- Introduction

- People

- Research Areas

- Projects

- Services

- Facilities

- Achievements

- Gallery

- Contact

Advanced Material and Characterisation

In this world of miniaturization, R&D in nanotechnology is getting better with the development of newer, faster, simpler and more efficient nanocharacterisation techniques.

Central Manufacturing Technology Institute (CMTI) has established centralized cutting edge nanocharacterisation, nano fabrication and nano metrology facility at the Centre for Smart Manufacturing, Precision Machine Tools & Aggregates, C-SMPM, open to all researchers.

Advance Material Characterisation lab under the Centre for Smart Manufacturing, Precision Machine Tools & Aggregates, C-SMPM, houses an array of state-of-the-art national facilities for materials characterisation. These services have been widely used by the industries, the academia & the scientists from R&D organizations apart from meeting in house R&D and characterisation requirements.

Advance material characterisation group also focuses on Equipment development for nano metrology and characterisation.

The group consists of experienced and highly dedicated scientists, professionals, technocrats and other well-known persons in the field.

Our Services:

Apart from the services, customized and innovative analysis can also be provided to ensure improved process, increase in productivity, quality control and compliance.

The following are the activities carried out by the group in the past to reveal the role of the laboratory in the field of research and development of new material or new process in various fields.

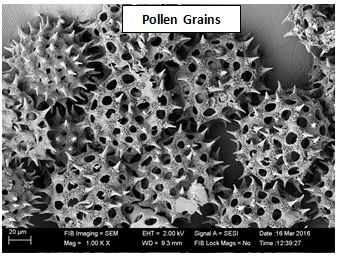

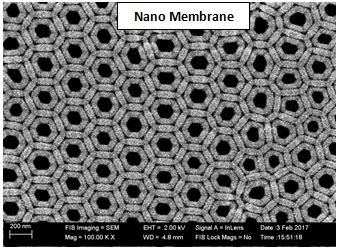

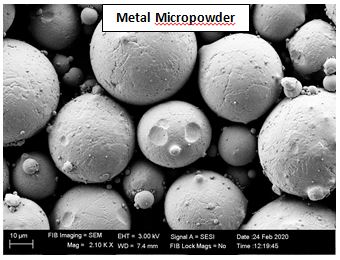

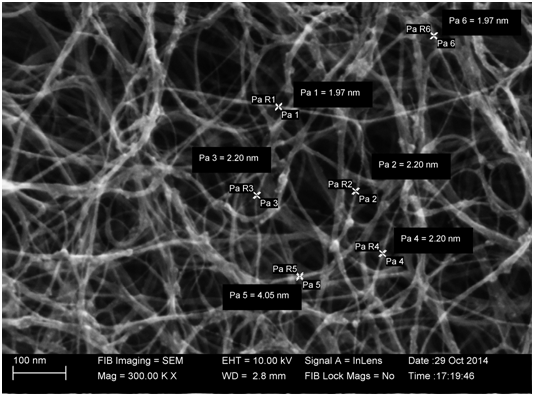

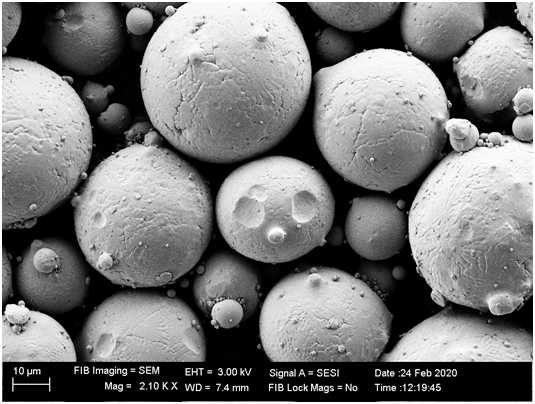

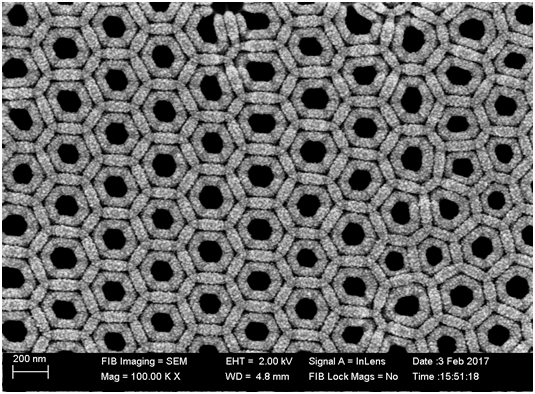

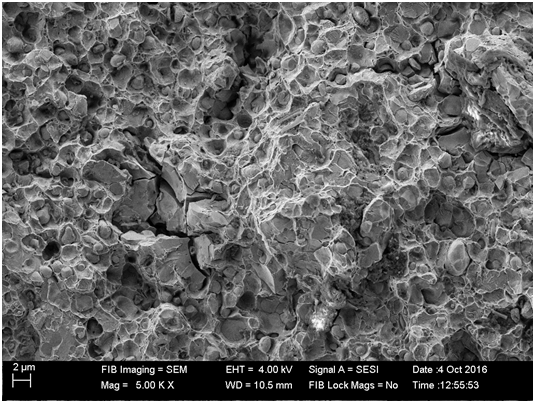

- High resolution imaging using Field Emission Scanning Electron Microscopy/ Focused Ion Beam (FESEM / FIB) in micro and nano scales for surface morphology and topography of the new material developed.

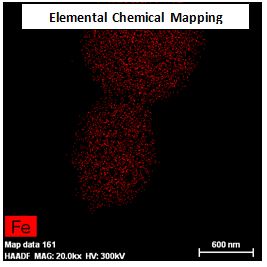

- Chemical composition analysis and elemental mapping using EDX for determining the material composition, quality check and failure analysis.

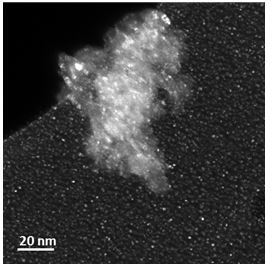

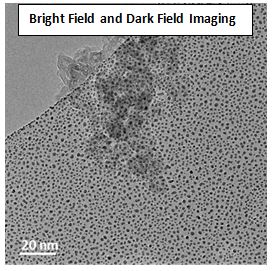

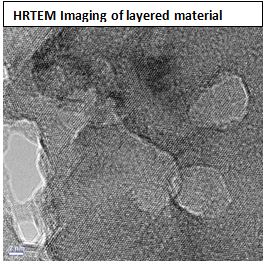

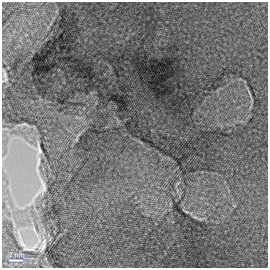

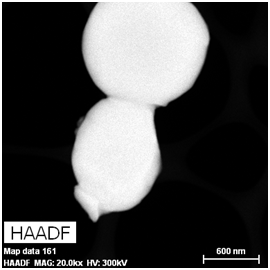

- Atomic scale imaging and crystallographic studies on the materials used for new product development using HRTEM.

