- Introduction

- People

- Research Areas

- Projects

- Services

- Facilities

- Achievements

- Gallery

- Contact

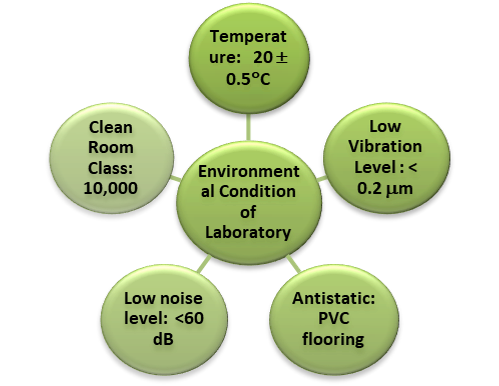

The Centre for Micro - Nano Manufacturing and Metrology focuses on services and research & development of high precision components for industrial requirements. In CMTI, work on precision engineering started in the year 1992 and in 1997 an underground building was constructed specifically for the purpose to promote the Precision engineering in the country. The building is one of its kind which had a class 1,00,000 for precision machining and an underground metrology lab with class 10,000 housed 6m below the ground with monolithic anti vibration concrete blocks maintained at 20°±0.5°C and vibration level < 0.2 µm. The department includes metrology laboratory for dimensional metrology with state of art equipments and accredited by NABL.

Presently, the C-MNTM takes up projects sponsored by Indian Industries, Industry consortiums and Government funded R&D and fabrication of high precision miniaturized micro and nano components having feature sizes in the order of less than one millimetre. Micro manufacturing is one of the emerging areas and CMTI has well established the facility to meet the requirement of Indian Industry.

Precision Metrology Group

The Metrology Laboratory is a part of the Centre for Micro and Nano Manufacturing at CMTI. Metrology activities comprises of services to industry in measurement, calibration and testing, development of measuring instruments and artefacts in metrology.

The Laboratory is housed in an environmentally controlled underground laboratory built to meet International standards, for high level metrology and calibration.

The Metrology Laboratory has been accredited in the field of dimensional metrology by the National Accreditation Board for Testing and Calibration Laboratories (NABL) in accordance with ISO/ IEC 17025.

| Centre Head | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

|

Mr. Niranjanreddy K | Joint Director | View Profile |

| Group Head | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

| Scientists | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

|

Mrs. Khushboo | Scientist - D | View Profile |

|

Mr. K Manjunath | Scientist - B | View Profile |

|

Dr. Abhinav Kumar | Scientist - B | View Profile |

|

Dr. Debeshi Dutta | Scientist - C | View Profile |

| Technical Staff | |||

| Photo | Name | Designation | Phone (Office) |

|---|---|---|---|

|

Mr. Shashi kumar | Senior Technical Assistant - II | 080-22188392 |

|

Mr. Rama Mohan P | Senior Technical Assistant I | 080-22188381 |

|

Mr. Siddaraju K G | Senior Technical Assistant - I | 080-22188258 |

|

Mr. Shivaraju C T | Senior Technical Assistant - I | 080-22188381 |

|

Mr. Rudramurthi M M | Senior Technical Assistant - I | 080-22188389 |

|

Mr. Chethan H S | Technical Assistant | 080-22188381 |

|

Mr. Pramod D S | Technical Assistant | 080-22188258 |

|

Mr. Rangaswamy B L | Technical Assistant | 080-22188389 |

|

Mr. Kirankumar M D | Technical Assistant GR II | 080-22188389 |

|

Mr. Sadashiva D | Technical Assistant | 080-22188389 |

|

Mr. Harikrishna H V | Technician III | 080-22188389 |

|

Mr. Manjunatha K | Technician III | 080-22188258 |

| Administration | |||

| Photo | Name | Designation | Phone (Office) |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

- Development of Automated Inspection Systems

- Development of metrology artefacts

- Gauging systems development

Artefact development

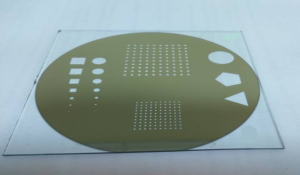

The measuring instruments are qualified for their accuracy by using metrology artefacts. This metrology artefacts establishes the traceability of measurements. CMTI developed Metrology artefacts like Master Spheres, Master Cylinders, Calibration Mask and Standard Glass Scales which are used for performance evaluation of measuring equipment.

