Salient Features:

- Good metallurgical bonding

- No thermal distortion

- Controlled heat affected zone

- Controlled dilution

- Good interfacial bonding

- No cracks

- No porosity

Specification:

- Maximum build volume : 300X 300X 300 mm

- Deposition material : Steel, Inconel

- Substrate material : Any metal

Work piece accuracies:

Level of Development:

TRL 8

Status of Commercialization:

Ready for Technology Transfer

Major Raw materials Utilised:

- Steel powders

- Inconel powders

- Argon and Helium gases

Major Plant Equipment and Machines required:

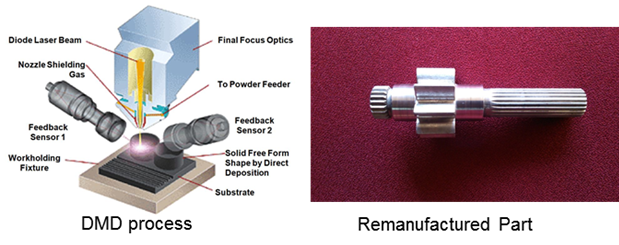

Direct Metal Deposition additive manufacturing machine and General purpose manufacturing facilities like lathe, milling and grinding machines etc.

Techno economics:

Potential exists for Remanufacturing of expensive engineering parts for Aerospace, Automotive,Energy, Tooling etc. High quality remanufactured parts can be Produced saving material, energy,time and cost.

Technology Package

Methodology & Process parameters