- Identification of crystalline phases, Determination of Unit cell dimensions, Residual stress measurement, Retained Austenite etc., using X-Ray Diffraction

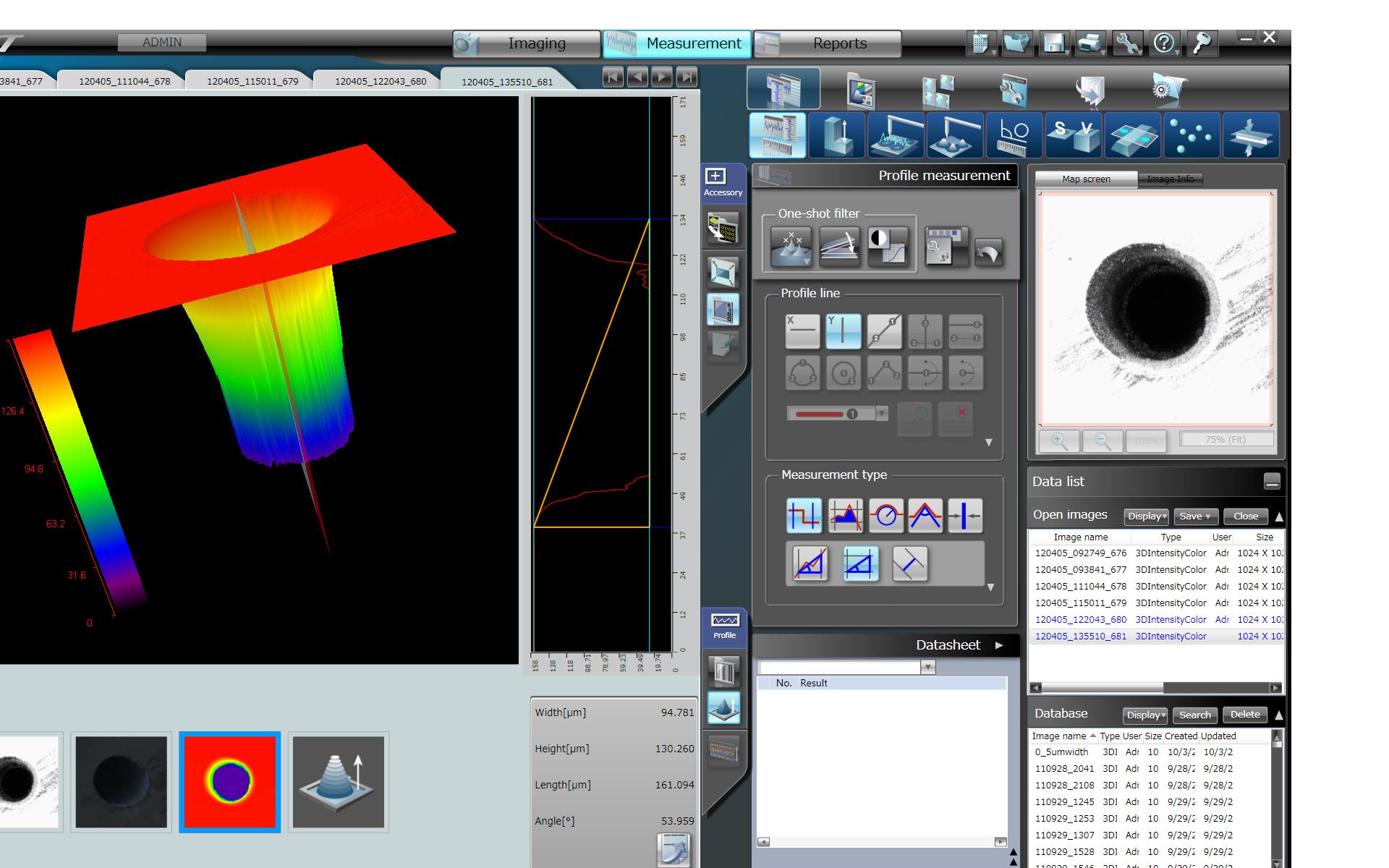

- Analysis of microscopic phase distribution, surface roughness, 3D topography using the scanning probe microscopy.

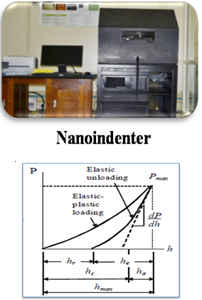

- Mechanical Characterisation like hardness, elastic modulus, friction coefficient, adhesion test and fracture toughness of thin films and coatings using Nanoindentor.

- Specific surface area of the materials with micro pore and meso pore measurements using surface area analyser.

- Composition of material, phase identification, stress/strain, quantitative analysis of amount of material and phase transition of material using RAMAN Spectroscopy.

- Analysis of the bonding signature, functional groups and composition of the materials using FTIR analysis.

- Grinding of brittle - Fibrous material to micro &nano Level and blending of Metallic powder for making uniform composite material using Planetary Ball mill.

- Development of equipment’s and its subsystems for Nano Metrology and Characterisation

| Centre Head | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

|

Mr. Prakash Vinod | Joint Director | View Profile |

| Group Head | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

| Scientists | |||

| Photo | Name | Designation | View Profile |

|---|---|---|---|

|

Mr. Murugan A | Scientist - C | View Profile |

|

Mrs. Sarmistha Dhan | Scientist - D | View Profile |

|

Mr. Kumar Abhinav | Scientist - C | View Profile |

| Technical Staff | |||

| Photo | Name | Designation | Phone (Office) |

|---|---|---|---|

|

Dr. Aravinda L S | Technical Officer A | 080-22188385 |

|

Mr. Basavaraju Uppara | Technical Officer A | 080-22188385 |

|

Mrs. Shishuma D S | Senior Technical Assistant - I | 080-22188385 |

|

Mr. Umesha G M | Senior Technical Assistant - I | 080-22188255 |

| Administration | |||

| Photo | Name | Designation | Phone (Office) |

|---|---|---|---|

| Sorry, No Staff are Matched Your Criteria. | |||

- Development of equipment’s and its subsystems for Nano Metrology and Characterisation.

- High resolution imaging using Field Emission Scanning Electron Microscopy / Focused Ion Beam (FESEM / FIB) in micro and nano scales for surface morphology and topography of the new material developed.

- Chemical composition analysis and elemental mapping using EDX for determining the material composition, quality check and failure analysis.

- Atomic scale imaging and crystallographic studies on the materials used for new product development using HRTEM.

- Identification of crystalline phases, Determination of Unit cell dimensions, Residual stress measurement, Retained Austenite etc., using X-Ray Diffraction

- Analysis of microscopic phase distribution, surface roughness, 3D topography using the scanning probe microscopy.

- Mechanical characterization like hardness, elastic modulus, friction coefficient, adhesion test and fracture toughness of thin films and coatings using Nanoindentor.

- Specific surface area of the materials with micro pore and meso pore measurements using surface area analyser.

- Composition of material, phase identification, stress/strain, quantitative analysis of amount of material and phase transition of material using RAMAN Spectroscopy.

- Analysis of the bonding signature, functional groups and composition of the materials using FTIR analysis.