CMTI developed Reference blocks for calibration of flaw detectors used in Non Destructive Testing (NDT). These reference blocks are made with precisely drilled flat bottom holes (FBH) of different diameters depending on the allowable level of flaws. Reference blocks with flat bottom holes of dia from 2 mm down to dia 0.5 mm are mainly used in aerospace applications.

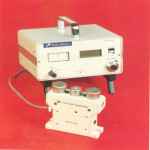

Automated Inspection System Developed by CMTI with Auto-correction feed back

The system was developed for comparing the manufactured part dimensions with designed dimensions and records the deviations with indication of component acceptance, rejection or needs rework.

Highlights of developed Multi gauging systems:

- Automatic gauging significantly cuts down the inspection time

- Eliminates human measurement error

- Measured data is stored and accessed from the PC for statistical analysis.

- Online correction for the dimensional variation by automatically feeding the result of inspection to CNC system

Software development for Surface flatness evaluation

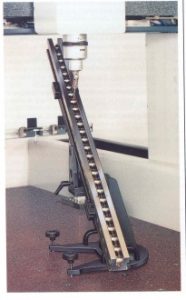

CMTI has developed software for flatness evaluation known as CSurFlat. This software evaluates flatness of the working surface overall and also flatness of any local area as recommended in IS 2285 : 2003 / IS 7327 : 2003. Supports grid pattern calibration method as per IS 12937 : 1990. Evaluates flatness error by generating a regression plane determined by Least Square fit.

The features of software are listed below.

- Windows based and user friendly, runs on Win-2000 / XP

- CSurFlat is stand-alone as it uses built-in Data Base Management System

- Flatness evaluation on the fly

- Reports include evaluation details, table(s) of readings, deviation and deviation plot

- Other Developments

CMTI developed various metrological products like Granite surface plates with accuracy to Grade-0 of IS:7327-2003, Precision dial indicators working on principle of twisted band for reliable and accurate application, electronic comparators with resolutions down to 0.5 micron, bore gauges, spherometer to measure the radius of curvature, in-process gauging systems for the grinding operation, tool pre-setters for measurement of tool length and diameter etc.

Amongst the services offered extensively by this laboratory are the following:

Calibration Services

Calibration of Reference Masters

Calibration of Reference Masters includes the calibration of Grade ‘K’ Gauge Blocks, Glass Hemisphere, Flick Standard, Master Cylinder, Optical Flat, Step Gauge, Roughness Masters, Master Sphere etc

Calibration of Gauges / Instruments:

Calibration of gauges includes setting Ring Gauges, Dial Gauges, Plug gauge, etc. and instruments include Verniers, Micrometers, Electronic Levels, etc.

Calibration of Measuring Equipment:

Calibration of Measuring Instrument at permanent facility as well as at site includes calibration of Coordinate Measuring Machine, Profile Projector, Universal Length Measuring Machine / Metroscope, Universal Measuring Microscope, Length Measuring Machine, Gear Testing Machine, Gauge Block Comparator, etc.

Inspection Services

The laboratory caters to precision measurement requirements of linear and angular dimensions, form, position, gear parameters and surface texture with traceability to national/international standards. Laboratory also takes up the on-site inspection of large parts using Portable Arm CMM and Laser Tracker system.

Laser Measurement Services

CMTI has been calibrating machine tools from the past three decades. We offer on-site calibration of conventional as well as CNC machinery and measuring equipment. Services include alignment of large machines like Roll Grinding Machines, Plano Millers and Floor type Boring Machines and Structures like Rails, Guide Tracks, etc. Our calibration and measurements are traceable to national and international standards. The services are accredited by NABL for on-site calibration of Machine Tools, CMMs and other measuring machines. Calibration can be carried out as per ISO, NMTBA, VDI-DGQ, JIS & CMMA standards

Dynamic Measurements and Analysis Using Laser Measurement System

Dynamic measurement and analysis is a solution for testing precision machine tools and measuring machines. The Laser laboratory is equipped with Laser Measurement Systems having higher data capture speeds (up to 5000 Hz), which are used for dynamic measurements like velocity and acceleration of slides, which reveal drive errors and stick slip motion. These systems can also be used for monitoring various machines elements for their performance.

