconel, Silicon, Anodised Titanium, Anodised Aluminium and Titanium. For additional materials contact us for details.CNT films offer super black coating and also are excellent for sensing applications. We can also couple other metals or non-metals with CNTs for tailor made applications

Metal Deposition

We can deposit metals for various applications like sensing, protection, catalyst or bond layer etc.

We take up industrial projects as well.

Please contact us for further details on the same.

Vacuum chamber Size: 500 × 500 × 500 mm

Coating area: Dia 250 mm

Base Vacuum : 1 × 10-7 mbar

Plasma source : ECR Microwave & RF

Process Gases : C2H2, CH4,N2, Ar, O2, H2, NH3

Substrate Heater : 700° C

Carbon Nanotubes and Diamond Like Carbon Films

Vacuum chamber Size: D-Type 500 mm

Coating area: 3 x 3” target and 1 x 6” Target with substrate rotation

Target sizes: Maximum 6”

Plasma Sources: RF, DC and Pulsed DC

Base Vacuum : 1 × 10-7 mbar

Process Gases N2, Ar, O2,

Substrate Heater : 600° C

Metal, Metal Oxide and Metal Nitride Depositions

Effective Drop : 2 µL

Video : 100 fps

Measurement : Only flat samples kept on horizontal table

Temperature : Room

Vacuum : Atmospheric

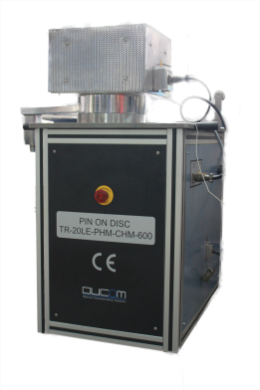

Contact for Ball and Pin Sizes

Contact Angle Measurement

Disk Dia : 6 inch

Load : 5-100 N

RPM : Upto 1500

Temperature : Room

Vacuum : Atmospheric

Contact for Ball and Pin Sizes

Measurement of Co-efficient of Friction

Cost of Services

We offer the utilisation of our laboratory services for both deposition using PVD and CVD along with characterisation. The facilities list consists of all the specifications of the equipment that are available for services.

Please contact us if you have any queries for customised solutions.

| Sl No. | Facility | Charges in Rupees/Hour | |

| Industry | Academia | ||

| 1 | Magnetron Sputtering Physical Vapour Deposition | 4100 | 2600 |

| 2 | Plasma Enhanced Chemical Vapour Deposition | 5900 | 4000 |

| 3 | Contact Angle Measurement | 2000 | 1300 |

| 4 | Pin On Disk Tribometer | 1800 | 1200 |

*The rates of the services shall be changed periodically. Specific consumables will be charged extra on actuals. Please contact us for exact prices. Cost of the equipment is based on the usage on a per hourly basis. 18% GST Extra.

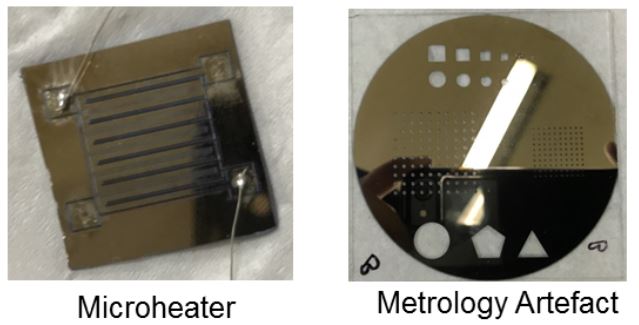

Technologies Ready for Transfer

The following technologies are available for technology transfer:

- Synthesis of Room Temperature Diamond Like Carbon on any surface with high hardness >2500 HV

- MIL – C Standard qualified DLC films for Infra Red Windows for Anti Reflection and Night Vision Application

- Diamond Like Carbon for functional and aesthetic surfaces

- Carbon Nanotube direct deposition on aerospace materials

- Super Black Carbon Nanotubes for space applications

Technical Queries

Mr. Sunil Magadum

Scientist – D

Group Head for Micro-Nano Manufacturing

Centre for Micro-Nano Manufacturing and Metrology (C-MNTM)

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru – 560022

Phone: +91-80-22188391

E-Mail: sunilm[at]cmti[dot]res[dot]in

Mr. K. Niranjan Reddy

Joint Director & Centre Head (C-MNTM)

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru-560022

Phone (Office): +91-80-22188379

Mobile: +91-9449842672

Fax: +91-80-23370428

E-mail: niranjan[at]cmti[dot]res[dot]in

Technology Transfer

CMTI can also undertake feasibility studies or take up R&D for institutions working on technology development of such advanced work.

For more details contact

Mr. K. Niranjan Reddy

Joint Director & Centre Head (C-MNTM)

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru-560022

Phone (Office): +91-80-22188379

Mobile: +91-9449842672

Fax: +91-80-23370428

E-mail: niranjan[at]cmti[dot]res[dot]in

Surface Engineering & Laser Processing Group

Centre for Micro-Nano Manufacturing and Metrology (C-MNTM)

CMTI, Tumkur Road, Bangalore – 560022