- Grinding of brittle - Fibrous material to micro &nano Level and blending of Metallic powder for making uniform composite material using Planetary Ball mill.

Completed Projects:

Development of portable compact Scanning Tunneling Microscope (STM)

Objective

- To develop a 3 directional closed loop translational anopositioning stage that has high resolution, better accuracy, good repeatability and also having minimum decoupled motion between axes

Deliverable:

- Two Portable Scanning Tunneling Microscope prototypes having range: XY – 600 nm, Z - 200 nm with resolution in XY – 0.01 nm, Z - 0.003 nm and capable of obtaining surface topography conductive sample.

- Publications: 1

- Patent: 2 (filed)

- Trademark: 2 Registered

Development of Micro Stereo Lithography System

Objective:

- Development of Microstereolithography (MSL) setup for additive manufacturing of polymeric micro-components

Deliverables:

- Polymeric micro-components and to serve industries related to Biomedical, MEMS, Semiconductor field etc.

- Compact MSL equipment which will provide economical and portable alternative to expensive LASER based MSL

- Polymeric Micro Needle for Drug Delivery and for Biopotential measurement (EEG, ECG, EMG EOG etc.,)

Ongoing Projects:

DSIR’s Study project on “Alternate material for improving response and damping properties of machine tool structures”

Objective:

- Interacting the user industries (Strategic, R&D Institutes, Private industries) regarding the demands of alternate material for machine tool structure with their scientific & application requirements.

- Benchmarking of indigenous technology with respect to global scenario in alternate material for machine tool structures through literature survey, user feedbacks, etc.

Deliverables:

- Benchmarking of indigenous technology with respect to global scenario in development of alternate material for machine tool structure

- Demands, trends in alternate material technology

- Opportunities and challenges in alternate material technology

- Scope, Needs & Market Potential for alternate material structure technology in our country

- Atomic Force Microscope

- Make& Model:Veeco Dimension V SPM

- For industry: Rs.3000 Per hour &Rs.1000 Per Sampling*+GST

- For academics: Rs.2000 Per hour&Rs.700 Per Sampling*+GST

Mrs. SarmisthaDhan (Scientist-C):

Email: sarmistha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188390

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

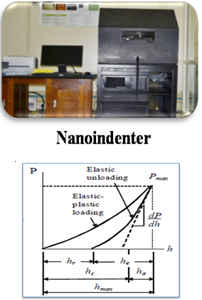

- Nanoindenter

- Make & Model: KLA Tencor, G200

- For industry: Rs.3100 Per hour + GST

- For academics:Rs.2100 Per hour + GST

Mrs. SarmisthaDhan (Scientist-C)

Email: sarmistha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188390

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Micro hardness Tester

- Make& Model: CLEMEX Dual MMT-X7B

- For industry: Rs.1200Per hour &Rs.800 Per Sampling* + GST

- For academics: Rs.800Per hour &Rs.500Per Sampling* + GST

Mr. Kumar Abhinav (Scientist-C)

Email: abhinav[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- XRD

- Make& Model: Bruker D8 Advance

- For industry: Rs.2800 Per hour + GST

- For academics: Rs.1900 Per hour + GST

Mr. Kumar Abhinav(Scientist-C)

Email: abhinav[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Optical Profiler

- Make& Model: Veeco NT9100

- For industry: Rs.2900 Per hour &Rs.600 Per Sampling* + GST

- For academics: Rs.1900 Per hour &Rs.400 Per Sampling* + GST

Mrs. Shushma D S (Technical Assistant-2)

Email: shishuma[at]cmti[dot]res[dot]in

Land Line: +91-80-22188385

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Confocal Microscope

- Make& Model: Olympus LEXT 4000

- For industry: Rs.2200 Per hour &Rs.600 Per Sampling* + GST

- For academics: Rs.1500 Per hour &Rs.400 Per Sampling* + GST

Mrs. Shushma D S (Technical Assistant-2)

Email: shishuma[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM):

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Raman Microscope

- Make& Model: SEKI Technotron Corp STR-300

- For industry: Rs.3500 Per hour &Rs.800 Per Sampling* + GST

- For academics: Rs.2600 Per hour &Rs.600 Per Sampling* + GST

Mr. Basavaraju Uppara (Senior Technical Assistant-2)

Email: basavaraju[at]cmti[dot]res[dot]in

Land Line: +91-80-22188385

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

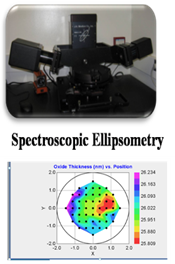

- Spectroscopic Ellipsometer

- Make& Model: J.A. Woollam M2000X

- For industry: Rs.2200 Per hour + GST

- For academics: Rs.1500 Per hour + GST

Mr. Basavaraju Uppara (Senior Technical Assistant 2)

Email: basavaraju[at]cmti[dot]res[dot]in

Land Line: +91-80-22188385

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- FTIR

- Make& Model: Agilent Technologies Cary 660

- For industry:Rs.1500 Per hour &Rs.500 Per Sampling* + GST

- For academics: Rs.1200 Per hour &Rs.400 Per Sampling* + GST

Mr. Basavaraju Uppara (Senior Technical Assistant 2)

Email: basavaraju[at]cmti[dot]res[dot]in

Land Line: +91-80-22188385

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Particle Size Analyzer

- Make & Model: Microtrac Blue Wave

- For industry:Rs.1500 Per hour & Rs.800 Per Sampling* (PSA Wet) + GST

- For academics: Rs.1300 Per hour & Rs.600 Per Sampling* (PSA Wet) + GST

- For industry: Rs.1100 Per hour &Rs.400 Per Sampling* (PSA Dry) + GST

- For academics: Rs.900 Per hour &Rs.300 Per Sampling* (PSA Dry) + GST

Mr. Basavaraju Uppara (Senior Technical Assistant-2)

Email: basavaraju[at]cmti[dot]res[dot]in

Land Line: +91-80-22188385

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Rheometer

- Make & Model: DHR 2- Waters

- For industry:Rs.1500 Per hour + GST

- For academics: Rs.1200 Per hour + GST

Mr. Kumar Abhinav(Scientist-C)

Email: abhinav[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

Equipment Details:

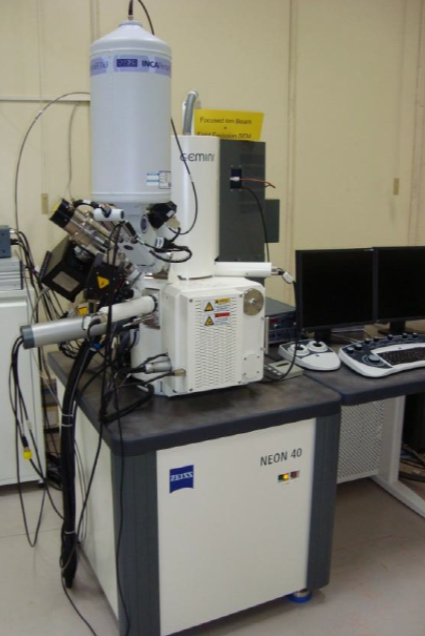

FESEM + FIB:

Make: Carl Zeiss

Model: NEON 40, Germany

EDS:

Make: Oxford Instruments

Model: X Act, UK

EBSD: Make: Oxford Instruments

Model: NORDALYS II, CHANNEL 5 (HKL)

GIS (Gas Injection System): Make: Carl Zeiss

Micro/Nano Manipulator: Make:Kleindiek

Electron Beam Lithography: Make: Raith,

Model: Elphy Quantum

Sputter Coater:

Model: Quorum Technologies

Model: Q150T ES, UK

Analysis:

- Micro & nanostructures, membranes and verification

- Thin films (organic & metallic) and coating morphology, thickness, structure uniformity and compositions

- Failure Analysis- Fractography, porosity, inclusions, material homogeneity and chemistry

- Ion Microscope (Resolution upto 7 nm)

- MEMS & NEMS devices and construction details, bonding (wafer, wire, e-beam weld, seam weld, etc), packing quality, etc

- Particles and Grains (Micro & Nano) morphology, shape, size and distribution

- Concrete, glass, ceramics and geological and minerals samples

- Plastic / polymer, fibers, composites, paper and boards

- Dental & biological samples, plant samples, bio-films, etc

- Hydro-gels (vacuum compatible), paints, emulsions and delamination (peeling)

- Pharmaceuticals samples

- Corrosion evaluations

- Particulates, oil and air filter contamination analysis

- Surface contamination analysis

- Semi quantitative Elemental / chemical Mapping

- Battery analysis

- Forensic analysis: Explosive residues, gunshot residue, ballistics, trace evidence

- EBSD (Crystallographic Analysis with NIST structural Database): Data Acquisition, Phase Reflector file, Creation, Pole Figure, Phase Mapping, Phase Identification

Method of Analysis:

- Published national or international standards (like ASTM, ISO, etc)

- Laboratory developed procedures

- User defined procedures

- Scientific texts or journals

- OEM recommended methodology, etc.

FESEM

- For industry: Rs. 5400 + GST

- For academics: Rs. 3800 + GST

FESEM + EDS

- For industry: Rs. 7200 + GST

- For academics: Rs. 5100 + GST

FESEM + EBSD

- For industry: Rs. 7300 + GST

- For academics: Rs. 5200 + GST

FESEM + FIB

- For industry: Rs. 5700 + GST

- For academics: Rs. 4200 + GST

Sputter Coater

- For industry: Rs. 1400 + GST

- For academics: Rs. 1000 + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

Make: FEI Model: Titan G2 60 300 TEM

Specifications:

Resolution: TEM: 0.2 nm @ 300 kV, STEM: 0.136 nm @ 300 kV

EDX Resolution: 136 eV

Accelerating Voltages: 60 to 300 KeV

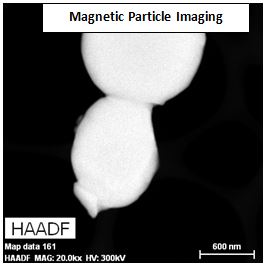

Imaging modes: TEM, STEM-HAADF, BF, DF, EDS, Selected area diffraction, 3D Tomography

Holders: Single Tilt Holder, Double tilt Holder, Heating Holder, Cryo Holder

Analysis:

- Atomic Scale Imaging, and Crystallographic studies,

- Study of multi-layers and structures,

- Defect inspection in semiconductor fabrication process,& Elemental analysis

- Magnetic Particle Imaging and Analysis

- Rubber Composite and Analysis

- Metal Composites and Analysis

- Gap analysis in unconventional Welding process and its elemental Mapping

- Distribution of precious metal nanoparticles in pharmaceutical Syrup

- Crystallographic and Amorphous Behaviour of Drug Molecules

- Elemental Mapping of Different Nano clusters

Method of Analysis:

- Published national or international standards

- Laboratory developed procedures

- User defined procedures

- Scientific texts or journals

- OEM recommended methodology, etc.

TEM

- For Industry: Rs. 12200 + GST

- For Academia: Rs. 8500 + GST

TEM + EDS

- For Industry: Rs. 13500 + GST

- For Academia: Rs 9200 + GST

TEM + EDS + STEM + Diffraction

- For industry: Rs. 14800 + GST

- For Academia: Rs. 10100 + GST

TEM using Heating Holder

- For Industry: Rs. 12500 + GST

- For Academia: Rs. 8500 + GST

TEM Tomography

- For Industry: Rs. 16000 + GST

- For Academia: Rs. 11000 + GST

Charges – per Sample Basis

TEM

- For industry: Rs. 6200 + GST

- For Academia: Rs. 4200 + GST

TEM+ EDS

- For industry: Rs. 6700 + GST

- For Academia: Rs. 4500 + GST

TEM + EDS + STEM + Diffraction

- For industry: Rs. 7500 + GST

- For Academia: Rs. 5000 + GST

TEM using Heating Holder

- For Industry: Rs. 6500 + GST

- .For Academia: Rs. 4500 + GST

TEM Using Cryo Holder

- For Industry: Rs. 6500 + GST

2. For Academia: Rs. 4500 + GST

Dr.Aravinda L S (Senior Technical Assistant-2)

Email: aravinda[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Prakash Vinod (Scientist-F, Centre Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Vacuum furnace

- MTIGSL-1500X-50-UL

- For industry:Rs.800 Per hour + GST

- For academics: Rs.600 Per hour + GST

Mr. Kumar Abhinav(Scientist-C)

Email: abhinav[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Prakash Vinod (Scientist-F, Centre Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Planetary Ball Mill

- Make: Fritsch, Pulverisette 7 Premium Line

- For industry= 1000 Rs/hr + GST

- For Academic = 800 Rs/hr + GST

Mr. Kumar Abhinav (Scientist-C)

Email: abhinav[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

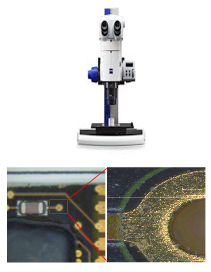

- Stereo Microscope

- Make& Model: Carl Zeiss Discovery V20

- For industry: Rs.900 Per hour + GST

- For acadamics:Rs.700 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Light Microscope

- Make& Model: Carl Zeiss Axio Imager M2m

- For industry: Rs.1000 Per hour + GST

- For acadamics:Rs.750 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Low Speed Diamond Saw

- Make& Model: Struers Minitom

- For industry: Rs.900 Per hour + GST

- For acadamics:Rs.800 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Low Speed Diamond Saw

- Make& Model: Well 3242

- For industry: Rs.1100 Per hour + GST

- For acadamics:Rs.900 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Labopol5

- Make& Model: Struers

- For industry: Rs.650 Per hour + GST

- For acadamics:Rs.500 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

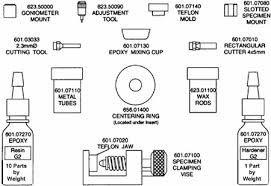

- Disc Punch

- Make& Model: Gatan 659

- For industry: Rs.200 Per hour + GST

- For acadamics:Rs.150 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Disc Grinder and lapping kit

- Make& Model: Gatan 623

- For industry: Rs.600 Per hour + GST

- For acadamics:Rs.500 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Ultrasonic disc Cutter