Laser Measurement System for Alignment

The Laser Laboratory also offers services in the activity of Alignment using Laser Measurement/ Alignment System. Alignment of the machine prior to calibration is necessary before starting the calibration exercise. The services include alignment of guide ways, guide rails, bores, guide tracks, etc. CMTI has developed the expertise to monitor various parameters during and after levelling and alignment exercise. The laboratory possesses Laser Measuring Systems, Laser Alignment System, Electronic Levels, Auto Collimators, Rotary Calibrator, Alignment Telescope, etc. to assist in the above work.

Calibration of Laser Measuring System

The Laser Laboratory maintains a Reference Laser Measurement System with traceability to International Standards as a Master. Using this system, other Laser Measurement Systems are calibrated by comparison. The calibration covers the overall accuracy of the system along with accuracies of Laser head and Sensors.

Ball Bar System

Ball Bar System with its software is used to measure geometrical errors present in the CNC machines and detect inaccuracies induced by its controller and servo drive systems. It can measure the inaccuracies like reversal error, straight-ness of slides movement, relative squareness of axes, lateral play in the axis, positioning accuracy, reversal spike, servo system lag and lead error, etc.

CMTI’s Customer Profile

Presently over 100 machines are calibrated annually at sites and services spread all over India. The customer profile is very vast and includes machine tool manufacturers, suppliers and user industries including automobile and earth moving machine manufacturing industry, aircraft manufacturers, paper industry and electronic product manufacturers. With a team of calibration experts and support of state of the art instruments, CMTI can offer these services to overseas clients also.

CMTI has state of art facilities in Precision Metrology Laboratory. To know more about the facilities please contact us.

Range: X: 850 mm, Y: 1200 mm, Z:600 mm

Resolution : 0.1 µm

Size Measuring uncertainty MPEE : (1.7+ L/300) µm

Measurement of the dimensions of 3D components & Surfaces

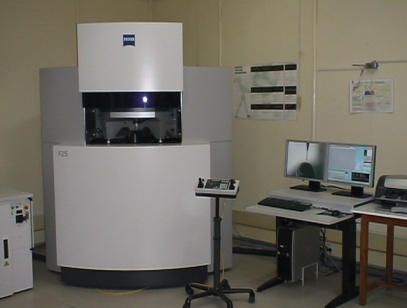

Range: X: 130 mm, Y: 130 mm, Z:100 mm

Resolution : 1 nm

Size Measuring uncertainty MPEE : (0.5+ L/666) µm

Measurement of the dimensions of 3D micro-components & micro-features

Range: up to 300mm

Resolution: 1 nm

Repeatability : 5 nm

Calibration of Grade ‘K’ Slip Gauges

Sample size :100 mm

Resolution : λ/8000 mm

Laser wavelength: λ = 632.8 nm

Sample reflectivity: 0.1-100%

Calibration of flatness of the surface, Optical Flats, Parallels

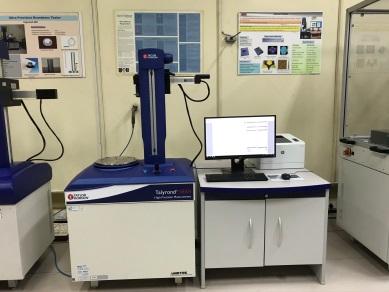

Measuring Range:Length : 500 mm,

Diameter : 400 mm

Resolution : 0.3 nm

Spindle rotational accuracy : 10 nm

Straightness of arm: 0.3 mm

Measurement of form features like Straightness, Circularity, Cylindricity etc, Calibration of Form Masters

Pickup Range- 15 mm

Traverse Length: 200mm

Resolution: 0.3 nm

Measurement of Roughness Parameters like Ra, Rt etc, Calibration of Surface Roughness, Depth Masters etc.

Range- 680 mm

Resolution : 10 nm

Calibration of Gauges

Measurement Range- 100 mm

Resolution: 1 nm

Repeatability: 5 nm

Calibration of Gauge Blocks

Measurement Range- Diameter: 640mm

Resolution : 1µm

Module: 0.1 to 20

Outside Dia : 4-640 mm

Base circle diameter: 3-600 mm

Base helix angle: 0-65°

Calibration of Profile & Lead Masters, Master Gears and Inspection of Gears

Measurement Range- Diameter: 2.5 m

Resolution : 0.1µm

No. of Axes: 6 + 1

Maximum Permissible Error EUni, MPE : 0.031 µm

Inspection of Large Components and Reverse Enginnering

Measurement Range: 80 m

Resolution : 1nm

Accuracy : ± 1 ppm

Calibration of CNC Machine Tools, CMMs, Measuring Equipment etc.

