Salient Features:

- Hydrostatic oil Bearing with theoretical infinite lifetime

- True motion, zero stick-slip, zero backlash & Maximum positioning accuracy

- High stiffness for Heavy loads & excellent geometric performance

- High Dampening effect from oil film for vibration from machining process

- Thermally stable, with heat dissipation by oil & additional water cooling

- Direct drive with Integrated Linear motor with low cogging force

- Ultra precision Linear Glass Scale for position feedback

- Integral high performance bellows for protection of Bearing & electronics from Contamination

Specification:

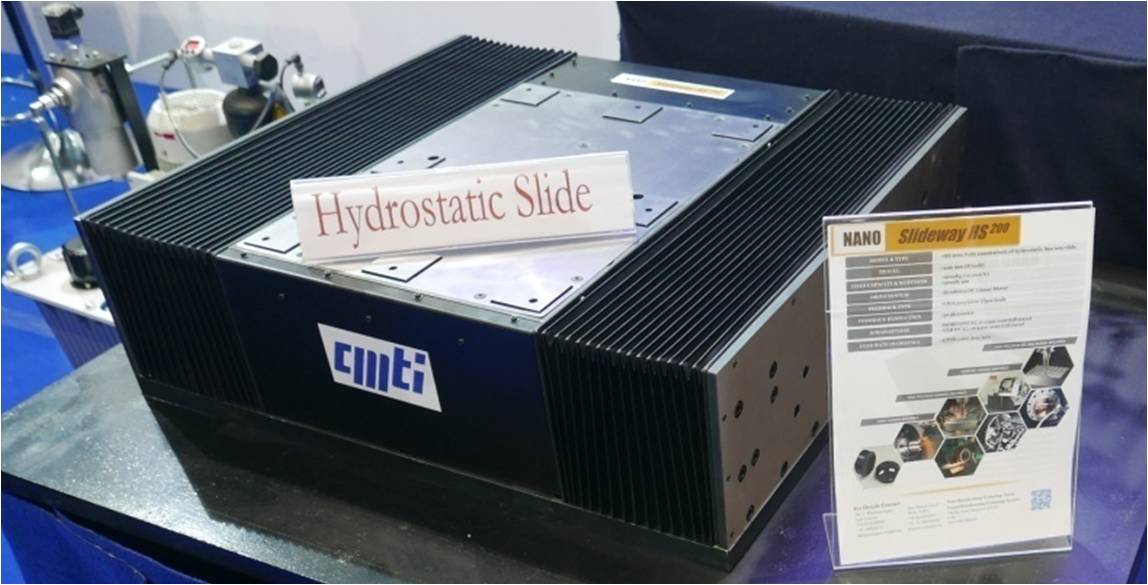

Model & type HS200 : Fully constrained oil hydrostatic, box way slide

Travel : 200 mm (8 Inch)

Load capacity : 1000Kg (10,000 N)

stiffness : 1000N/μm

Drive system : Brushless DC Linear Motor

Feedback type : Ultra precision Glass Scale

Feedback resolution : 32 Pico meter

Straightness : Horizontal :0.2 μm over full travel,

Vertical : 0.4 μm over full travel

Feedrate (working) : Upto 1000 mm/mina

Work piece accuracies:

Level of Development:

Status of Commercialization:

Ready for Technology Transfer

Major Raw materials Utilised:

- Standard materials commonly used for engineering product development, such as various categories of steel alloys, aluminum alloy, granite, etc.

- Standard components include linear motors and drives, Linear scale, micrometer, power pack, hydraulic valves, other mechanical & electrical elements.

Major Plant Equipment and Machines required:

- Ultra-precision micro machining Center, Wire cut EDM, Precision Turning and Milling Machine, Precision Grinding Machine, Laser interferometer, Ultra precision dimension, form and surface roughness equipments

Techno economics:

- No Indian Machine tool manufacturer offers hydrostatic slides as commercial elements and neither machine tool with integrated hydrostatic slides.