- Make& Model: Gatan 601

- For industry: Rs.700 Per hour + GST

- For acadamics:Rs.600 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

Equipment’s used: Dimple grinder

Make& Model: Gatan 656

- For industry: Rs.1000 Per hour + GST

- For acadamics:Rs.900 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255,

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Tenupol5 Electrolytic jet polisher

- Make& Model: Struers

- For industry: Rs.1200 Per hour + GST

- For acadamics:Rs.1000 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255,

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Precision Ion Polishing System

- Make& Model: Gatan 691

- For industry: Rs.1700 Per hour + GST

- For acadamics:Rs.1300 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Precision Ion Polishing System

- Make& Model: Gatan 950

- For industry: Rs.1600 Per hour + GST

- For acadamics:Rs.1300 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Cross Section Kit

- Make& Model: Gatan 601

- For industry: Rs.450 Per hour + GST

- For acadamics:Rs.400 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Hot Plate

- Make& Model: Gatan 623

- For industry: Rs.200 Per hour + GST

- For acadamics:Rs.150 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- laboforce3

- Make& Model: Struers

- For industry: Rs.600 Per hour + GST

- For acadamics:Rs.500 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Sputter coater

- Make& Model: Quorum Q150T ES

- For industry: Rs.1400 Per hour + GST

- For acadamics:Rs.1000 Per hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Low speed diamond saw, Labopol5,

disc Punch, Hot plate, Disc Grinder, Dimple grinder, PIPS, Advanced plasma cleaner.

- For industry: Rs.7000 Per Sample + GST

- For academics: Rs. 6000 Per Sample + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Low speed diamond saw, Labopol5,

disc Punch, Hot plate, Disc Grinder, Dimple grinder, PIPS, Advanced plasma cleaner.

- For industry: Rs.7000 Per Sample + GST

- For academics: Rs. 6000 Per Sample + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Hot plate, Disc Grinder, Dimple

- grinder, PIPS, Advanced plasma

cleaner.

- For industry: Rs.4500 Per Sample + GST

- For academics: Rs. 3500 Per Sample + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255,

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Knife Maker and Ultra Microtome

- Make& Model: Leica EM KMR3/ Leica EM UC7

- For industry: Rs.2500 Per Sampling/hour + GST

- For academics: Rs.2000 Per Sampling/hour + GST

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

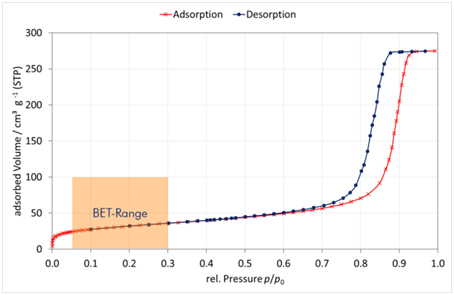

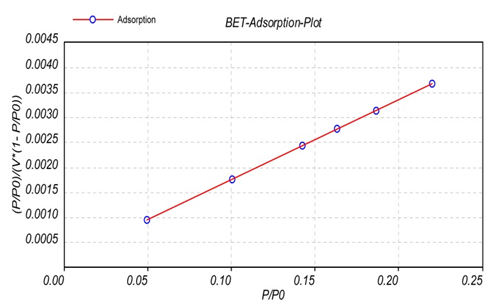

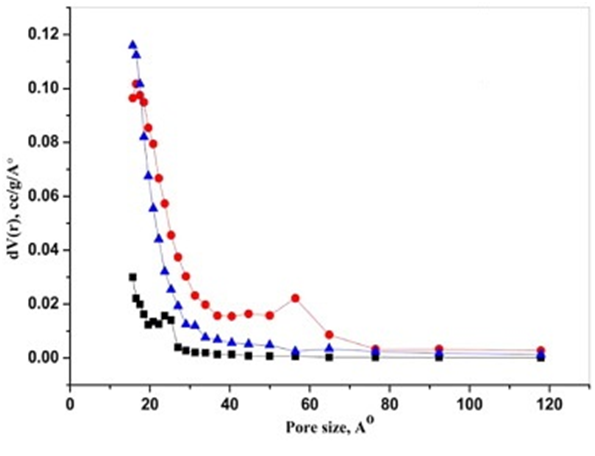

- Micropore&Mesopore measurements,

- Surface area Analysis and pore size distribution of Metal powders, Carbon powders, Nano materials , Zeolites etc

- Types of active sites, Number of active sites, Reactivity of active sites and Stability of active sites.

Method ofAnalysis:

- Published national or international standards

- Laboratory developed procedures

- User defined procedures

- Scientific texts or journals

- OEM recommended methodology, etc.

Make: Quantachrome Model: Autosorb-iQ-MP-XR &ChemBET PULSAR

Specifications:

Surface area range: From 0.01m2/g

Pore size range: 3.5 to >4000 Å

BET/Mesopore Capable: (P/Po >1 x 10-3)

Micropore capable:(P/Po<10-4)

Features: Built-in Degasser Stations & Degas Cold Trap

per hour(As on April 2020)

Physisorption

- Industry: Rs1200 +GST

- Academia: Rs900+GST

Chemisorption

1.Industry: Rs1100 + GST

2.Academia: Rs900 +GST

Dr.Aravinda L S (Senior Technical Assistant-2)

Email: aravinda[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Prakash Vinod (Scientist-F, Centre Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- RF Source

- Vacuum/Gas Pumping System

- Vacuum Gauge(Compact pirani gauge

- Precision Gas flow Control

Sample preparations for TEM Analysis

Mr. Murugan A (Scientist-C):

Email:murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM):

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Specimen holder for 3 mm dia.

specimens - Specimen holder for 2.3 mm dia. specimens

- Specimen holder, 10 mm diaphragm for pre-thinning

- Set of jets, 1 mm bore

Sample preparations for TEM Analysis

Mr. Murugan A (Scientist-C):

Email:murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM):

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Milling Angle: +10° to -10° in steps of 1°

- Beam energy: 100 eV to 6 KeV

- Beam Diameter: Adjustable using gas flow

- Beam Modulation: Single or double sector

- Ion current density: 10mA/cm2 peak

- Sample size: 2.3mm or 3mm

- Stage rotation speed: Variable from 1 to 6 rpm

- CCD Active area: 3.2mm x 2.4mm

Sample preparations for TEM Analysis

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- The Gatan Specimen Mounting Hot Plate is thermostatically controlled at the precise mounting temperature of 130°C.

- The hot plate also contains recesses to hold the specimen mounts in place when bonding the discs.