Measurement Range: 360 deg

Resolution : 0.04 arc sec

Accuracy : ± 1 arc sec

Applications:

Calibration of Rotary/ Index Tables

Measuring range : ± 1 mm

Resolution : 0.1 μm

Accuracy : ± (0.7 + 0.3% L) μm

(L is Measured Length in mm)

Applications

Calibration of CNC Machine Tools for Circular Test

Working Volume (ø): 320 m

Resolution: 1µm

Accuracy : ± (15 μm + 6 μm/m)

Inspection of Large Parts, Alignment of Fixtures

Technologies/Products Developed

- Metrology artefact development like Master sphere, Reference blocks etc

- Development of Surface Plates

- Software development for the evaluation of surface flatness

- Development of automated inspection system

List of Relevant Publications

- K. Niranjan Reddy, H.K. Mallappa, and P.V. Shashi Kumar, “Development of Measurement Methodology by comparative methods for achieving best measurement capability on Ultra Precision CMM’s”, presented at AdMet 2009, NPL India, New Delhi.

- K. Niranjan Reddy, Nithin Narayanan, P.V. Shashi Kumar, and Sudhakar C Jambagi, “Establishment of Scanning Points for a Scanning Feature using Ultra Precision CMM”, presented at AdMet 2011, CMTI, Bangalore.

- K. Niranjan Reddy, Shanmugaraj V., Balashanmugam N., and Shashikumar P. V., “In-situ measurement of Straightness high aspect ratio thick walled cylinder – A concept”, presented at AdMet 2011, CMTI, Bangalore.

- Hari Prasath K, K. Niranjan Reddy, T. Narendra Reddy, and P.V Shashi Kumar, “Characterisation of Nano Finished Surfaces”, COPEN-7: 2011, presented at College of Engineering, Pune (COEP).

- K. Niranjan Reddy, T. Narendra Reddy, Shashi Kumar, V.R Raju, and P.V. Shashikumar, “Evaluation of Spiral Groove Depth on a Spherical Surface by using Curve Fitting Algorithm”, presented at ICMMM 2014, IIT Madras, Chennai.

- Murugan, K. Niranjan Reddy, H. K. Mallappa, Khushboo, and Shashikumar, “Effect of Change in Acceleration of Gravity in Accuracy of Electronic Levels”, presented at Admet 2016, NPL New Delhi.

- Mallappa H.K, Siddaraju K.G, K. Niranjan Reddy, and Khushboo, “New Approach in Calibration of Tilt Tables using Coordinate Metrology”, presented at Admet 2016, NPL New Delhi.

- Ankit.K, Sunil. M, K. Niranjan Reddy, N. Balashanmugam, “Development of Nanometre Edge Resolution Metrology Standards for Video Measuring Systems” Proceedings -Abstract at Advances in Metrology, 2019, National Physical Laboratory, New Delhi

- Sunil. M, Ankit.K, K. Niranjan Reddy, N. Balashanmugam “Process for the Development of high precision gratings/scales” selected at Advances in Metrology, 2019, Proceedings -Abstract at Advances in Metrology, 2019, National Physical Laboratory, New Delhi

Joint Director & Centre Head (C-MNTM)

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru-560022

Phone (office): +91-80-22188379

Mobile: +91-9449842672

Fax: +91-80-23370428

E-mail: niranjan[at]cmti[dot]res[dot]in

Mrs. Khushboo/ Mr. Shashi Kumar

metrologylab[at]cmti[dot]res[dot]in

Phone: +91-80-22188392

Inspection Services

Mrs. Khushboo/ Mr. Siddaraju

inspectionlab[at]cmti[dot]res[dot]in

Phone: +91-80-22188258, 392

Laser Measurement Services

Mrs. Khushboo/ Mr. Rammohan

laserlab[at]cmti[dot]res[dot]in

Phone: +91-80-22188381

Precision Metrology Group

Centre for Micro-Nano Manufacturing and Metrology (C-MNTM)

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru – 560022