Cross section Sample preparations for TEM Analysis

Mr. Murugan A (Scientist-C)

Email:murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Quickly and easily prepare XTEM samples for TEM study of interfaces with greater consistency

- Used in conjunction with the ultrasonic cutter, cut rectangular areas of interest from bulk material to produce coated, stacked, and pressure-cured sections with minimum glue thickness (<1 µm)

- Suitable for preparing cylinder sections for dimpling prior to ion milling

Cross section Sample preparations for TEM Analysis

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Platen speed (rpm)50-500 variable adjustable knob

- Platen rotation anticlockwise

- Head rotation anticlockwise

- Machine function manual

- Water function manual

Lapping, grinding, polishing by quick simple exchange of grit papers

Mr. Murugan A (Scientist-C)

Email:murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Large specimen area

- Strong transparent area

- Direct preparation of TEM specimens

- Accurate depth and thickness control

- Micro positioning, improved auger profiling

Sample preparations for TEM Analysis

Mr. Murugan A (Scientist-C)

Email:murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Manual turned frequency driver to optimize cutting speed

- Spring loaded platform applies constant force couples with magnetically held table to prevent lateral movement

- Broad selection of shape and size cutting tools

Sample preparations for TEM Analysis

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Unique piston rim design

- Exact fit of the cutting and support pistons

- Strong metal base

- Easy to see and remove punched area/disc

Sample preparations for TEM Analysis

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Grinder weights limits the max polishing pressure

- Ultra fine thread and pre loading of the specimen drive screw

- Large dia polishing face and precise fit of the specimen mount

Sample preparations for TEM Analysis

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Vertical arrangement of wire

- Height adjustable working area

- Infinitely variable wire speed

- Linear feed(60mm)

- User friendliness

- Precision cut off with diamond embedded wire

- Sectioning of brittle materials

- TEM Sample Preparation work

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Semi-automatic specimen mover for the preparation of 1-3 specimens

- Automatic specimen mover for the preparation of mineralogical specimens

Lapping, grinding, polishing by quick simple exchange of grit papers

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Universal specimen holders

- Weight 0-350g, which is used to set the cutting pressure

- Three different types of cutting wheels for sectioning

- The transparent protection screen allows visual examination during the cut-ting process without the risk of Splashing

- Sectioning of ferrous metal samples

- Sectioning of nonferrous metal samples

- Sectioning of minerals

- Sectioning of tooth samples

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Electronic data transfer for reporting user, specimen Knife usage monitoring

- Fully motorized knife stage and Auto-Trim function

- Brightness-controlled multi-LED illumination and LED spot illumination

- Advance control from

- 1nm to 100nm in steps of 1nm

- 100 to 2500nm in steps of 10nm

- 2500 to 15000 nm in steps of 500nm

TEM sample preparation of Biological samples, Polymer and soft samples

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Objectives 5x, 10x, 20x, 50x, 100x

- XY Stage with travel range 4” x 4”

- Contrast modes: BF, DF, POL & DIC

Motorization for reproducible component settings and automated processes

Homogeneous illumination in both transmitted light and fluorescence applications

Quality Control, R&D, failure analysis, Topography analyses etc.

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

| Parameter | Value |

| Main Disc Speed | 100- 1,100 Rpm |

| Sample Quantity | 0.5ml to 70ml |

| Grinding Bowl | Tungsten Carbide & Zirconium Oxide |

Grinding of brittle – Fibrous material to Nano & Micron Level

Development of Nano powders from ceramics and metals

Mr. Kumar Abhinav(Scientist-C)

Email: abhinav[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361, Mobile: +91 8884004124

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Zoom optics: 20:1

- Magnification of up to 345x (with eyepiece 10x)

- Resolution of 1000LP/mm (with objective Plan Apo S 2.3x)

- Optical Zoom range: 8-160x

- Filters: Daylight, UV & ND

Features

- Plan-Apochromatic corrected microscope

- Built in and coded double iris diaphragm for DOF control

- Real time display of magnification , resolution, DOF, etc.

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Umesha G M (Technical Assistant-1)

Email: umesha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188255

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

FESEM (SESI, In-Lense and BSE)

- Type: Schottky Field Emission, GEMINI Column

- Accelerating Voltage: 100V-30 kV

- Beam current: Upto 20nA

- Resolution: 1.1 nm @ 20 kV

- Magnification: 30 X to 1000 kX

- Stage: 6 Axes Eucentric

FIB

- Type: LMIS (Gallium, Ga )

- Accelerating Voltage: 2-30 kV

- Probe current: 1 pA to 50 nA

- Minimum Feature Size: 22 nm

- Stage: 6 Axes Eucentric

Ion Microscope:

- Resolution-Better than 7 nm

EDS:

- Detection: From Boron (B) to Thorium (Th)

- Modes: Point, Area analysis, Elemental Mapping, Metal oxides by oxygen stoichiometry for known oxidation states.

EBSD:

- NORDALYS II, CHANNEL 5

Softwares: - Flamenco-Data Acquisition

- Twist-Phase Reflector file creation

- Mambo- Pole Figure

- Tango- Mapping

- Phase Identification

- NIST structural Database

Gas Injection System:

- 5 Gas chemistry (Pt, W, SiO2, Carbon, XeF2),

- Minimum Feature Deposition: 40 nm

Micro/Nano Manipulator for TEM lamella preparation

Electron Beam Lithography

- Micro & nanostructures, membranes and verification

- Thin films (organic & metallic) and coating morphology, thickness, structure uniformity and compositions

- Failure Analysis- Fractography, porosity, inclusions, material homogeneity and chemistry

- MEMS & NEMS devices and construction details, bonding (wafer, wire, e-beam weld, seam weld, etc), packing quality, etc

- Particles and Grains (Micro & Nano) morphology, shape, size and distribution

- Concrete, glass, ceramics and geographical and minerals samples

- Plastic / polymer, fibers, composites, paper and boards

- Dental & biological samples, plant samples, bio-films, etc

- Hydro-gels (vacuum compatible), paints, emulsions and delamination (peeling)

- Pharmaceuticals samples

- Corrosion evaluations

- Particulates, oil and air filter contamination analysis

- Surface contamination analysis

- Semi quantitative Elemental/chemical Mapping

- Battery analysis

- Forensic analysis: Explosive residues, gunshot residue, ballistics, trace evidence

- EBSD(Crystallographic Analysis with NIST structural Database): Data Acquisition, Phase Reflector file, Creation, Pole Figure, Phase Mapping, Phase Identification

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243,

- Surface area range: From 0.01m2/g

- Pore size range: 3.5 to >4000 Å

- BET/Mesopore Capable: (P/Po >1 x 10-3)

- Micropore capable:(P/Po<10-4)

- Features: Built-in Degasser Stations & Degas Cold Trap

- Micropore & Mesopore measurements,

- Specific surface area of phases,

- Types of active sites,

- Number of active sites,

- Reactivity of active sites and Stability of active sites

Mrs. Basavaraju Uppara (Senior Technical Assistant-2)

Email: basavaraju[at]cmti[dot]res[dot]in

Land Line: +91-80-22188385

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Load resolution : 1nN

- Displacement Resolution : 0.0002 nm

- Maximum Load : 500 mN

- Maximum depth : 500 μm

- Insitu imaging : 100 x 100 μm

- LFM : > 250 mN

- Hardness and Modulus measurement

- Fracture Analysis

- Paints and coatings

- Metals and Ceramics

- Bio-materials

- Metal-Matrix Composites

- Polymers

- Thin Films

Mrs. BasavarajuUppara (Senior Technical Assistant-2)

Email: basavaraju[at]cmti[dot]res[dot]in

Land Line: +91-80-22188385

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Spectral measurement range : 6500-400 cm-1(MIR),

500-20 cm-1 (FIR) - Spectral resolution : <0.06 cm-1

- Wave number resolution : 0.005 cm-1 @ 2200 cm-1

- Signal to noise ratio : 16000:1 peak to peak for 5 sec @ 4cm-1

- Measurement mode : Transmission, Absorption and ATR (Diamond and Ge crystal)

Analyse composition of material

Analyse functional group

Analyse bonding signature in the material.

Mrs. BasavarajuUppara (Senior Technical Assistant-2)

Email: basavaraju[at]cmti[dot]res[dot]in

Land Line:+91-80-22188385

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Heating room temp to 1400⁰C

- 10°C / min (RT~1000°C)

- 5°C / min (1000°C~1400°C)

- Heating Zone Length: 6″ (152 mm)

- Heating Zone Weight: 100gms

- Powder Sintering

- Heat Treatment

- Degassing

Mr. Kumar Abhinav (Scientist-C)

Email: abhinav[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361,

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Type: Magnetron sputter (cold)

- Grain size: 0.5 nm for Cr Applications

- Magnetron Sputtering for many metal and alloys (Au, Ag, Au/Pd, Ni, Cu, Ti, Cr, etc)

- Carbon Evaporation

- Metal Evaporation

- Aperture (SEM) cleaning

Mr. Murugan A (Scientist-C)

Email: murugan[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361,

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Resolution: TEM: 0.2 nm @ 300 kV, STEM: 0.136 nm @ 300 kV

- EDX Resolution: 136 KeV

- Accelerating Voltages: 60 to 300 KeV

- Stage: 5 axis, Range: X, Y: ± 1 mm, Z : ± 0.375 mm, α : ± 40° , β : ± 30°

- Imaging modes: TEM, STEM-HAADF, BF, DF, EDS, Selected area diffraction, 3D Tomography

- Atomic Scale Imaging,

- Crystallographic studies,

- Study of multi-layers and structures,

- Phase transformations,

- Defect inspection in semiconductor fabrication process,

- Elemental analysis

Dr. Aravinda L S (Senior Technical Assistant-2)

Email: aravinda[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361,

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Minimum Torque (nN.m) oscillation : 2

- Minimum & Maximum Frequency (Hz) : 1.0E-07 & 100

- Minimum & Maximum Angular Velocity (rad/s): 0-300 Maximum Normal Force (N) : 50

- Torque Resolution (nN.m) : 0.1

- Normal Force Sensitivity (N) : 0.005

- Normal Force Resolution (N) : 0.5

- Antiperspirant/Deodorant

- Shampoos

- Creams/Lotions

- Paints and coatings

- Thickners

- Food products

Mr. Kumar Abhinav (Scientist-C)

Email: abhinav[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Lasers : Blue 405 nm and Red 780 nm

- Measuring range : 0.02 to 2800 μm

- Data handling : Volume, Number and Area distributions

- Analysis : Dry powder and liquid suspension

- Particle size identification and its distribution in Cosmetics

- Pharmaceutical

- Food

- Metal industry

- Paints

- Pigments and Dyes

- Cements and Chemical Industry.

Mrs. Basavaraju Uppara(Senior Technical Assistant-2)

Email: basavaraju[at]cmti[dot]res[dot]in

Land Line: +91-80-22188385

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- मापने वैल्यूम: 150 X 150 X 40 मिमी

- स्पेक्ट्रल रेंज: 250 – 1000 एनएम स्पेक्ट्रल रिज़ॉल्यूशन: 1.6 एनएम

- परत की मोटाई

- ऑप्टिकल स्थिरांक

- कंपोजिशन/ क्रिस्टलीयता / डोपिंग

- सरफेस और इंटरफैसिअल रफनेस

- ग्रेडिंग / एकरूपता एनीसोट्रॉफी

- भौतिक प्रभाव जो सामग्री के ऑप्टिकल-गुणों में परिवर्तन को प्रेरित करता है

श्री बसवाराजू उप्परा (वरिष्ठ तकनीकी सहायक -2)

ईमेल: basavaraju[at]cmti[dot]res[dot]in

दूरभाष: + 91-80-22188385

श्री प्रकाश विनोद (वैज्ञानिक-एफ, केंद्र प्रमुख एसएमपीएम)

ईमेल: prakashv[at]cmti[dot]res[dot]in

दूरभाष: + 91-80-22188243

- XY range : 100 x 85 mm or more

- XY Resolution : 0.5 m

- Objectives : Up to 100x

- Lateral Optical (XY) Resolution : 200 nm

- Vertical Resolution : 10 nm

- Max Sample Size : 100x100x40 mm

- 3D imaging Surface topology

Mrs. Shushma D S(Technical Assistant -2)

Email: shishuma[at]cmti[dot]res[dot]in

Land Line: +91-80-22188385

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Max Sample Size : 150 X 150 X 80 mm

- Field of view (X, Y) : 0.3mm @ 50x& 0.17mm @ 100x XY

- Optical Resolution : 0.55 μm @ 50x 0.36μm @ 100x

- Z Resolution : 0.1 nm, Step Height Accuracy1%

- Topography

- Surface Finish

- Critical Dimensions

- Radius of Curvature

- MEMS

- Semiconductors & ICs

- Dynamic MEMS Technology

Mrs. Shushma D S(Technical Assistant -2)

Email: shishuma[at]cmti[dot]res[dot]in

Land Line: +91-80-22188385

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Configuration : Vertical Theta/2 Theta

- Max. Usable angular range : 110° < 2 Theta ≤ 168° Smallest addressable increment : 0.0001°

- Anodes : Cu, Cr & Co

- Detectors : Scintillation &Lynxeye

- Application software : EVA, LEPTOS & TOPAS

- Identification of crystalline materials

- Sample purity measurement

- Determination of Unit cell dimensions

- Residual stress measurement

- Determination of Degree of Crystallinity

Mr. Kumar Abhinav (Scientist-C)

Email: abhinav[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Load resolution: 1nN

- Displacement Resolution: 0.0002 nm

- Maximum Load : 500 mN

- Maximum depth: 500 μm

- Insitu imaging : 100 x 100 μm

- LFM : > 250 mN

- Hardness and Modulus measurement

- Fracture Analysis

- Paints and coatings

- Metals and Ceramics

- Bio-materials

- Metal-Matrix Composites

- Polymers

- Thin Films

Mrs. Sarmistha Dhan (Scientist-C)

Email: sarmistha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188392

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Load Range: 1gf – 2000gf

- Load duration: 5 to 99 sec

- Objective: 25X, 100X, 400X

- Individual phase analysis

- Case hardened components depth measurements

- Coating hardness

Mr.Kumar Abhinav (Scientist-B)

Email: abhinav[at]cmti[dot]res[dot]in

Land Line: +91-80-22188361

Mr. Prakash Vinod (Scientist-F, Center Head SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

- Resolution: 2 X 2 X 0.05 nm

- Open-Loop head: X-Y scan range: 100 μm; Z scan range: 5.5 μm

- Closed Loop Scanner: X-Y scan range: ~ 90μm; Z scan range: ~15 μm

- Sample Size:150 X 12 mm, 150 X 9 mm

- Microscope optics: 150 μm to 675 μm viewing area

- Nano scale 3D surface topography & texture analysis

- Analysis of micron &nanoscale phase distribution &imaging

- Mechanical &physical property measurements

- Defect imaging in MEMS

- IC failure analysis

Mrs. SarmisthaDhan (Scientist-C)

Email: sarmistha[at]cmti[dot]res[dot]in

Land Line: +91-80-22188392

Mr. Prakash Vinod (Scientist-F, Center Head – SMPM)

Email: prakashv[at]cmti[dot]res[dot]in

Land Line: +91-80-22188243

Nano-Characterisation Laboratory Accreditation

1. The RITES, RDSO (Ministry of Railways) approved Nanocharacterisation facilities of CMTI, as alternative test laboratory for SEM, EDXA & XRD tests of porcelain Insulators as per RDSO’s specification no. TI/SPC/OHE/INS/0070 dated 10.04.2007.

1. Scanning Tunnelling Microscope, Nano Avalok

2. Nano Positioning stage

Publications

1. Vithun S N, Narendra Reddy T, Prakash Vinod. “Investigation on Nanoscale Imaging of Gold Sputtered Sample by Scanning Tunneling Microscope”, Materials Today: Proceedings 22, 2020. 2439–2445.

2. Manjunath B N, Vinod A R, Abhinav K, Verma S K, Ravi sankar M. “Optimization of process parameters for deposition of colmonoy using directed energy deposition process” materials today proceedings, 2019.

3. SarmisthaDhan, Dova Siva Sai Charan, MuruganAngamuthu, Ashish Varade “Characterization and analysis of Au-Pd metal alloy thin films deposited by DC sputtering using a Scanning Tunneling Microscope for automobile application”, Proceedings of the International Conference on Materials and Manufacturing Methods (3M – 2019), NIT Trichy, pp 1326-1329

4. T. S. Kavithaa, SarmisthaDhan, L. Rangaraj, S. S. Avadhani, “Mechanical characterization of PM Cu/SiC composites for aerospace thermal management applications”, Proceedings of 2nd International Conference on Advanced Materials and Processes for Defence Applications, ADMAT-2019, ADMAT2019-Abstract Booklet, pp. 105

5. Ankit K, Ashish Varade, Niranjan Reddy K, SarmisthaDhan, Chellamalai M, Balashanmugam N, Prasad Krishna “Synthesis of high hardness IR optical coating using diamond-like carbon by PECVD at room temperature” Published in Diamond & Related materials Journal with impact factor 2.5 in September ’2017

6. Ankit K, Ashish Varade, Niranjan Reddy K, SarmisthaDhan, Chellamalai M, Balashanmugam N, Prasad Krishna “Synthesis of high hardness, low COF diamond-like carbon using RF-PECVD at room temperature and evaluating its structure using electron microscopy ” Published in Diamond & Related materials Journal with impact factor 2.5 in Nov ’2017

7. Ankit K, Ashish Varade, Niranjan Reddy K, SarmisthaDhan, Chellamalai M, Balashanmugam N, Prasad Krishna “Development of Implementable Diamond-like Carbon Coating for Improving Scratch, Wear and Optical Properties for Practical Industrial Applications” Presented in International conference on Precision, Meso, Micro and Nano Engineering (COPEN 10 2017) in December 07 – 09, 2017

8. SarmisthaDhan, Ashish Varade, Alyosius Daniel “Role of nanocharacterization in dentistry” Published in MTT Journal Nov 2016

9. Narendra Reddy T, Vithun S N, Prakash Vinod, Shrikantha S Rao, Mervin Herbert. “Design & Implementation of Closed loop Nanopositioning Stage”, presented at 1st International Conference on Nanoscience and Nanotechnology 2016 (ICNAN 2016) organized at VIT, October, 2016.

10. Narendra Reddy T, Vithun S N, Prakash Vinod, Shrikantha S Rao, Mervin Herbert. “A high speed portable XY flexure-based Nanopositioning stage, International Journal for Scientific Research & Development. Vol.4, January 2016, Issue 6, Pages 868-87

11. Narendra Reddy T, Vithun S N, Prakash Vinod, Shrikantha S Rao, Mervin Herbert. “A compact XY flexure based nanopositioning stage for Scanning Probe Microscope (SPM)”, Manufacturing Technology Today. Vol.15, October 2016, Issue 10, Pages 3-8.

12. Narendra Reddy T, Vithun S N, Prakash Vinod, Shrikantha S Rao, Mervin Herbert. “Development of high bandwidth flexure based stage for Nanopositioning applications”, Advanced Science Letters- American Scientific Publishers, Vol.24, No.8,2016

13. Vithun S N, Prakash Vinod, Narendra Reddy T, Shashi Kumar P V. “Design and analysis of a single-flexure parallelogram mechanism-based X-Y nanopositioning stage”, Int. J. of Mechatronics and Manufacturing Systems Vol.9, January 2016 No.1, pp.24 – 35

14. Murugan A, Niranjan Reddy K, Mallappa H K, Khushboo, Shashikumar. “Effect of change in acceleration of gravity in accuracy of electronic levels”, at 9th International Conference on “Advances in Metrology, 24-26 February, 2016, CSIR-NPL, New Delhi.

15. SarmisthaDhan, Megha Agrawal, C Ramachandra "Characterization Method for Micro Beams Based Pressure Transducers by Nanoindentation Technique" Presented at ICMMM 2014 International conference held at IIT Chennai on 8th August 2014.

16. “Mechanical Characterisation of UV Photo-Polymerised PMMA with different Photo-Initiator Concentration” at ICPC-2014 Conference held at NITK-Suratkalbetween 18-19 Dec 2014.

17. Murugan A, Ramesh R. “Enhanced Emission Properties of Carbon Nanoparticles by Hydrothermal Method” National Conference on Micro and Nanofabrication 2013 (mnf 2013) at CMTI, Bangalore, India, Page: 290-293.

18. Murugan A, Ramachandra C, Sarma V A P, Jagadish M L “Laser Assisted Mask Fabrication for Prototype Product Development” International Conference on Precision, Meso, Micro and Nano Engineering (COPEN-8: 2013), December 13-15, 2013, NIT Calicut, Kerala, India. 736-739.

Patents

1. “A Low Frequency Portable Vibration Isolation System”Indian Patent Application No: 201941032175 dated 08.08. 2019

2. “An Acoustic Enclosure System” Indian Patent Application No: 201941032175 dated 08.08. 2019

3. “Testing of Writing Instruments” Indian Patent Application No: 201641038811.

Trademarks

1. Scanning Tunneling Microscope, NanoAvalok STM (Word)

Indian Patent Office Application No.:3863098, dated: 29.10.2018

2. Scanning Tunneling Microscope, NanoAvalok STM (Logo)

Indian Patent Office Application No.:3863099, dated: 29.10.2018

Mr. Prakash Vinod

Scientist-F & Centre Head –Smart Manufacturing,

Precision Machines Tools and Aggregates

Central Manufacturing Technology Institute (CMTI)

Tumkur Road, Bengaluru - 560022

Phone (office): +91-80-22188243, 23371516

Mobile: +91-9449842680

Fax: +91-80-23370428

E-mail: prakashv[at]cmti[dot]res[dot]in